BS7609 & BS7727: British Standards for Crimping

Introduction: British Standards for Crimping (BS7609 & BS7727)

British Standards for Crimping set out codes of practice for installing and inspecting compression and mechanical terminals and connectors. These apply to both uninsulated and pre-insulated types used with power cables that have copper or aluminium conductors. This article explains these standards and answers the most frequently asked questions about crimping.

BS7609:1992+A2: 2009

The BS7609 Code of Practice outlines best practices for installation and inspection. It applies to uninsulated compression and mechanical connectors used with power cables that have copper (Cu) or aluminium (Al) conductors.

BS7727:1994

The BS7727 Code of Practice outlines best practices for installation and inspection. It covers pre-insulated compression terminals and connectors for cables with copper conductors up to 6mm² (10 AWG).

Crimping Systems to BS7609 & BS7727

Before discussing the British Standards for Cable Crimping, it’s important to first understand what crimping is. Crimping is a method of permanently deforming a metal Terminal around an electrical Conductor using a suitable tool and high force. This creates a secure and reliable electrical connection. Now this is clear, some remaining questions naturally pop up, such as:

-What is BS7609:1992+A2:2009?

BS7609:1992+A2:2009 is a code of practice and set of Standards for Crimping. It covers the installation and inspection of uninsulated compression and mechanical connectors used with power cables that have copper conductors of 10mm² and above, or aluminium conductors of 16mm² and above.

-What is BS7727:1994?

BS7727:1994 is a code of practice for the installation and inspection of pre-insulated compression terminals and connectors used with cables that have copper conductors up to 6mm².

