8 Common Tool Hire Mistakes & Expert Tips on How to Avoid Them

Whether you are a self-employed electrician or a contractor working on a large-scale project, there will be a time when you’ll need a specialised tool that you don’t possess. While Tool Hire or Rental offers a convenient and cost-effective solution, it’s crucial stay mindful of potential pitfalls. From selecting the wrong equipment and overlooking safety guidelines, to misunderstanding rental agreements and underestimating project timelines, countless individuals fall victim to common tool hire mistakes. This article aims to shed light on the most common errors and provide you with practical tool hire tips and solutions. By following these insights, you’ll be able to navigate the rental process smoothly, ensuring your projects are completed with safety and efficiency.

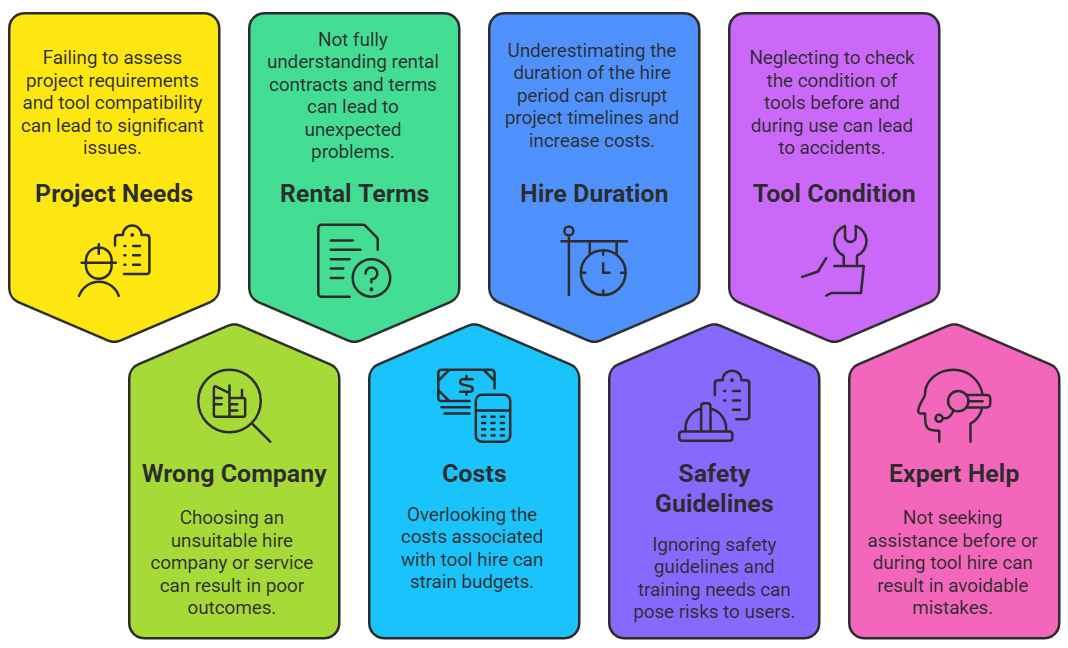

8 Common Tool Hire Mistakes

Tool hire errors aren’t just minor setbacks; they can trigger a domino effect of dangerous and costly consequences. From major project delays and unexpected expenses to compromised project quality and serious safety hazards, these mistakes can severely impact your projects, but also the safety of both yourself and those around you. Understanding the potential implications, highlights the importance of thorough planning, careful research and precise execution when hiring tools.

We have listed here the most common mistakes professionals make when hiring tools:

