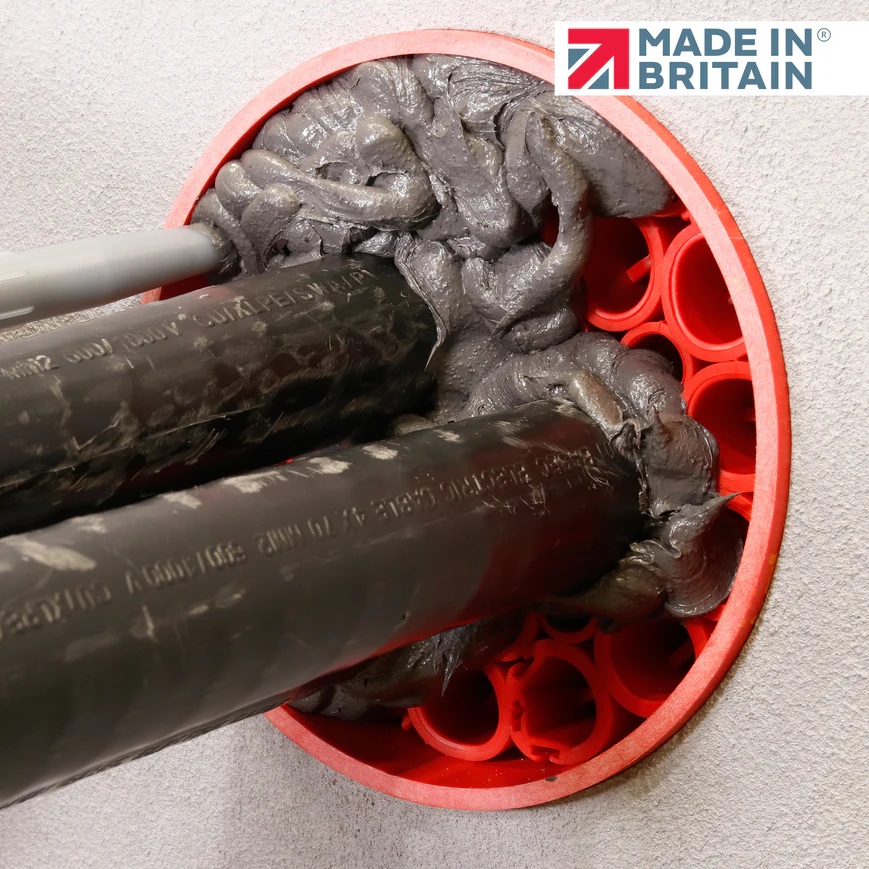

DuctSeal HG Cable Duct Sealing System

Product overview

DuctSeal HG is a re-enterable Cable Duct Sealing System designed for exceptional flexibility. It effectively seals large, heavy cables and pipes in ducted networks to protect and stop the ingress of harmful or flammable gases, liquids, smoke and pests. It has been rigorously tested to UL 94: 2013 ANSI / UL 94: 2018 standards. This duct sealing system is Network-Rail Approved (PADS No: 0086/002656).

DuctSeal HG is a re-enterable Cable Duct Sealing System designed for exceptional flexibility. It effectively seals large, heavy cables and pipes in ducted networks to protect and stop the ingress of harmful or flammable gases, liquids, smoke and pests. It has been rigorously tested to UL 94: 2013 ANSI / UL 94: 2018 standards. This duct sealing system is Network-Rail Approved (PADS No: 0086/002656).

Part Numbers: DSHG100, DSHG150, DSHG200, DSHG225, DSHG250.

DuctSeal HG Cable Duct Sealing System

DuctSeal HG Cable Duct Sealing System features a patent-pending design with a unique tubular rubber backing that can be joined into a continuous strip or formed into a ring or collar. When configured in a cross shape, it provides ideal separation for trefoil or triplex cables. This innovative design ensures DSEAR compliance and allows installers to quickly and easily achieve proper support and separation for large cables or pipes. The backing system, combined with flexible, intumescent, zero-halogen, and Zero MEKO adhesives and sealing compounds (GreyStuff or RedStuff), is designed and manufactured in the UK, ensuring exceptional quality and reliability.

DuctSeal HG Cable Duct Sealing System features a patent-pending design with a unique tubular rubber backing that can be joined into a continuous strip or formed into a ring or collar. When configured in a cross shape, it provides ideal separation for trefoil or triplex cables. This innovative design ensures DSEAR compliance and allows installers to quickly and easily achieve proper support and separation for large cables or pipes. The backing system, combined with flexible, intumescent, zero-halogen, and Zero MEKO adhesives and sealing compounds (GreyStuff or RedStuff), is designed and manufactured in the UK, ensuring exceptional quality and reliability.

