Introduction: What is Electrical Crimping Geometry?

When it comes to electrical installations, the choice of Crimp Geometry (or Crimping Shape) significantly influences the reliability and performance of connections. Crimp geometry essentially refers to the shape and design of crimped electrical connections (e.g. Hexagonal, Square, etc), which influence electrical performance, mechanical strength and reliability. Elpress, leader in crimping systems and electrical solutions, offer tools and die sets featuring a range of Crimp Geometries (or Crimping Forms), each suitable for certain applications but all designed to exceed industry demands.

What is Crimping?

Electrical Crimping is a method of joining a connection element (terminal, lug, ferrule, etc) with an electrical conductor or wire, by permanently deforming the element on the conductor with a Crimper (Crimping Tool). The process begins by stripping the wires and, in some cases like transformer winding crimping or certain sector-shaped aluminium conductors, prerounding them. The stripped wire is then inserted through the opening of the connection element, and the crimper is used to squeeze the element with a high force against the wire, forming a secure and reliable connection.

Understanding Crimping Technology in Electrical Installations

Crimping Technology plays a vital role in ensuring secure and reliable electrical connections. Effective electrical crimping involves creating a strong bond between cables and terminals, using various crimping geometries to achieve optimal results. The Crimping Process enhances the overall integrity of electrical installations by preventing wire fatigue and ensuring dependable electrical conductivity.

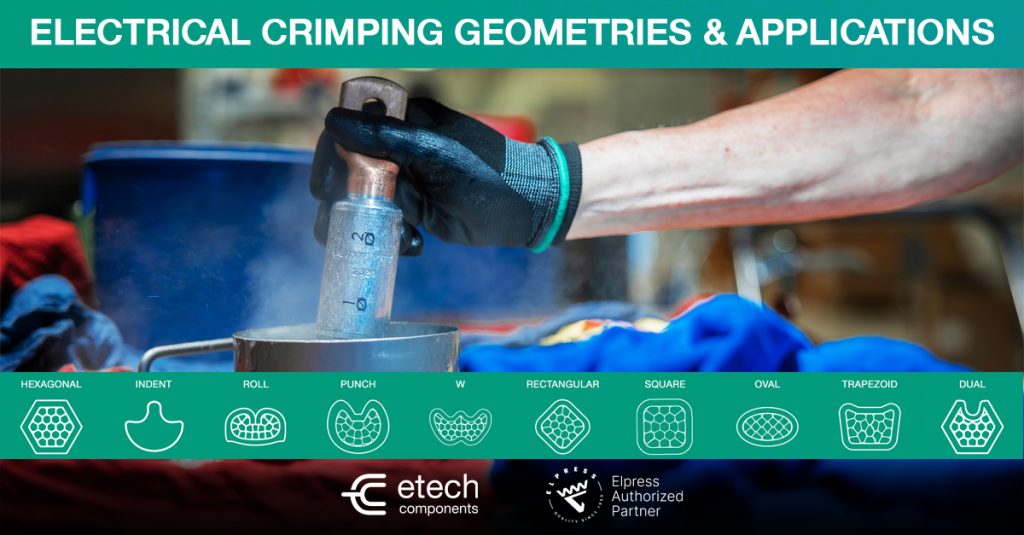

Electrical Crimping Geometry & Applications

Common Crimping Geometries

One of the most common geometries (crimping forms) is Hexagonal Crimping, which serves as the backbone of many electrical installations. Hexagonal crimping provides robust mechanical strength and consistent electrical conductivity, making it a preferred choice for many applications. However, in more specialised projects, other crimping techniques, such as Punch Crimping and Roll Crimping, may be required to suit unique requirements.

Hexagonal Crimping offers several advantages, such as broad compatibility and proven reliability. One key benefit is that it applies symmetrical pressure from all sides of the connection, reducing the risk of damaging conductors, particularly with more flexible types like Class 5 or Class 6. This method helps protect individual strands of the conductor, which can be prone to damage in other crimping techniques, such as indent crimping. However, hexagonal crimping may not be suitable for applications requiring enhanced flexibility or specific connection attributes.

