Lightning Protection Systems and BS EN 62305: What You Need to Know

Introduction: What is a Lightning Protection System (LPS)?

Lightning strikes and electrical surges that follow them are one of the major causes of weather-related mortality worldwide. They cause hundreds of injuries in the UK every year. Furthermore, they are a huge concern for building landlords and managers since they can cause significant material and structural damages. To mitigate these risks, a Lightning Protection Risk Assessment is required to evaluate the need for protection measures based on the structure’s vulnerability. British Lightning Protection Standards, such as BS EN 62305, provide a framework for designing effective Lightning Protection Systems (LPS). These systems are a vital legal requirement your structure must meet to prevent potential injuries and damage.

Lightning Protection Systems comprise all the components, equipment and materials needed to safeguard buildings, aircraft, other structures and most importantly, people from damage and injury. These systems are used in many settings — from tall towers and skyscrapers to high-voltage power lines, stadiums and airplanes.

In addition to protecting structures, the need for lightning protection is also governed by legal frameworks. For workplaces in the UK, the Electricity at Work Regulations 1989 require employers to prevent electrical hazards — including those caused by lightning strikes and the resulting surges. This makes lightning protection risk assessments and protective measures essential.

When/ Why is Lightning Protection Required?

The purpose of a Lightning Protection System is to minimise the risk of damage to both the external and internal parts of a structure caused by a lightning strike. It does this by safely dissipating the current to the earth system. The External Protection captures the lightning current and conducts it safely to earth. The Internal Protection, with use of transient surge protectors, minimises the damage to sensitive equipment and bonding of conductive services, and ensures a safe path to earth. You can only achieve a complete LPS when you apply both internal and external safety measures to the structure based on the lightning protection risk assessment.

Risk Assessment: Determining if Lightning Protection is Needed

Buildings particularly vulnerable to lightning damage include tall structures, industrial sites, healthcare facilities, data centres, telecommunications buildings, historical landmarks and sites in storm-prone geographic areas such as coastal or elevated terrain. These require careful consideration during design to ensure the most effective protection.

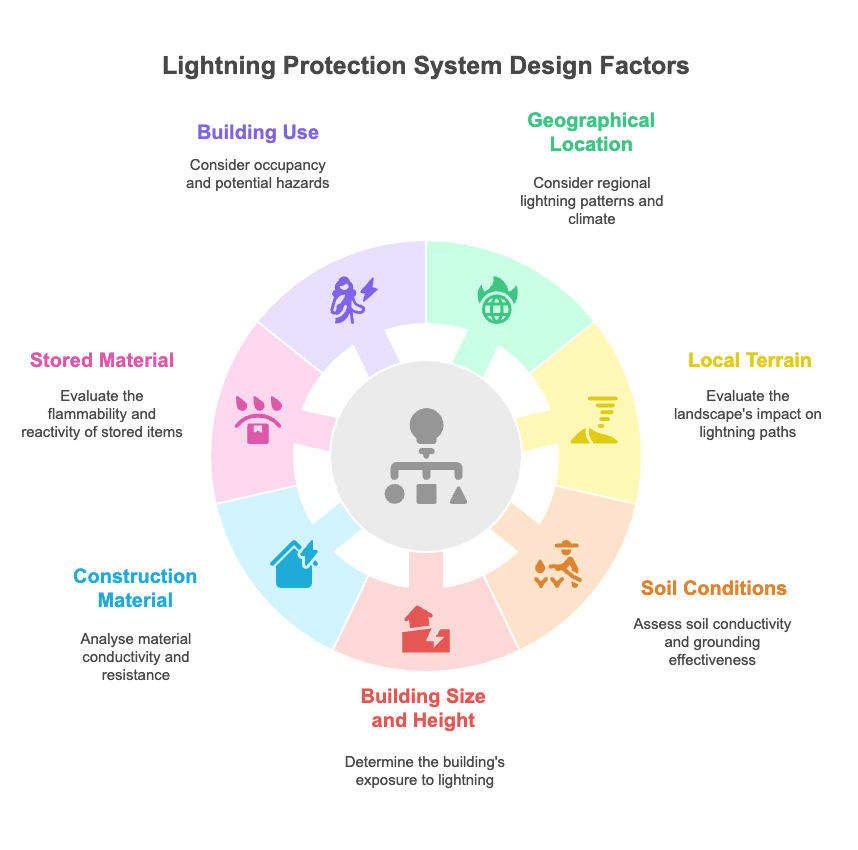

Not all buildings require a lightning protection system. However, a formal Risk Assessment is mandatory to decide whether one is necessary. This lightning risk assessment considers factors such as the building’s size, height, geographic lightning strike frequency, construction materials and occupancy. If the calculated risk is high, installing a lightning protection system is essential — not only to meet lightning protection standards but also to safeguard assets, people and operations from potential damage and costly downtime.