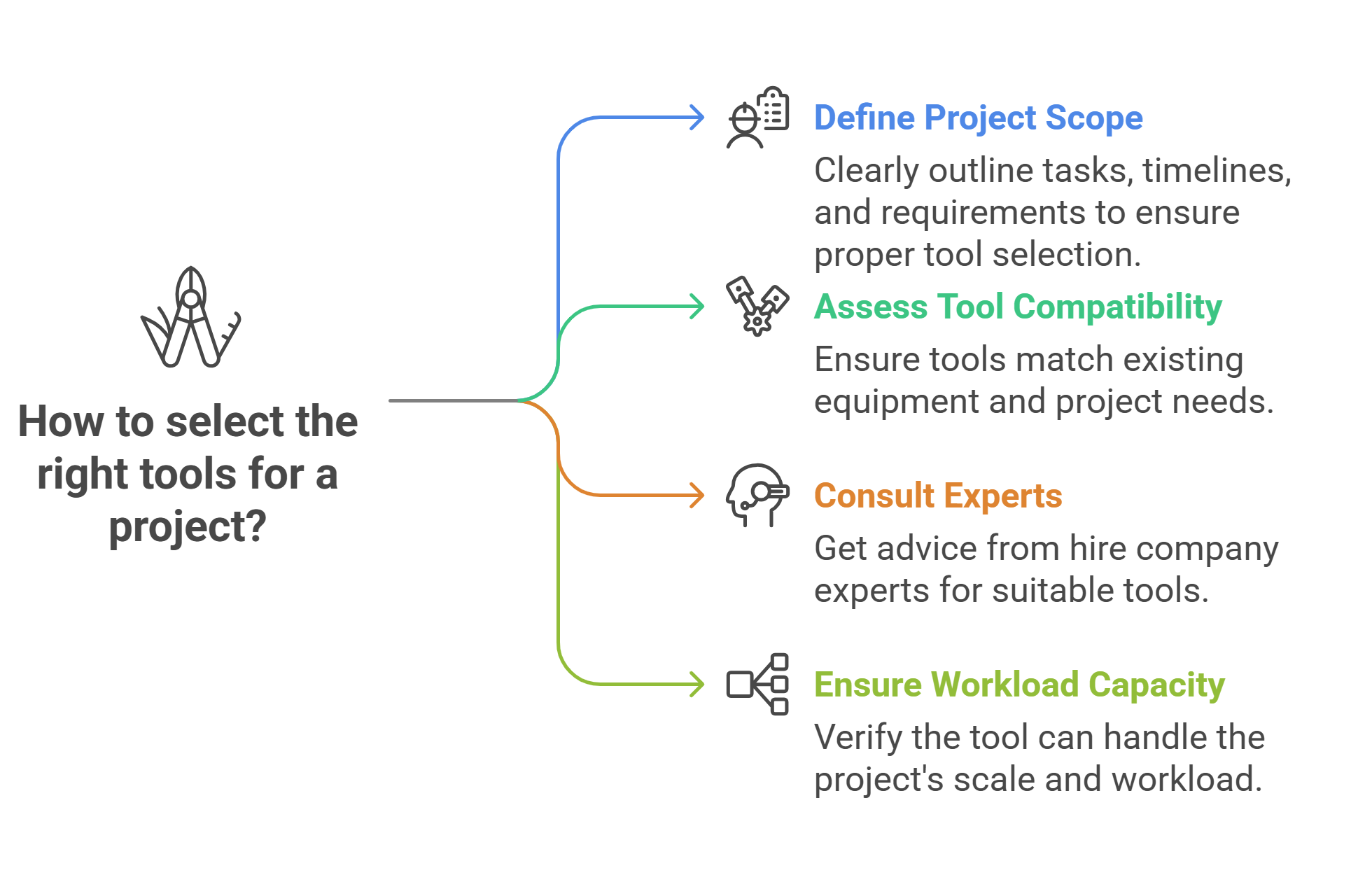

1) Failing to Assess Project Needs & Tool Compatibility Thoroughly

Successful projects rely on selecting the right equipment from the best provider – not just opting for the cheapest or the most convenient choice. The tools you choose must be suitable to the specific requirements of the project at hand. Using the wrong tool or using the right tool in the wrong way can lead to inefficiencies, safety risks, increased costs and even potential material or property damage.

Rushing into hiring tools without a comprehensive assessment of your project requirements, can result in wasted time and money. Selecting the wrong equipment or overlooking compatibility issues may cause delays, inefficiency and even safety hazards. To avoid this, you must begin by clearly defining the scope and scale of your project. What are the key tasks? What is the timeline? Are there specific conditions, such as confined spaces or challenging terrains, that could affect tool performance? How demanding is the workload?

For instance, while a simple Hand Crimper may suffice for occasional crimping applications, industrial projects often demand heavy-duty Battery-Powered Crimping Tools, Pistols or Heads with advanced features such as Display with tool data and reduced crimping time. Similarly, you should assess whether the equipment can handle the expected workload. Overloading or misusing tools beyond their capacity often leads to breakdowns, adding unnecessary downtime.

Compatibility with existing tools or systems is another critical consideration. Ensure that the hired equipment integrates seamlessly and is part of the same system with what you already have on-site and is compatible with the accessories that you intend to use. For instance, hiring a High Quality Elpress tool from E-Tech and using it to crimp unmarked, untested lugs from unknown manufacturers makes no sense. And, more importantly, it contravenes the Crimping code of practice, breaches the IEC Standards and could result in failures or catastrophic accidents! (Check out our article on Common Crimping Mistakes & Good Practices for more details on the subject.)

Finally, always seek expert advice when in doubt. Tool hire companies, like E-Tech, employ knowledgeable staff with the expertise to advise, guide and train you on the right tools for your projects. This ensures that you will make informed decisions and excellent use of your equipment.

