E-Tech Components’ Ultimate Guide to Crimping: Standards, Tools & Best Practice

The Complete Crimping Guide for Electrical Professionals

Electrical crimping is at the heart of safe, reliable and efficient installations. Whether you’re working on railways, wind turbines, telecom networks or industrial projects, every cable connection needs to meet strict standards, perform flawlessly and last for the long-term. For installers, engineers and procurement managers alike, understanding crimp quality, crimping techniques and compliance requirements is essential. This Crimping Guide brings together everything you need to know about cable crimping, from standards and tools to procedures and best practices. Once you’re done reading, you’ll be able to consistently deliver safe, high-quality connections.

What is Crimping?

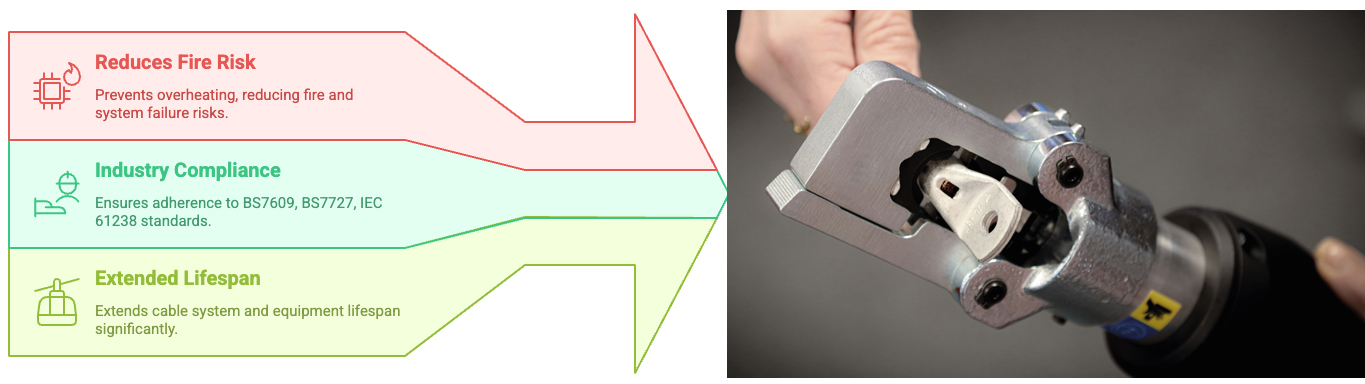

At its core, Crimping is the process of joining an electrical conductor with a terminal or connector by mechanically compressing the metal, creating a secure, low-resistance connection with strong mechanical stability. Focusing on consistency and repeatability in your crimping procedures is essential, as it can be the difference between a safe, reliable installation and a costly failure. High-quality crimps are critical for the reasons outlined below:

What is Crimp Quality?

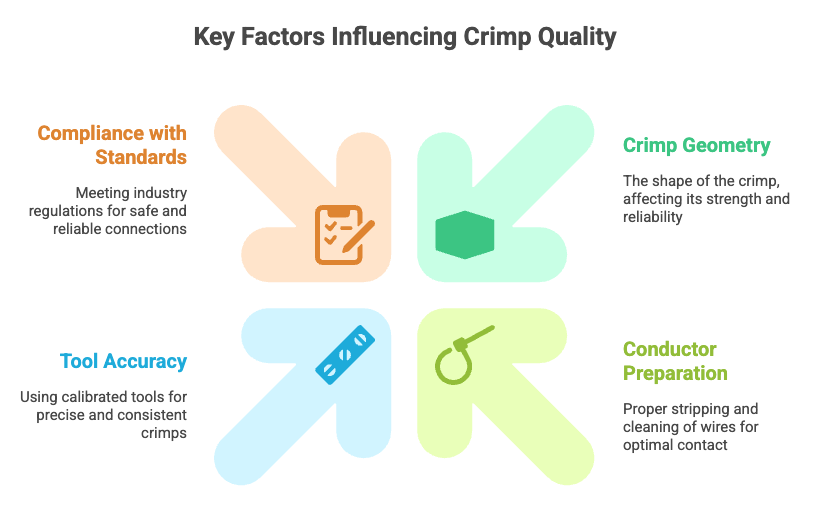

Crimp quality refers to the mechanical strength, electrical conductivity and durability of a crimped connection. High-quality crimps prevent loose connections, corrosion and mechanical failure, while also reducing the risk of high resistance, overheating and subsequent fires.

Common Crimping Techniques and How Elpress DUAL Crimping Excels

You may already be familiar with Hexagonal, Indent, and Roll Crimping, but today we recommend Elpress DUAL Crimping as the preferred technique of choice.

The Elpress Patented DUAL Crimping System / Technique sets the benchmark for demanding environments. By combining two-stage compression — first hexagonal, then indent — it delivers superior electrical performance and mechanical stability without damaging conductor strands. Completing the crimping sequence without separating the dies protects the conductor strands and preserves their original properties.

DUAL technology is perfect for particularly severe conditions, such as those experienced by trucks, wind turbines and trains. In these conditions, apart from electrical and environmental properties, connections and joints are also exposed to corrosion, mechanical resistance and vibrations.