Choosing the right Crimping Geometry (Crimping Shape) is crucial in optimising electrical connections. Various crimping geometries (or crimping forms) cater to different needs and offer different properties and advantages:

What are the Types of Electrical Crimping Geometry?

| CRIMPING GEOMETRY | FEATURES & BENEFITS | APPLICATIONS |

|

Hexagonal Crimping: Offers uniform compression and high tensile strength, ideal for heavy-duty applications. |

|

|

|

Indent Crimping: Provides strong mechanical stability and strength and enhances Electrical Performance & Properties. Very effective on Alu & AlCu, as it is necessary to break the oxide on Aluminium Cable to get a good electrical connection. However, it is an older method and can potentially damage the conductors if installers isn’t careful. |

|

|

|

Roll Crimping: Ensures a reliable and durable joint by rolling the metal around the wire. Compresses and secures electrical connections. |

|

|

|

Punch Crimping: Creates a highly secure connection, making it suitable for heavy-duty use. It is particularly effective when crimping Aluminium and Bimetallic terminals, where breaking through the oxide layer on the aluminium conductor is crucial to achieving a reliable electrical connection. |

|

|

|

W-Shape Crimping: Folds the material multiple times in a zigzag pattern, offering extra strength and stability to the connection. |

|

|

|

Rectangle Crimping: Provides enhanced stability and conductivity, ensuring a secure electrical connection across various applications. |

|

|

|

Square Crimping: Forms a square shape for a strong and stable connection. |

|

|

|

Oval Crimping: Creates an oval-shaped closure, ideal for confined spaces where a circular crimp isn’t possible. |

|

|

|

Trapezoid Crimping: Offers a trapezoid-shaped closure with angled edges, providing a secure connection |

|

|

|

DUAL Crimping: Creates an optimal crimp that offers exceptional protection against corrosion, mechanical stress, vibration and temperature rises, making it ideal for the toughest environments and applications. Exceeds the rigorous requirements of IEC 61238, offering outstanding resilience to high temperatures and thermal stress. |

|

E-Tech Recommends… Elpress DUAL Crimping Technology

Elpress DUAL Solution for Copper Conductors

When it comes to Elpress DUAL Technology

This innovative technology allows electrical installations to produce an optimal crimping result even in the toughest applications. DUAL technology is perfect for particularly severe conditions, where connections and joints apart from electrical and environmental properties, are also exposed to corrosion, mechanical resistance and vibrations. Among other benefits, it offers superior electrical conductivity, enhanced mechanical strength and reduced wire fatigue.

The Contact Crimping Process

The crimping sequence in Elpress solutions involves a two-stage process: first, a Hexagonal Crimp provides symmetrical contact with the conductor, ensuring the strands are fully compressed. This is followed by Indent Crimping, which enhances electrical properties by around 30% compared to conventional Hexagonal Crimping. Since the material is already compacted by the hexagonal crimp, the indent does not damage the conductor strands, maintaining both mechanical integrity and electrical performance.

Ensuring Vibration Resistance and Corrosion Protection

Electrical connections are often exposed to harsh environments, which can lead to challenges such as vibration and corrosion. Elpress DUAL Technology is designed to address these challenges. It offers enhanced Vibration Resistance and Corrosion Protection, even in the most demanding applications, such as automotive or rail industry projects.