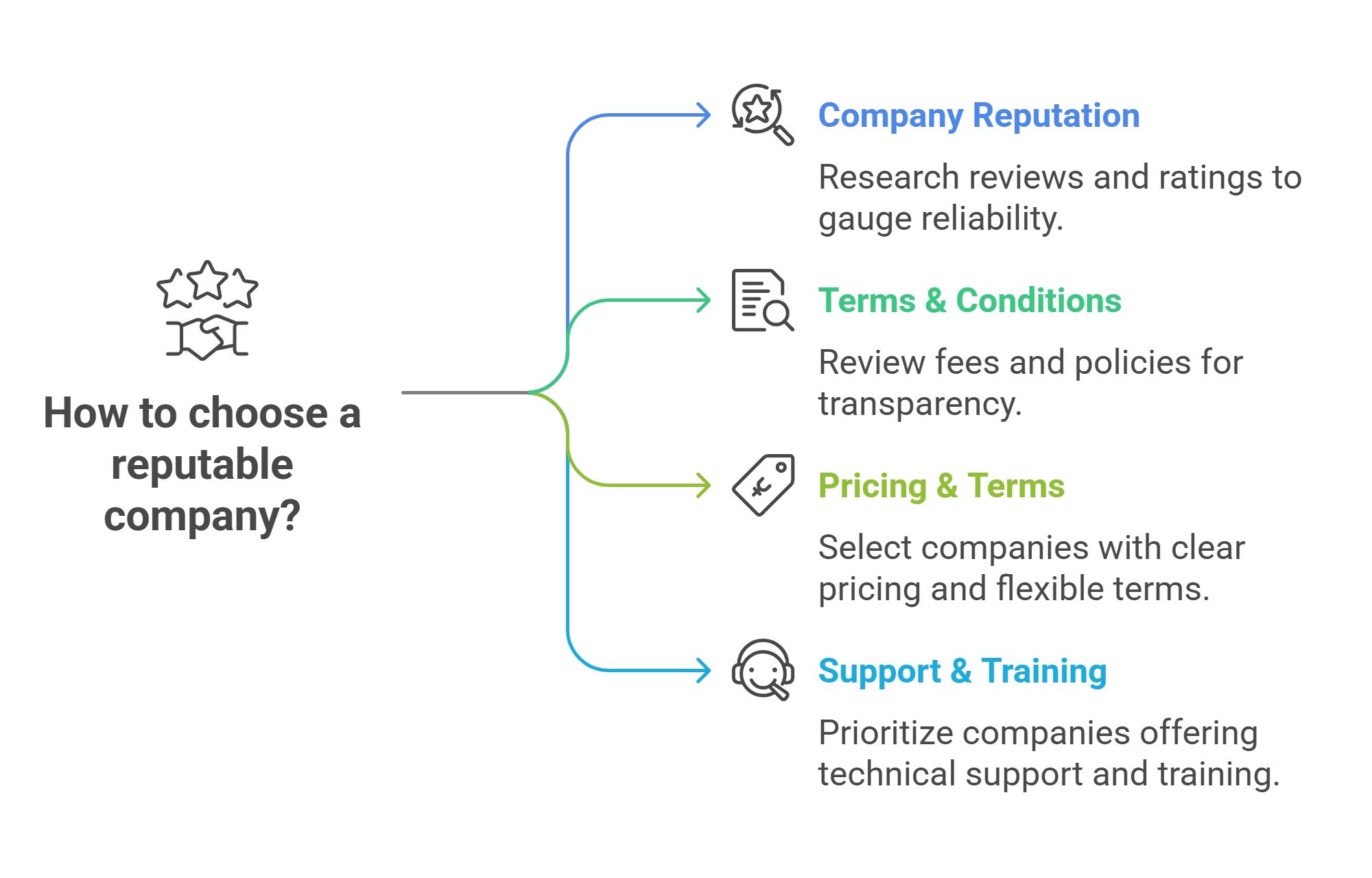

2) Choosing the Wrong Hire Company or Service

Selecting the right tool hire company or service is one of the most important steps when renting tools. A poor choice can quickly lead to unnecessary costs, project delays and even safety concerns. That’s why it’s essential to do your research in advance rather than jumping at the first or the cheapest option you come across.

A common mistake is failing to check the company you are hiring from and their reputation. Not all providers maintain their equipment to high standards, which means you might receive poorly maintained or unsafe to operate tools. Reviewing customer feedback, testimonials and independent ratings, can give you a good sense of the company’s reliability.

You also need to carefully read the terms and conditions. Hidden fees, strict late-return penalties, or unclear delivery policies can cause headaches if overlooked. Choosing a company without transparent pricing or flexible terms often leads to confusion and unnecessary disputes.

Another often-overlooked factor is technical support. Hiring from a company that doesn’t offer support or troubleshooting assistance can leave you stranded if equipment fails during the hire period. The good news? E-Tech Components offer a comprehensive Tool Support and Training Centre, including Expert Seminars, Certified Training, Tool Demonstrations, Crimping Inspection & Assessments and more.

To avoid these setbacks, you must always ask questions, read the fine print and choose a provider that aligns with your needs and budget. Taking the time to assess your options and make an informed decision, can save you from significant future frustrations.