Key Features and Benefits

- Designed for flexible Cu conductors (IEC 60228, type class 5)

- Ideal for harsh environments, providing excellent corrosion resistance, mechanical durability and vibration resistance

- Meets IEC / EN 61238:1 and offers outstanding resilience to high temperatures and thermal stress

- Meets the requirements for corrosion resistance according to DIN V 40046-37

- Meets the requirements for vibration according to EN 50155

- Meets the requirements of mechanical strength according to SEN 245010

What are Cable Crimping Standards?

Maintaining compliance is non-negotiable. By following Cable Crimping Standards and applying a robust crimping procedure, you can ensure that every crimp is safe, reliable and consistent — while protecting your business legally, operationally and financially.

Maintaining compliance is non-negotiable. By following Cable Crimping Standards and applying a robust crimping procedure, you can ensure that every crimp is safe, reliable and consistent — while protecting your business legally, operationally and financially.

-

BS7609 and BS7727 – British standards for mechanical and electrical cable terminations

-

IEC 61238 – International benchmark for compression and mechanical connectors

-

DIN V 40046-37 – Corrosion testing for harsh environmental conditions

-

EN 50155 – Vibration testing for railway applications

BS7609 & BS7727: British Standards for Crimping Cable Crimping Standards Guide

The Importance of Crimping Tool Inspection and Maintenance

Professional crimp tools are the backbone of a reliable crimping system, which is why regular crimp tool inspection and service are so important. Calibration keeps the tool’s force, alignment and geometry precise, while checks for wear and damage ensure dies, jaws and handles are replaced before they compromise quality.

Proper lubrication and cleaning reduce friction, extend tool life and keep operation smooth. Just as importantly, documenting all maintenance provides traceability and supports compliance audits. Neglecting these steps can result in poor crimps, costly delays and even regulatory breaches.

Ultimately, British installation standards BS7609 and BS7727 require that crimping tools are calibrated at least every 12 months — or every 6 months if the tool is in constant use. At the end of the day, calibration is not optional – it’s essential!

Bad Attitudes about Crimping

For more than 20 years, we’ve been championing proper crimping practices, and in that time, we’ve come across just about every careless attitude towards crimping you can imagine. The real issue lies in the fact that proper crimping training has never officially been built into the IET Wiring Regulations (BS7671), which means it often gets overlooked on site.

What should be treated as a critical safety process instead becomes an afterthought — and that mindset can have devastating consequences. The most extreme and sobering example was, of course, the Grenfell Tower fire in 2017.

As Mr. Glover, principal engineer at Failure Electrical and part of the public inquiry, reported:

And yet, despite the risks, these are still the kinds of attitudes we regularly hear in the industry:

“It’s just a bit of copper tube”

-

“A lug is a lug”

-

“They are all the same”

-

“Training? I’ve been doing it like this for 20 years”

-

“I’ve never had any problems”

-

“I’ve got a tool in my van. I’ve had it calibrated.”

-

“We’ve had a pull-off test done”

Common Crimping Mistakes to Avoid

Avoiding mistakes is a crucial part of crimping best practice and the key to achieving consistent crimp quality. Even the most experienced installers aren’t immune, and over the years we’ve seen some recurring issues crop up, including:

Crimping Mistakes & Good Practice

Correct Crimping Procedure Guide: Step-by-Step Best Practice

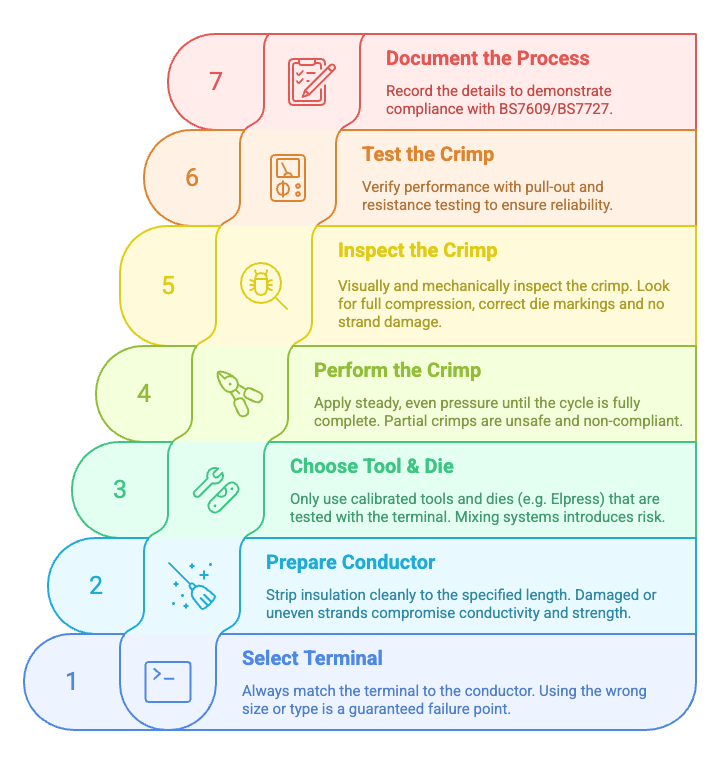

Putting crimping best practice into action helps you achieve repeatable results while staying compliant with regulations. Following a consistent procedure ensures every crimp meets the highest quality standards. Here are the key steps:

Following a strict, tested crimping procedure is more than just ticking boxes — it’s about ensuring every connection is safe, reliable and compliant. The correct use of a fully matched system — terminals, tools and dies tested together — eliminates the risks associated with mixing components that were never designed to work together. This system approach, championed by Elpress, ensures mechanical integrity, low electrical resistance and long-term durability of every crimped connection.