Duct Seal HG System (DSHG100, DSHG150, DSHG200, DSHG225, DSHG250), along with GreyStuff or RedStuff, is a non-hazardous, superior single component, neutral curing sealant that has been specifically developed to cope with the harsh environments around duct openings to ensure ducted networks and penetrations are protected.

Key Features & Benefits

- Flame Retardant – tested to UL 94: 2013 ANSI / UL 94: 2018

- Intumescent sealant technology

- One-of-a-kind patented trefoil/triplex cable separation – The best in the market

- MEKO-free, FyBrid, Non-Hazardous Intumescent sealant

- Water & Gas Tight to 2.0 bar

- Resists Toxic Gases – Ideal for the Water Industry (Methane, Hydrogen Sulphide & Chlorine)

- Resistant to many other gases & liquids (e.g. ADBLUE & Antifreeze)

- Resists Hydrocarbons (Petrol, Diesel, ASTM oil, & LPG Gas) – Perfect for the Petrol Forecourt industry

- Microbial Resistance – coverage against Fungi, E-Coli, Escherichia coli, Staphylococcus aureus, & A. brasiliensis

- UV & Ozone resistant

- High bonding strength & Non-slumping

- Odourless when curing

- Zero Halogen

- Forms a strong porous sticky char with excellent thermal insulation properties, when exposed to fire

- DSEAR, WIMES, DCG, APEA, BLUEBOOK & ATEX Compliant

- WIMES compliant, as described in the WIMES Specification in section 3.02 2019 (clause 6.4.3.2d)

- Complies with 2011 NEC Articles 225.27, 230.8, 300.5(G), 300.7 (A) on Raceway Seals, and 501.15 (B)(2)

- Petrol station forecourt accepted, as per the technology described in the APEA Blue book – 4th Edition, 4.6.8

- ATEX Compliant – Contains no moving parts or any form of material that can create a spark

- Age tested to 50 years – Independently tested.

- MADE IN THE UK

DuctSeal HG Duct Sealing System – Order Information

| Product No. |

Description | Max Duct Opening | Unit Sold |

| DSHG100 | 1 x DuctSeal HG Kit up to 100 mm | 100 mm | x 1 Kit |

| DSHG150 | 2 x DuctSeal HG Kits up to 150 mm | 150 mm | x 2 Kits |

| DSHG200 | 3 x DuctSeal HG Kits up to 200 mm | 200 mm | x 3 Kits |

| DSHG225 | 4 x DuctSeal HG Kits up to 225 mm | 225 mm | x 4 Kits |

| DSHG250 | 5 x DuctSeal HG Kits up to 250 mm | 250 mm | x 5 Kits |

AC Cable Solutions

DuctSeal is an AC Cable Solutions’ brand. AC Cable Solutions operates as a privately owned limited company based in Trafford Park, Manchester. They specialise in high-quality Re-Enterable, Mechanical and Chemical Sealing Products for a broad range of industries. From Construction and Mining to Manufacturing, Transport, Infrastructure and Utilities, they provide bespoke Sealing Solutions that meet the highest quality standards. E-Tech Components is proud to be an authorised AC Cable Solutions distributor in the UK. We deliver their industry-leading products with a focus on innovation, reliability and performance.

For Additional Information on DuctSeal HG Cable Duct Sealing System (DSHG100, DSHG150, DSHG200, DSHG225, DSHG250), please consult PDF File or Technical Data Table below. Data Sheet includes Installation Guidelines on Cleaning, Cure Times, Re-Entry, Removal, Storage and more.

*Technical Data subject to change without notice.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Interested in this Product?

+44 (0)1744 762 929Technical Data

| Product No. | Description | Max Duct Opening | Unit Sold |

| DSHG100 | 1 x DuctSeal HG Kit up to 100 mm | 100 mm | x 1 Kit |

| DSHG150 | 2 x DuctSeal HG Kits up to 150 mm | 150 mm | x 2 Kits |

| DSHG200 | 3 x DuctSeal HG Kits up to 200 mm | 200 mm | x 3 Kits |

| DSHG225 | 4 x DuctSeal HG Kits up to 225 mm | 225 mm | x 4 Kits |

| DSHG250 | 5 x DuctSeal HG Kits up to 250 mm | 250 mm | x 5 Kits |

Performance Data

| FEATURE | MEASUREMENT |

| Density | 1.27 |

| Colour | Anthracite Grey or Brick Red |

| Skin Over Time | 10 mins |

| Curing | 3-4mm per day |

| Tack Free Time | 22 mins |

| Hardness | 35 to 38 Shore A |

| Elongation | 250% |

| Flow | 3.33 million cPs at 380°C |

| Tensile Strength | 0.72N/mm2 |

| Operating Temperature | +5 to 40°C |

| Temperature Resistance | -35 to +120°C |

| Intumescence Activation Temperature | 210°C |

| Pressure Resistance | 2.0 Bar |

| Shelf Life | 12 months |