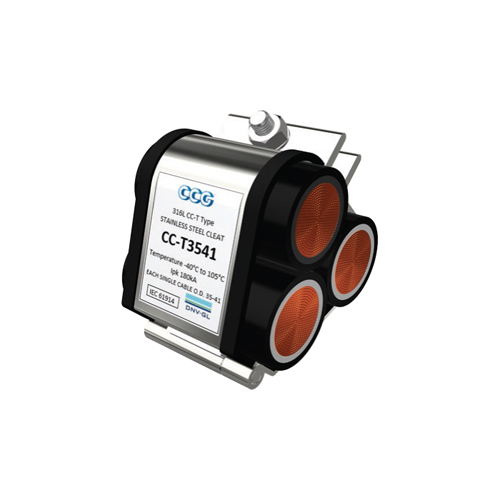

CCG Cable Terminations – Captive Component Glands

CCG Captive Component Gland commenced manufacturing cable glands and other products in 1972 using the latest German Index machining technology at the time. The launch of the original Captive Component Gland® was a direct response to a need by international mining companies. They continuously experienced problems with cable glands having loose components and incorrect installation in deep-level mines.

The concept of the CCG Cable Gland adoption by other sectors soon emerged. These included Oil, Gas and Petrochemical Industries recognising the safety advantages that it offered, especially for installation in safety-critical applications.

|

|

|

The simplicity of the “Captive Component Gland®” concept means that no matter where CCG products are installed worldwide, the simplest of instructions ensure that all parts are correctly fitted.

This concept is very important for installations and projects in developing countries where low-experience labour is the rule.

Standards & Certifications

CCG designs and manufactures all its products and is ISO 9001, ISO 14001, and ISO 45001 listed with UL USA. CCG is also quality audited by ATEX Europe, ABS USA, ITACS Australia, the IEC, and the SABS . Their products are certified to Australian, Brazilian, European, South African, and IEC standards where applicable.

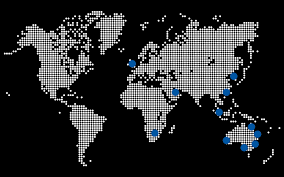

Captive Component Gland Global Presence

With our own global network of offices and warehouses in Australia, Hong Kong, Singapore, South Africa, South Korea, the United Arab Emirates and United Kingdom we are able to give an unprecedented level of service, delivery, technical advice and product training worldwide.

CCG Cable Terminations – Captive Component Glands Product Categories