Basic Principles of Lightning Protection

- Capture/ Intercept the Lightning Strike (Air Termination System)

- Safely Conduct the Lightning current to Earth (Down Conductor System)

- Safely and effectively dissipate the Lightning current into the Ground (Earth Termination System)

- Provide Equipotential Bonding to prevent dangerous sparking

- Protect against the secondary effects of lightning caused by surges & transients (i.e., Surge Protection Devices (SPDs))

Surge Protection Devices (SPDs) are vital components that protect sensitive internal electrical equipment from transient overvoltages caused by lightning-induced surges. Even if the building itself is not directly struck, nearby strikes can generate powerful surges travelling along power and data lines, potentially damaging expensive and critical devices. Integrating SPDs as part of the internal lightning protection system ensures these surges are safely diverted to earth.

Lightning Protection Design Strategy

The normal strategy in achieving protection is capturing the lightning at a preferred point by the use of air terminations. Then to conduct it via low-impedance down conductors and earth electrodes to a low resistance earth of <10 Ohms (less than ten Ohms).

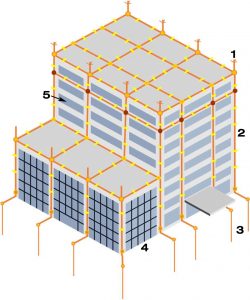

Installers space both air terminations and down conductors at regular intervals to create a mesh of conductors around the building and roof. This mesh, known as a Faraday cage, is joined together using specially produced clamps, fixings or welding.

Designing an LPS in Compliance with IEC/ BS EN 62305

The design of an LPS carefully considers many factors and follows established lightning protection standards for risk assessment. Some of these factors are:

Prior to the design of the structural Lightning Protection System, you need to carry out the Lightning Protection Risk Assessment. This happens to determine the Class of LPL required depending on IEC/ BS EN 62305 standards or internationally accepted standards. For a full list of Product Standards that AN Wallis’ solutions meet, please advise the brochure below:

Maintenance and Life of an LPS in Line with BS EN 62305

It is important to properly maintain an LPS to ensure it retains its ability to safely conduct lightning current as intended after installation. You should test and inspect earth rod resistances, conductor continuity and component integrity at least once every 12 months, in line with BS EN 62305 standards.

Corrosion, mechanical damage or degradation can increase resistance or cause faults that lead to overheating and reduced protection effectiveness. Thorough documentation of inspection results helps demonstrate compliance, identifying when maintenance or repairs are necessary. With proper care, a well-installed LPS can provide reliable protection for many years.

Compliance with BS EN 62305 and International Standards

Please use the information of this article as a general guide and not to perform designs on your own. A. N. Wallis does not accept responsibility for errors or omissions. If necessary, internationally recognised European and British lightning protection standards contain more detailed information on LPS designs for your assistance.

AN Wallis Lightning Solutions

Established in 1946, AN Wallis & Co Ltd is a world-leading manufacturer of Earthing, Lightning Protection, Exothermic Welding and Low Voltage (LV) Surge Protection products and solutions. They also offer expert design services for Earthing and Lightning Protection Systems, complying with IEC/ BS EN 62305 standards. Their Systems and Solutions minimise the risk of damage to both the external and internal parts of a structure from a lightning strike. They also reduce the risk of injuries by safely discharging the high voltage to the earth system, in line with BS EN 62305 standards.

Check the full range here View Catalogue here

Have you read our article on Earthing/ Grounding and the Elpress Deep Earthing System?

Our team is ready to answer any questions about this range or your project’s needs.

For additional information, contact us at:

sales@etechcomponents.com or +44 (0)1744 762 929