Method of Fixing: How to Install and Use Cable Cleats

Selecting the correct cleat or fixing (cable cleat specification), is only part of the job. The power cable system designer or installer has an obligation to consider the method in which he will fix, install and fasten cables to cleats. That way he can restrain cable movement whether caused by an electrical fault or any other reason. As a rule of thumb, cleats should be firmly fastened and fixed, using supports of strength adequate to withstand forces corresponding to the values of the peak prospective short-circuit current.

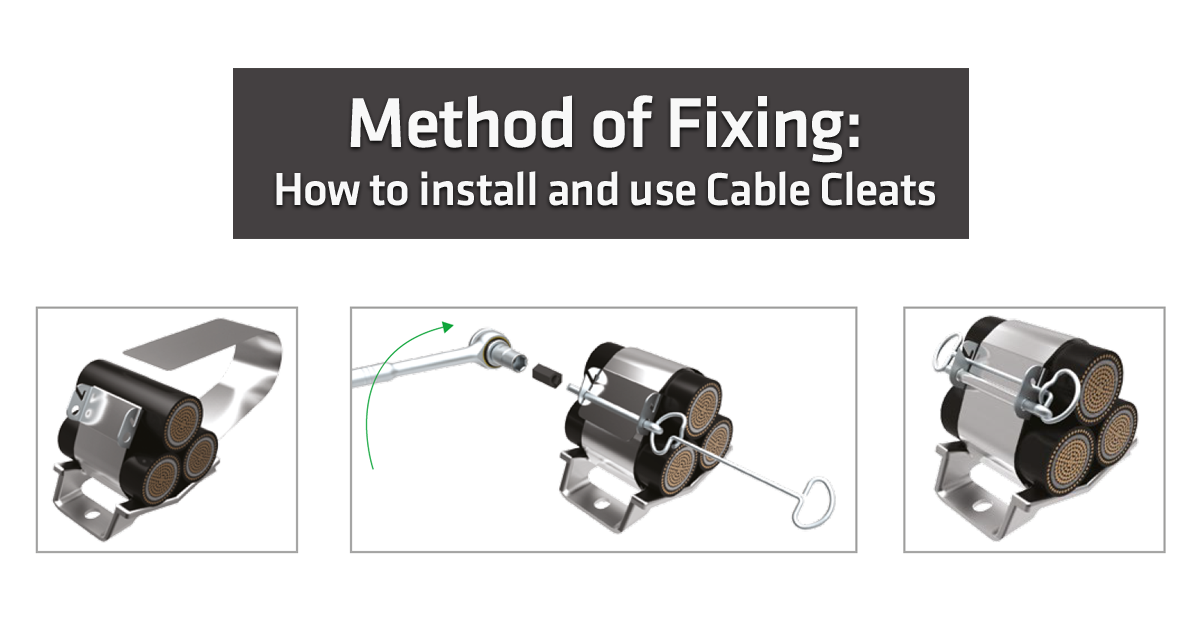

Generally, the installer will fasten cable cleats around cables by a threaded bolt and nut; the higher the torque when closing this fixing, the tighter the grip of the cleat to the cable. Having a tight grip of the cleat around the cable can be advantageous when it comes to axial slippage. Over-tightening, however, can lead to damage to both the outer sheath jacket and the construction of the cable.

Recommendation: Cleat fixings should be tightened up until the cleat is fastened around the cable tight enough to not leave any gaps between the liner of the cleat and the cable, and with no visible damage or bulging to the outer jacket.

For more information and answers to Frequently Asked Questions on Cable Clamps and Cleats (like “what are cable cleats?”, “when are cable cleats used?“, “cable cleat specification”, “correct cleat spacing” and more follow the link: What are Cable Cleats? The Definitive Guide

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us about any questions, enquiries or requests you may have: +44 (0) 1744 762 929