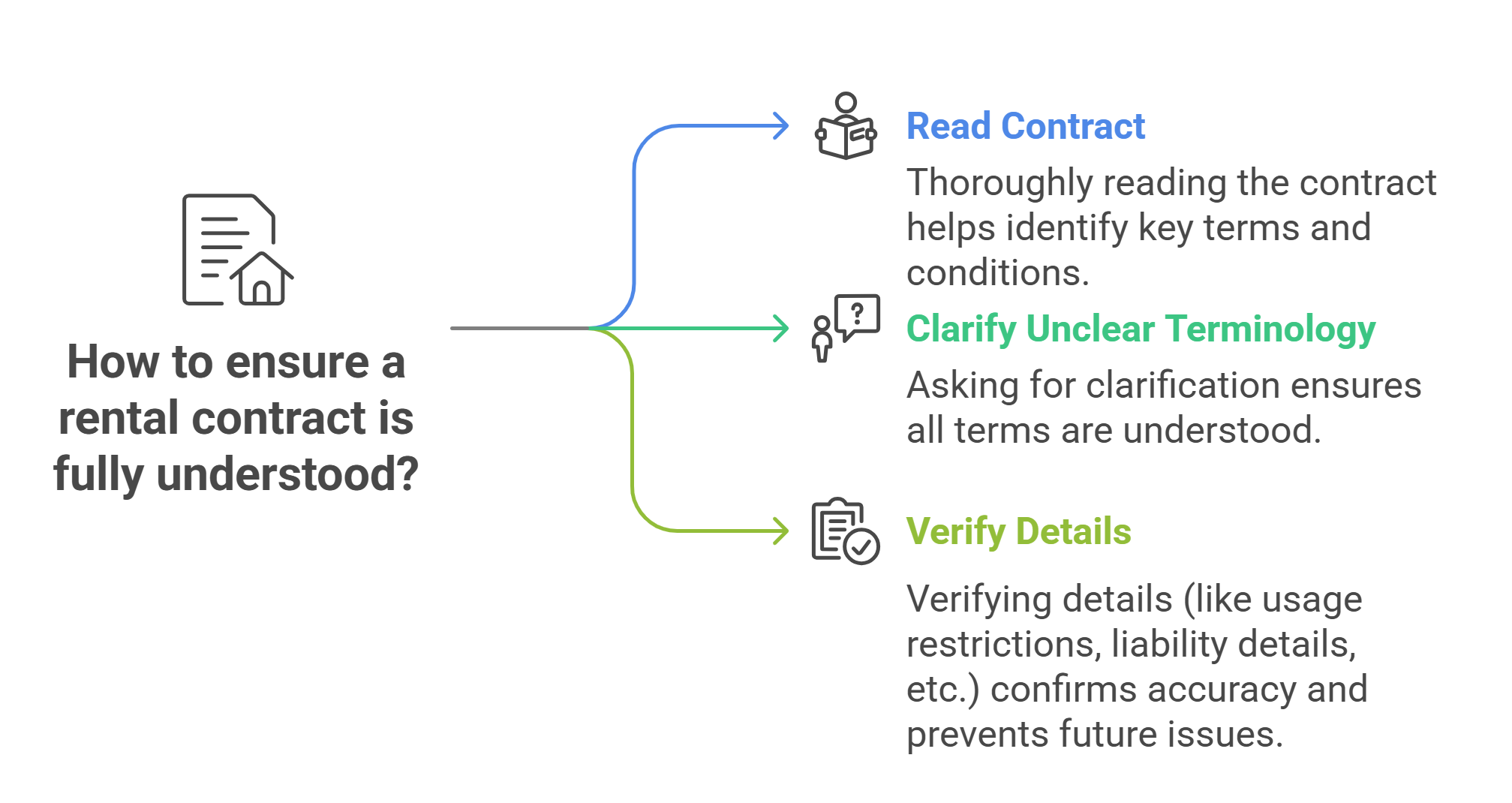

3) Not Understanding Rental Contract or Hiring Terms & Conditions

When hiring tools, it’s essential to carefully read and fully understand the rental contract and the associated terms and conditions. This step is often overlooked in the rush to get the equipment you need, leading to confusion or unexpected costs later on. Rental agreements clearly define the responsibilities of both parties, including payment schedules, maintenance expectations and return conditions.

To avoid misunderstandings, you need to confirm that the rental duration is accurate and aligns with your project timeline. Late returns can incur significant fines or penalties, so planning ahead and sticking to that plan is essential. Similarly, restrictions on usage – such as geographical limitations or prohibited operating environments – could result in breaches of the contract if you’re unaware of them. Clarifying these details upfront, ensures that you don’t inadvertently jeopardise your position in the agreement.

If you come across unclear terminology or something you don’t understand in the contract, consulting with the rental provider or seeking legal clarification is advisable. Being proactive and addressing any uncertainties early on , ensures that no issues arise during or after the hire process and protects you from potential disputes and unexpected liabilities.

4) Overlooking the Cost Implications of Tool Hire

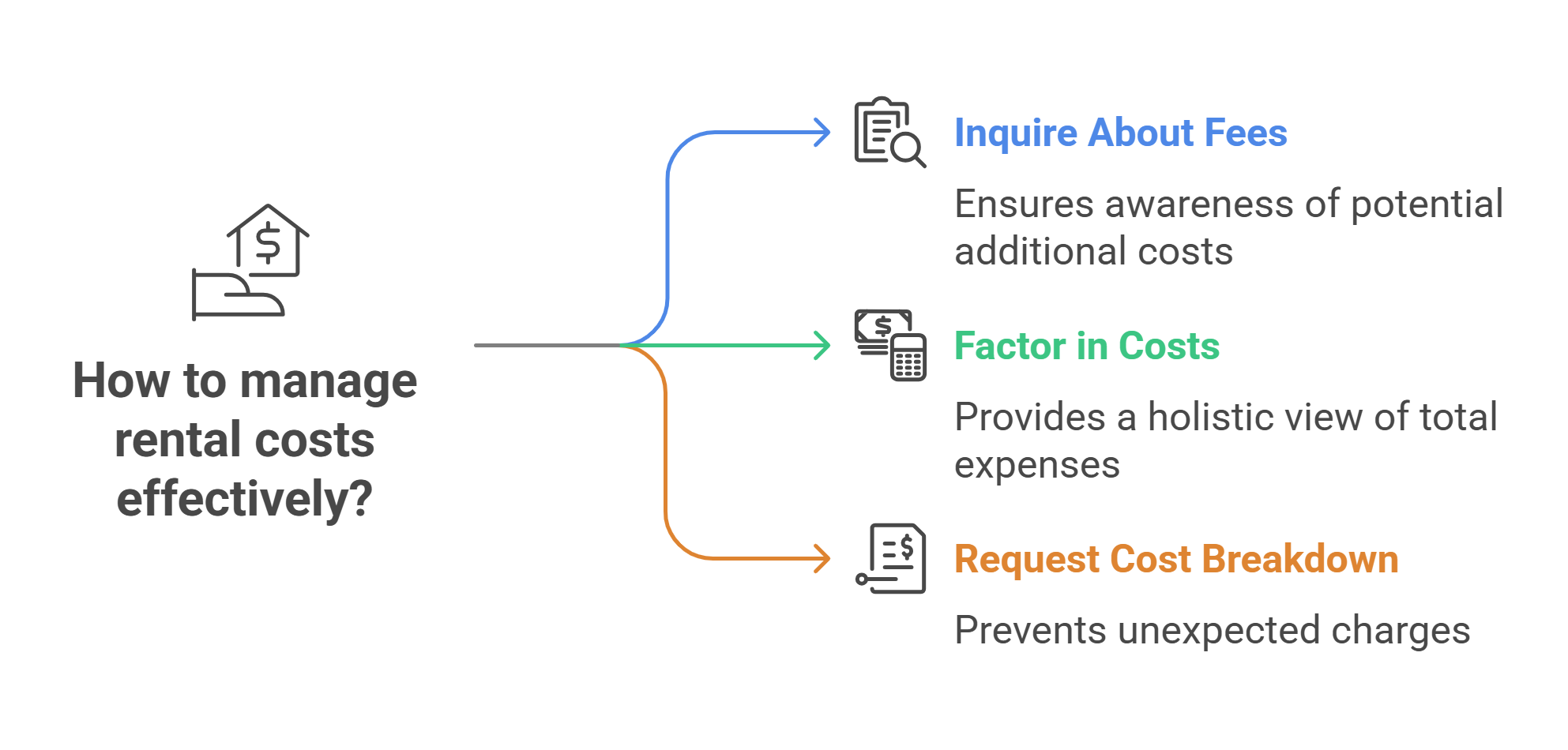

Tool hire costs often go beyond the advertised daily rates, especially if you overlook key cost factors. Unexpected expenses can quickly accumulate if you neglect to consider the full financial implications.