Standards Compliance:

- Vibration resistance according to EN 50 155

- Corrosion requirements according to DIN V 40 046-37

- Mechanical strength according to SEN 24 50 10

- Crimps flexible Cu conductors according to IEC 60228, type class 5

Maximising Electrical Installations with Crimping Solutions

The reliability of electrical installations heavily depends on the integrity of crimped connections. Using Elpress DUAL Technology ensures compliance with electrical standards like IEC 60228 and BS EN 61238:1. Such adherence guarantees that electrical connections maintain the highest level of integrity, even in heavy-duty applications, including:

Elpress DUAL5 Innovation for Aluminium Conductors*

The Elpress DUAL5 Solution builds upon the DUAL concept and specifically targets highly flexible Aluminium conductors. It ensures a smooth and uniform crimp across the conductor’s entire surface, while offering optimal conductivity and durability. DUAL5 is tested according to IEC 61238-1-1: 2018 for stable conductivity under electrical load. It’s also tested for environmental stress in the form of corrosion and vibration.

Flexible aluminium conductors are inherently less resistant to mechanical stress, which makes careful handling crucial to prevent wire damage. To achieve this, crimping must be applied gently and uniformly. Additionally, an oxide layer forms quickly on the surface of the conductors, providing effective insulation. To ensure good conductivity, it’s essential to apply a forceful crimp to penetrate this oxide layer.

*Please note, the crimping geometries previously discussed in this article only refer to Elpress DUAL Technology, not the Elpress DUAL5 Solution.

System Elpress: Ensuring Integrity Through a Holistic Approach

E-Tech Components is a trusted electrical component distributor. We proudly offer Elpress Crimping Tools and solutions, renowned for their reliability and innovation.

Ultimately, the integrity of a Cable Crimping System hinges on the seamless integration of all its components: Conductor, Terminals/Lugs, Tested Tools, Documents, Trained Personnel and Service Maintenance Calibration. Remember, a Crimping System is only as strong as its weakest link. Omitting any element can lead to non-compliance, jeopardising safety and performance. At E-Tech Components, we understand that a holistic approach is essential. By ensuring that every piece of the puzzle works in harmony, this not only guarantees compliance but also delivers secure, long-lasting connections. Choosing System Elpress means committing to a comprehensive solution that prioritises quality, safety and efficiency in every installation.

Embrace the future of Crimping Technology with Elpress’s advanced solutions. Choose the reliability of our standard Crimping Geometries, or explore the cutting-edge DUAL and DUAL5 technologies. We’ll help you find the perfect fit for your project needs.

Frequently Asked Questions

Why Is Crimp Geometry So Important in Electrical Installations?

The choice of crimping geometry (crimping shape) affects the electrical conductivity, mechanical stability and overall performance of connections. This makes it crucial for ensuring reliable electrical installations.

How Do I Choose the Right Crimp Geometry for My Application?

Selecting the right crimp geometry depends on several factors, including the conductor material, insulation thickness, environmental conditions and the specific application. Equally important is the combination of the tool and lug. They must work as a system, not only being compatible with each other but also capable of producing the ideal crimp geometry for the job.

Can Crimping Geometry Impact the Durability of Electrical Connections?

Yes, different crimping shapes can enhance the durability of connections by providing better mechanical strength and reducing wire fatigue. They also improve resistance to environmental factors like corrosion and vibration.

Can I Get Free Training on Crimping and Crimping Standards?

Yes, E-Tech offers FREE training, seminars, courses and full technical support on Complete Crimping Systems, Cable Management Solutions, LV-HV Cable Joints & Terminations and other Power Cable Components. Click here to learn more.

Additional Resources

- Elpress DUAL Crimping System

- A Crimping System is No Stronger than its Weakest Link

- Crimping Standards: The Key to Safe & Reliable Connections

- Crimping: Common Mistakes & Good Practice

- Crimping Expert Paul Forester on E-Tech, Elpress and the DUAL Crimp System

Follow link for more Blog Posts on: Tooling, Crimping.

Embrace the future of crimping technology with Elpress’s advanced solutions. Whether you’re inclined towards the reliability of our standard geometries or ready to explore the cutting-edge DUAL and DUAL5 technologies, we’re here to ensure you find the perfect fit for your project needs:

FREE TECHNICAL ADVISORY SERVICE

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us about any questions, enquiries or requests you may have: +44 (0) 1744 762 929