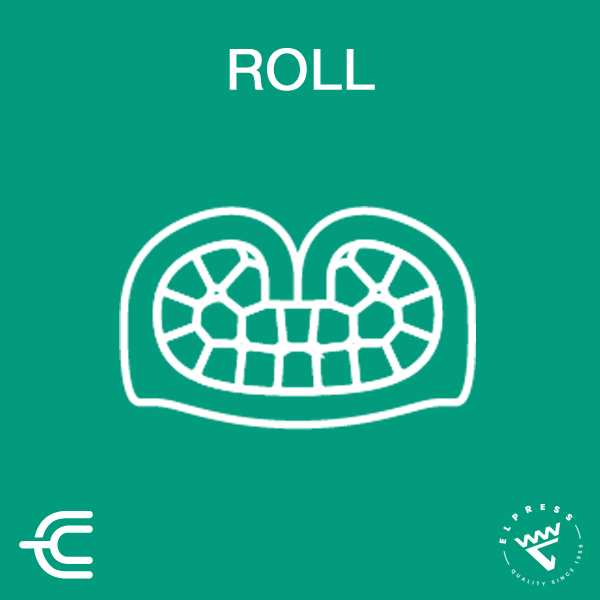

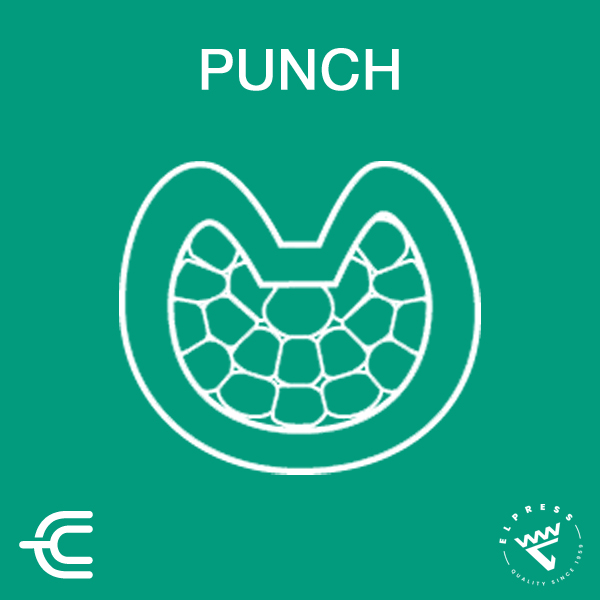

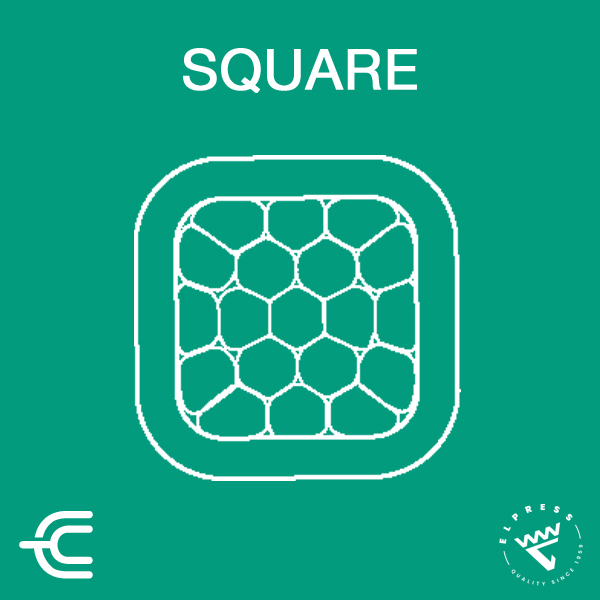

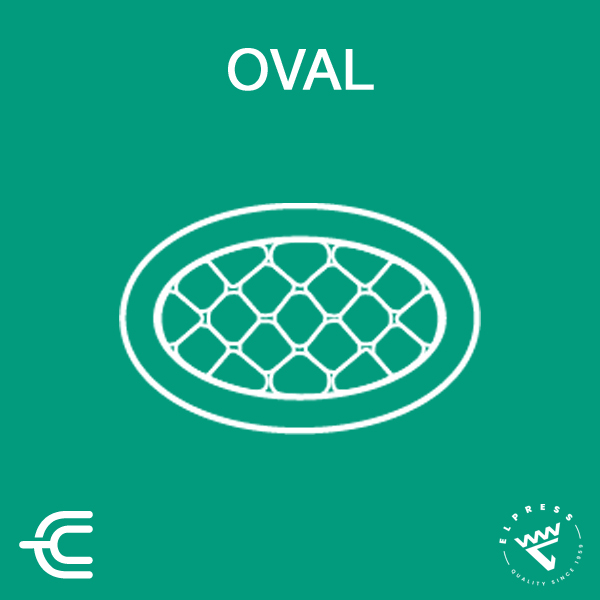

What are the Different Crimp Geometries?

Crimp geometry essentially refers to the shape, form and design of crimped electrical connections. Each geometry is suitable for certain applications and the choice influences electrical performance, mechanical strength and reliability. These are the available geometries that Elpress Crimper Tools can crimp:

|

|

|

|

|

|

|

|

|

|

Learn more about their features and benefits, as well as the applications that each of them is suitable for here:

Electrical Crimping Geometries

What are the Requirements for Connectors?

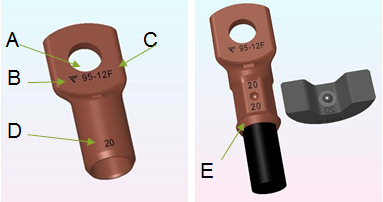

Markings:

- The reference on the barrel or palm enables you to choose the correct size and type

- It also allows you to select the correct die and tool from the manufacturer’s list

- Pay careful attention to the position of the die head on the barrel, as well as the number and order of compressions if multiple are required

- Follow proper preparation methods for both copper and aluminium conductors

A: Conductor area

B: Logotype

C: Stud size

D: Die id. -number (system identification)

E: Die number imprint

Material quality is a critical factor in connector performance. High-purity copper content and correct cross-sectional area are necessary to reduce electrical resistance and heat generation. Additionally, the thickness of the lug barrel must be appropriate to maintain mechanical strength and withstand thermal expansion. Ultimately, you should always select cable lugs from reputable manufacturers that conform to recognised standards, such as BS7609 and BS7727.

It is also essential to use a Matched Crimping System consisting of the correct cable lug, die and crimping tool specified by the manufacturer. Using matched components ensures consistent compression forces, reliable mechanical strength and optimum electrical performance. Mismatched dies or lugs can lead to poor crimps, resulting in overheating or joint failure.

Importance of Crimping Standards & Common Mistakes

– Why is complying with the British Standards (BS7609 & BS7727) so important when crimping?

Both BS7609 and BS7727 give manufacturers and contractors advice on using compression and mechanical connectors. The main aim is to make sure cables are properly terminated and that the tools used meet quality standards.