Key Cost Factors:

- Security Deposits: Ask about the necessary deposit. Many companies demand significant deposits, which could tie up a significant portion of funds and impact cash flow. Make sure you confirm the deposit amount in advance to avoid surprises.

- Late Return Fees: Plan realistic project timelines. Factoring potential delays and understanding extension penalties can help you avoid unnecessary fees.

- Insurance Coverage: Never assume tools are insured. Operating tools without adequate insurance can expose you to liabilities in case of damages or accidents. Always confirm insurance details and assess whether additional coverage is necessary.

- Delivery and Collection Charges: Distance impacts transport costs. Transport costs, such as mileage fees or charges for weekend deliveries, often catch customers off guard. Compare hire companies not just on tool rates but also on associated transport fees to make cost-effective decisions.

- Consumables and Accessories: Clarify what’s included. The cost of consumables like die sets or punches can add up if they’re not provided as part of the hire.

Request a comprehensive cost breakdown from the tool hire company. This will prevent unexpected charges and ensure your project stays within budget. Failing to account for these factors can lead to unnecessary financial strain.

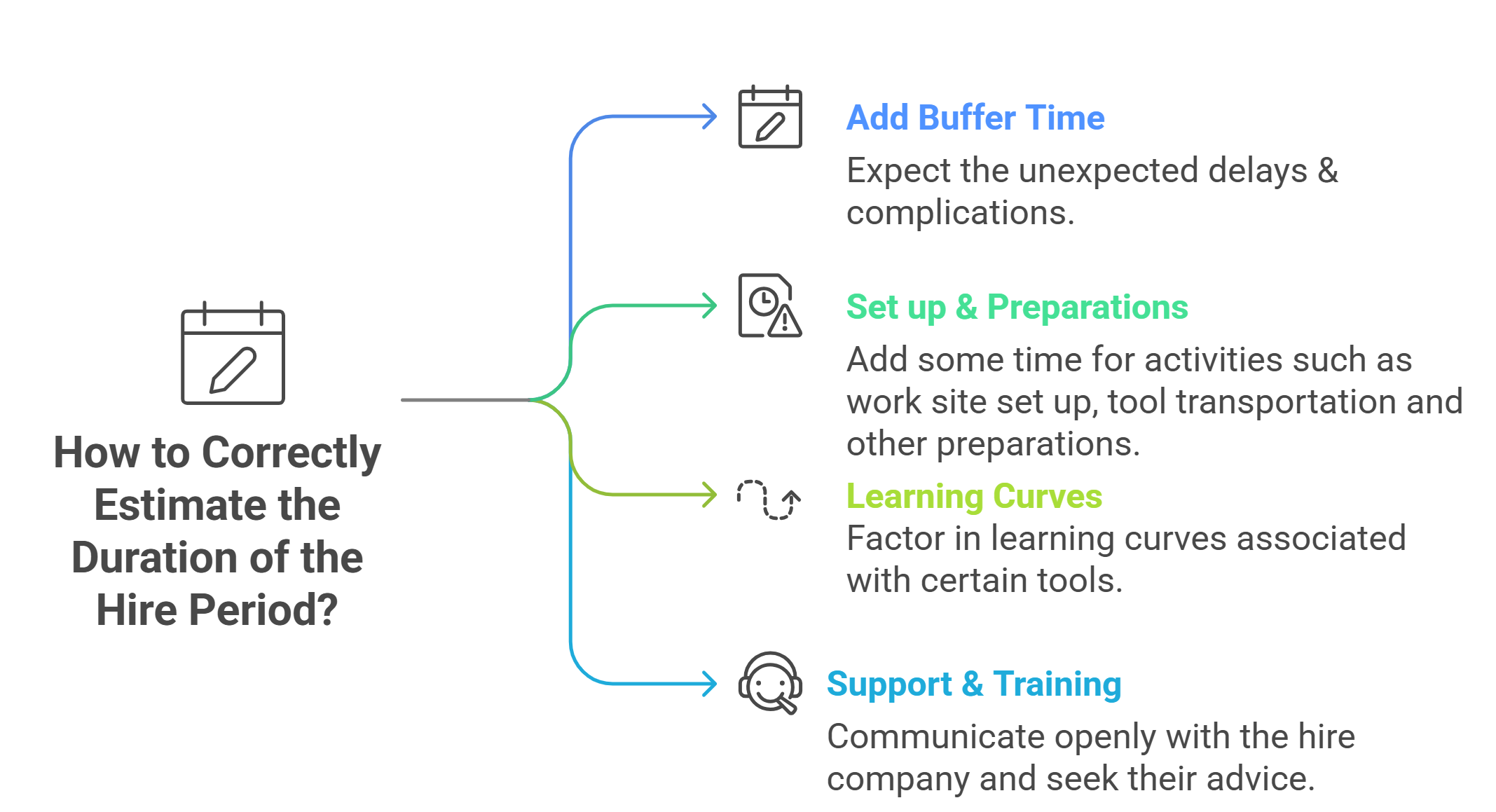

5) Underestimating the Duration of the Hire Period

When hiring tools, it’s too easy to misjudge how much time you’ll actually need them for. We often plan our projects with the ideal scenario in mind. We expect everything to run smoothly, with no delays, and all tasks taking exactly as long as we expect them to. However, reality rarely meets these expectations, leading to unnecessary stress and sometimes additional costs.