Historically, many installers relied on outdated standards or assumptions, believing that “a lug is a lug” or that they could freely combine terminals and tools from different suppliers. Standards like IEC61238, BS7609, and BS7727 make it clear: only use properly matched and tested systems. Failure to comply can lead to over- or under-crimped connections, increased resistance, overheating and even fire hazards. These consequences are entirely preventable when crimping best practice is followed.

Equally important is operator training. Even the highest-quality tools and terminals cannot compensate for incorrect handling. Remember — a trained operator is the most critical component of a reliable crimp. Proper training ensures that the entire crimping process (from preparation to testing and documentation) is carried out consistently, maintaining compliance, performance and safety across all installations.

By adhering to these standards and procedures, contractors and engineers protect not only their installations but also the people who rely on them. A disciplined approach to crimping minimises failures, reduces costly rework, and gives full traceability for inspections, audits and certification. This is a key differentiator in high-demand industries such as rail, industrial and utility projects.

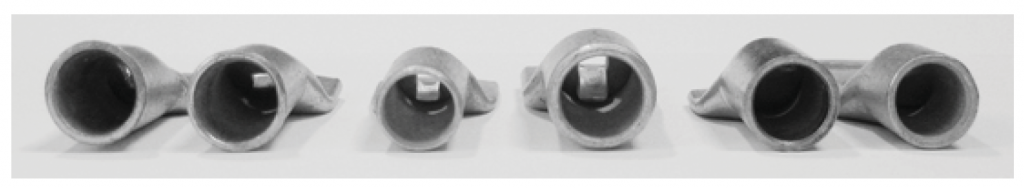

As the samples above illustrate, 95mm² lugs from different manufacturers, importers, or suppliers often vary significantly in barrel size and the amount of copper, which directly affects their current-carrying capacity. These differences mean that not all terminals can be crimped using the same tool, and attempting to do so risks serious issues such as over-crimping or under-crimping.

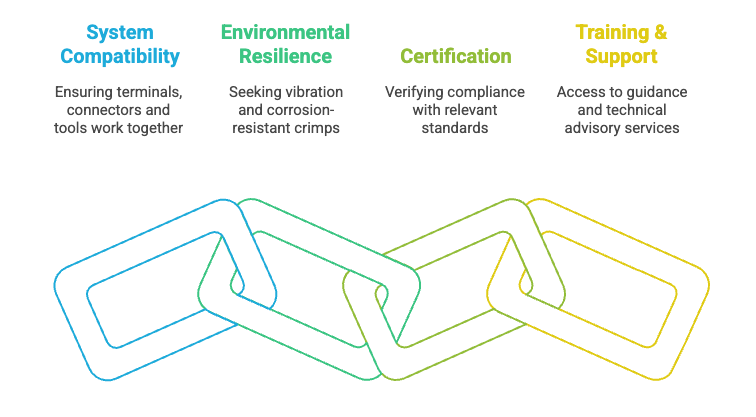

Choosing the Right Crimping System

E-Tech Components provides Elpress Crimping Systems with patented DUAL Technology, delivering a complete and reliable solution for high-demand projects. Choosing a Complete or “Matched” Crimping System is especially critical for industrial and rail applications, where performance, safety and compliance cannot be compromised.

Crimping Training and Support by E-Tech and Elpress

Crimping Training and Support by E-Tech and Elpress

E-Tech Components are dedicated to assisting and supporting our customers, ensuring they receive the highest level of service and expertise.

Knowledge, tools and compliance go hand in hand. And at the end of the day, proper training ensures that teams understand crimping techniques, standards and procedures. To help achieve consistent results, E-Tech Components provides:

-

Free technical advice and crimping best practice seminars

-

Certified training for crimping tools and systems

-

On-site inspections and compliance checks

-

Nationwide crimping tool service and calibration support

Technical Support & Training Centre

Now You’ve Read Our Crimping Guide, You Know What to Do!

A proper approach to crimping is essential for high-quality electrical installations. Understanding effective crimping techniques, following cable standards, maintaining tools and applying best practices all contribute to reliable results. By reading this Crimping Guide, you and your team can now achieve:

-

Improved crimp quality and electrical performance

-

Consistency across installations, reducing rework

-

Compliance with UK crimping regulations

-

An extended lifespan for tools and components

-

Reduced downtime and maintenance costs

Investing in quality crimping systems and procedures is more than good practice. It’s a long-term strategy for safe, efficient and dependable electrical installations.

| 📧 sales@etechcomponents.com |