– What are some of the most common Crimping mistakes?

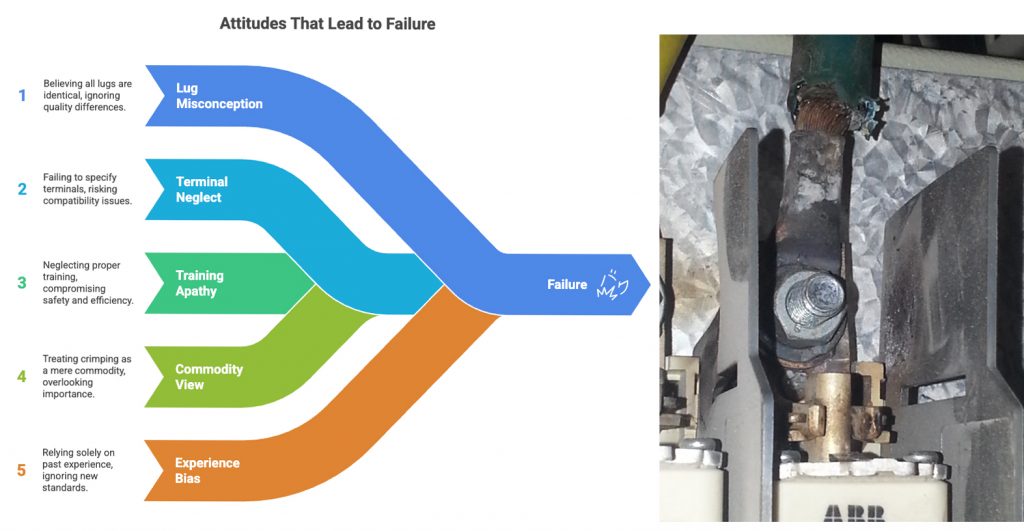

The most common Crimping mistakes stem from a lack of awareness about crimping issues and poor crimping techniques. Unfortunately, these problems are widespread across the industry. You can often spot an under-qualified installer by the phrases they use, such as:

- “A lug is a lug…”

- “They are all the same”

- “Been doing it like this for 20 years and never had a problem…”

- “Training? We can do it offshore”

- “It’s just a commodity”

- “We don’t specify terminals”

A crimping mistake is more than just a quality issue. It also involves health and safety risks, with potential fire hazards being the most serious.

Quality control checks play an important role in ensuring a reliable crimp. Visual inspections and inspection holes / windows on cable lugs make it easy to confirm a proper connection. These inspection holes allow installers to check for proper conductor insertion and compression. Routine post-crimp inspection is essential to catch errors early and maintain system reliability.

For more helpful information, follow the links below:

Crimping: Common Mistakes & Good Practice ASK E-TECH Ep. 1 | Mastering the Art of Crimping

Special Considerations for Flexible and Compacted Conductors

Certain conductor types require special attention during crimping. Extra flexible conductors with fine strands demand gentle crimping shapes to avoid strand damage. Elsewhere, compacted conductors may require higher compression forces and suitable dies to break oxide layers effectively. Always consult the manufacturer’s guidelines and use tooling designed specifically for these conductor types to ensure optimal results.

Authorised Elpress Service Centre

– What can I do if I suspect damage or a fault in my equipment?

As an Authorised Elpress Service Centre, we maintain, repair, inspect, calibrate and certify Elpress tools and power sources.

To ensure your crimped connections remain consistent and high-quality, regular checks of crimping tools are essential.

At E-Tech, we offer a full repair and calibration service for all mechanical and hydraulic crimping tools. All tools are serviced according to the manufacturer’s guidelines and in line with BS7609 and BS7727 standards.

If you suspect any damage or fault with your Elpress equipment, please contact our service department immediately on +44 (0)1744 762 929.

To return tools / products to us for: Service, Repair, Calibration, Warranty.

Click here to use the – RETURN FORM and attach it with the tool / product.

(For more information on Maintenance, Service and Calibration, click here.)

Regular calibration and maintenance of crimping tools is essential for reliable performance. Over time, tool wear or misalignment can weaken crimp quality and increase the risk of failure. Scheduled calibration ensures that your tools remain accurate and durable over time.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us about any questions, enquiries or requests you may have: +44 (0) 1744 762 929