If you fail to account for unexpected delays, such as adverse weather conditions, supply chain issues, personnel shortages, power outages or even equipment malfunctions, your hire period may not be enough. This can result in last-minute extensions, which not only represent unplanned expenses but may also disrupt the availability of the tool for other users. Some hire companies also charge premium rates for short-notice extensions.

Another commonly overlooked factor is the learning curve associated with certain tools. If you are unfamiliar with a specific piece of equipment, you may require additional time to get up to speed. Additionally, complex tasks or challenging worksite conditions can extend project timelines beyond initial estimates. Setup, transportation and preparation time should also be factored into your planning.

To avoid miscalculating hire periods, you should add some buffer days (or weeks) into your schedule. Reserving equipment for an extra day or two provides flexibility for unexpected delays, helping keep your project on track. Finally, maintain open communication with the hire company and seek their advice on realistic timeframes based on your project scope and current conditions.

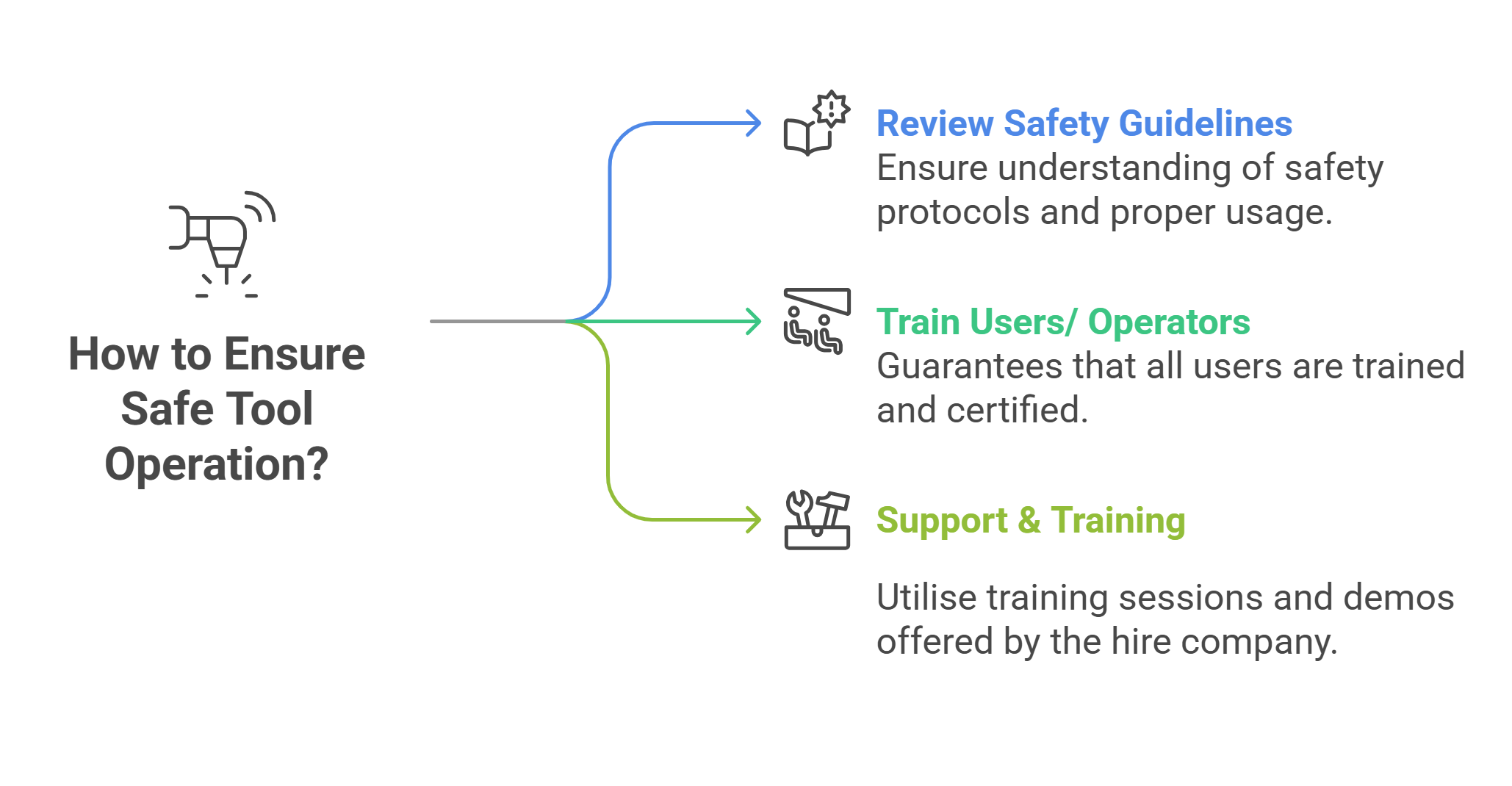

6) Ignoring Safety Guidelines & Training Needs

When you hire tools, safety isn’t just a recommendation—it’s a requirement. Ignoring established safety guidelines not only puts you at risk but also endangers those around you. While modern tools are designed with safety features, these cannot replace proper training or responsible use. Failing to address these critical aspects significantly increases the risk of accidents or damage.

