BS7609 & BS7727: British Standards for Crimping

BS7609 & BS7727 : British Standards for Crimping are codes of practice for the installation and inspection of un-insulated and pre-insulated compression and mechanical terminals and connectors for power cables with Copper conductors or Aluminium conductors. This article aims to explain those standards and answer most Frequently Asked Questions on Crimping.

BS7609: 1992+A2: 2009

The BS7609 Code of Practice displays the best practices for installation and inspection of uninsulated compression and mechanical Connectors for power cables with Copper (Cu) or Aluminium (Al) Conductors.

BS7727: 1994

The BS7727 Code of Practice displays the best practices for installation and inspection of Pre-insulated compression Terminals and Connectors for cables with Copper conductors up to 6mm2 (10AWG).

Crimping Systems to BS7609 & BS7727

Before speaking about the British Standards for cable crimping, first we need to clarify what crimping is. Crimping is a way/ method to crimp a metal Terminal to give a permanent deformation around an electrical Conductor, to achieve good electrical connection with a suitable Tool and through high force. After clarifying the above, some essential questions pop up, like:

-What is BS7609:1992+A2:2009?

BS7609:1992+A2:2009

Code of practice and Standards for Crimping for the installation and inspection of un-insulated compression and mechanical connectors for power cables with copper conductors of 10mm² and above, or aluminium conductors of 16mm² and above.

-What is BS7727:1994?

BS7727:1994

Code of practice for the installation and inspection of pre-insulated compression terminals and connectors for cables with copper conductors up to 6mm2.

-What are the different crimp shapes and forms?

Hexagonal crimping for tube-shaped necks

|

Indent crimping

|

Punch-Matrix crimping

|

-What are the requirements for connectors?

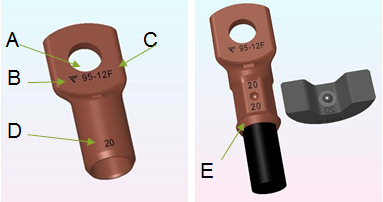

Markings:

- Reference on the barrel or palm to enable user to choose correct size and type.

- It should allow correct die and tool to be selected from manufacturers list.

- Careful attention to the position of Die Head on barrel and number and order of compressions if multiple.

- Covers preparation of copper and aluminium conductors.

A: Conductor area

B: Logotype

C: Stud size

D: Die id.-number (system identification)

E: Die number imprint

Importance of Crimping Standards & Common Mistakes

-Why complying with the British Standards (BS7609 & BS7727) is so important when crimping?

Both codes of practice (BS7609 & BS7727) intend to give guidance to manufacturers and contractors who use compression and mechanical connectors to enable cables to be terminated using good engineering practice and to provide quality control guidance for the tooling.

-What are some of the most common crimping mistakes?

The most common crimping mistakes derive from the lack of awareness of crimping issues and the application of bad crimping techniques. Unfortunately, these are widespread in all sectors of the industry and you can usually recognise an underqualified installer by the use of the following phrases:

- “A lug is a lug…”

- “They are all the same”

- “Been doing it like this for 20 years and never had a problem…”

- “Training? We can do it offshore”

- “It is just a commodity”

- “We don’t specify terminals”

A crimping mistake, apart from being a quality issue it also bears Health & Safety implications and potential fire risks. Follow the below link for an article dedicated to:

Crimping: Common Mistakes & Good Practice

Authorised Elpress Service Centre

-What can I do if I suspect damage or a fault in my equipment?

Our Authorised Elpress Service Centre maintains, repairs, checks, calibrates and certifies Elpress tools and power sources.

Our Authorised Elpress Service Centre maintains, repairs, checks, calibrates and certifies Elpress tools and power sources.

To ensure that your crimped connections maintain a high and even level of quality, regular checks of the crimping tools must be carried out.

E-Tech can offer a full repair and calibration service for all mechanical and hydraulic crimp tools. Crimp tools are repaired and calibrated to the Manufacturers guidelines and in accordance with BS7609 & BS7727.

If you suspect damage or a fault in your Elpress equipment, please contact our service department immediately for checking of necessary repair, tel: +44 (0)1744 762 929

To return tools / products to us for: Service, Repair, Calibration, Warranty.

Click here to use the – RETURN FORM and attach it with the tool / product.

(For more information on Maintenance, Service and Calibration click here.)

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us about any questions, enquiries or requests you may have: +44 (0) 1744 762 929