One of the most common mistakes when hiring tools is operating them without fully understanding how they work. User manuals and safety guidelines are often ignored, leading to improper use. Without clear knowledge of both operation and maintenance, you may misuse the equipment, heightening the risk of injury and wear. Most rental companies provide detailed safety instructions, so take the time to review them thoroughly.

Similarly, one of the most important considerations before hiring is: are all users properly trained and certified? Lack of proper training is a major cause of tool-related errors. If operators are not adequately prepared, they put themselves – and the entire site – at unnecessary risk. Ensuring competency before work begins isn’t just best practice – it’s a fundamental safety obligation.

To minimise these risks, make sure all tool operators are fully trained and certified in safe operation. Also, ensure they always use appropriate Personal Protective Equipment (PPE), such as safety glasses, gloves and hearing protection, as required by the specific tools and tasks involved. Many rental companies offer training sessions, apprentice courses, tool demonstrations and on-site safety assessments – yet these valuable resources often go unused. By prioritising safety and training, you maintain compliance with regulations but also create a safer accountable work environment.

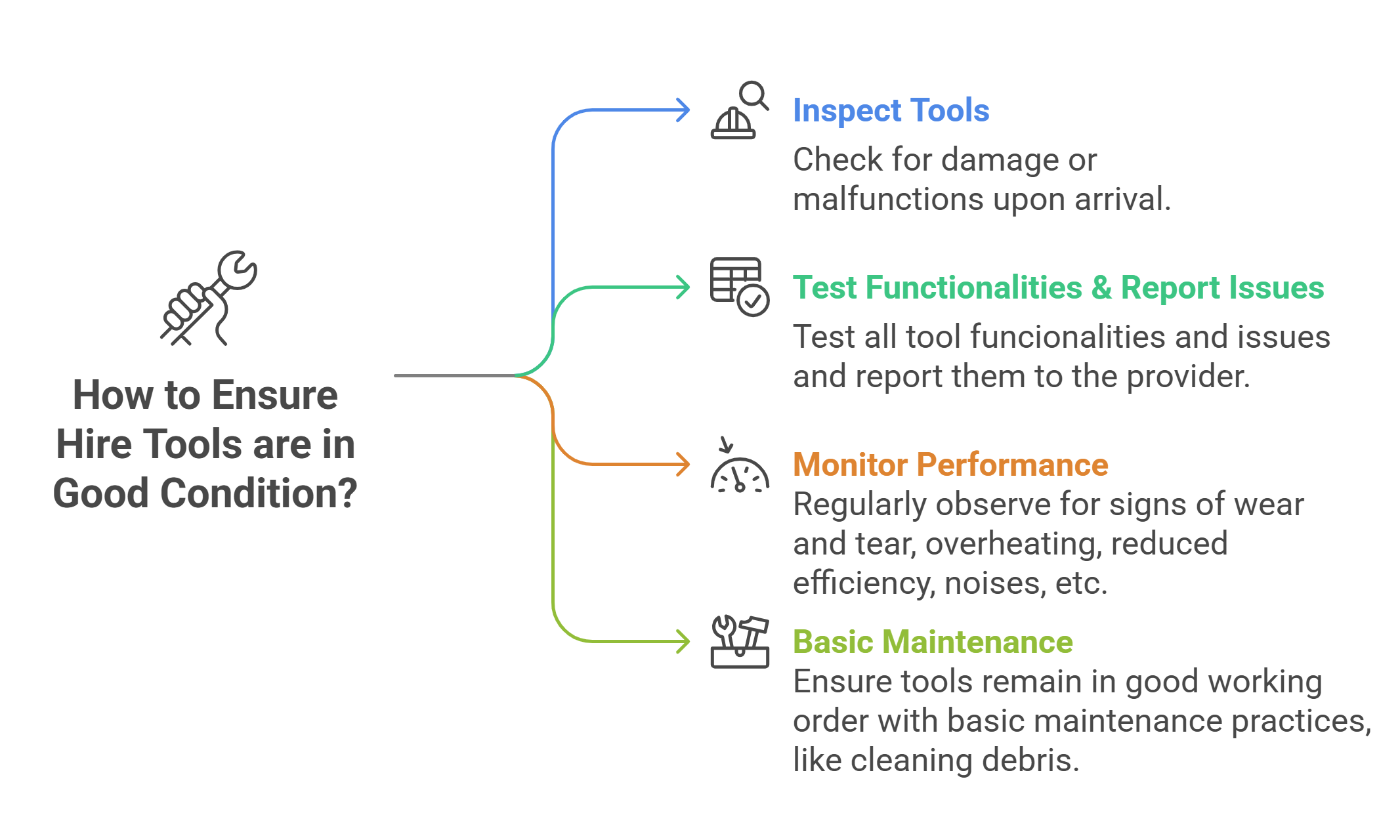

7) Neglecting to Check Tool Condition Before & While Using

When hiring tools, it’s easy to assume they’re in perfect working order. However, it’s essential to inspect them thoroughly before use and continue checking their condition throughout the hire period.

To prevent avoidable breakdowns, safety risks and costly delays, a detailed inspection is crucial when the tool arrives. This ensures you spot any pre-existing damage, preventing you from being held liable for issues you didn’t cause. Look for visible signs of damage, such as cracks, rust, loose fittings or worn components. Test key functions, including starting mechanisms, response controls and specialised features. Even minor issues can escalate into major malfunctions if ignored. Identifying problems early not only saves you time and effort later but also helps you avoid unexpected repair costs or delays due to equipment failure. Taking clear photos of the tool’s condition at both the start and end of the rental period provides a record that can help resolve any disputes.

Once the tool is in use, ongoing monitoring is just as important. Regularly check for signs of wear, such as overheating, reduced efficiency or unusual noises. Reporting these issues immediately allows for quick resolution, preventing a complete tool failure at a critical moment. Basic maintenance, such as lubricating moving parts and cleaning debris, can extend tool life and ensure safe operation. Skipping these checks jeopardises productivity and increases liability. Before using, test the equipment to confirm it’s fully operational and hasn’t developed any new issues.

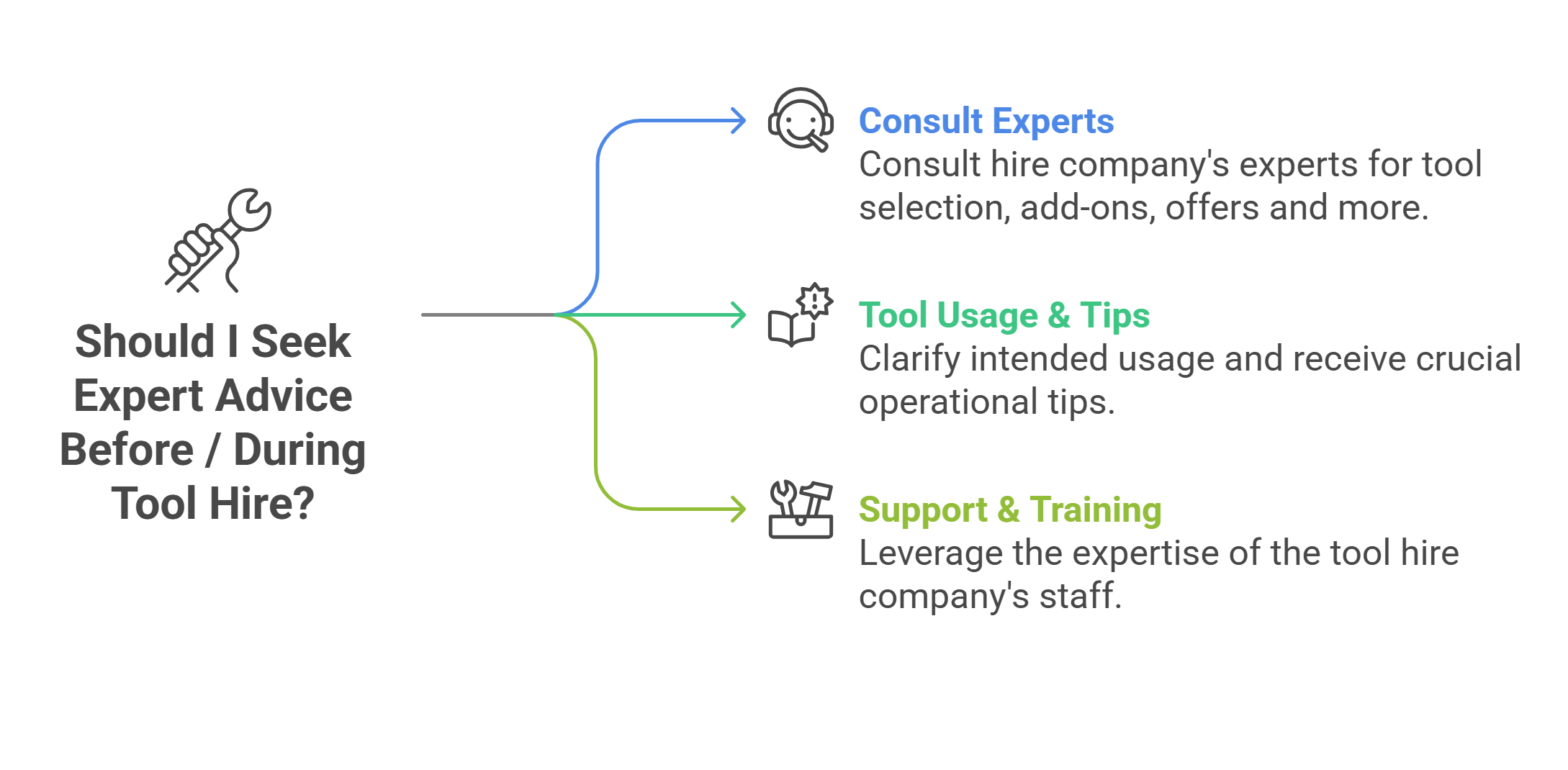

8) Not Asking for Help Before or During Tool Hire

When it comes to hiring tools, one of the most common yet costly mistakes is not seeking expert guidance – both before and during your rental period. Whether it’s due to hesitation or overconfidence, trying to navigate the process alone can lead to avoidable, time-consuming and expensive errors. Tool hire companies employ experts who can guide you toward the most suitable tool or equipment for your project, yet many people overlook this valuable resource by not asking for advice.

Without asking questions, you risk hiring tools that may not meet the technical requirements of your project. Furthermore, hiring tools without fully understanding how to operate them can compromise both safety and efficiency. Speaking with hire professionals will allow you to clarify details and receive crucial operational insights that could prevent costly mistakes or accidents.

Additionally, tool hire experts can help you identify necessary accessories, consumables or add-ons, such as Die Sets, Punches and more. Clear communication with the provider can also reveal special offers or bundled rental deals that could save you money. Remember, support isn’t just available at the start – it’s there throughout your hire period. Don’t hesitate to take advantage of the tool hire company’s expertise to ensure a smooth, efficient and successful project.

Expert Tips for a Smooth Tool Hire Experience

We understand that hiring tools can sometimes feel overwhelming, given the numerous factors to consider. However, by taking proactive measures and staying organised, you can make the process as smooth and efficient as possible.

By following these actionable tips, you can optimise your tool hire experience, minimise errors and complete your projects efficiently.