Nexans Euromold Separable Connectors: Everything You Need to Know

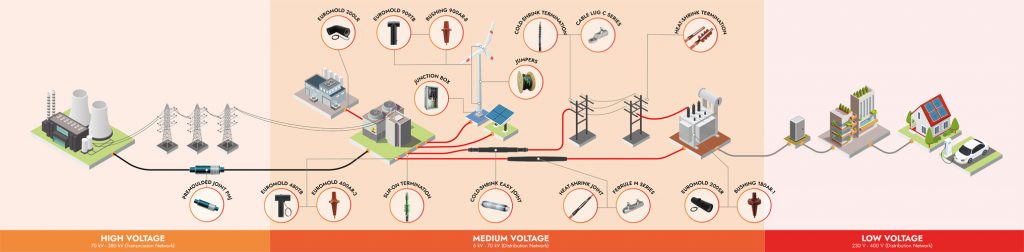

Energy infrastructure relies on cable systems that can perform under continuous stress without compromising safety or uptime. A key component in achieving this reliability is the Separable Connector. Separable Connectors (including Tee Connectors, Elbow Connectors, Straight Connectors, Coupling Connectors, and Surge Arresters) are designed to provide screened, touchproof connections between polymeric insulated cables and electrical equipment. This includes transformers and switchgear. They play a vital role in maintaining grid resilience by preventing weak points, protecting personnel and ensuring long-term performance under demanding conditions. In this article, we explore the technology (EPDM rubber), product range, benefits, applications, bushing interfaces, installation practices and future trends of Separable Connectors. We place a particular focus on Nexans Euromold Separable Connectors, which are trusted for their innovation and reliability in medium and high voltage settings.

Energy infrastructure relies on cable systems that can perform under continuous stress without compromising safety or uptime. A key component in achieving this reliability is the Separable Connector. Separable Connectors (including Tee Connectors, Elbow Connectors, Straight Connectors, Coupling Connectors, and Surge Arresters) are designed to provide screened, touchproof connections between polymeric insulated cables and electrical equipment. This includes transformers and switchgear. They play a vital role in maintaining grid resilience by preventing weak points, protecting personnel and ensuring long-term performance under demanding conditions. In this article, we explore the technology (EPDM rubber), product range, benefits, applications, bushing interfaces, installation practices and future trends of Separable Connectors. We place a particular focus on Nexans Euromold Separable Connectors, which are trusted for their innovation and reliability in medium and high voltage settings.

What are Separable Connectors?

Separable Connectors are used to connect medium and high voltage polymeric insulated cables to equipment. This includes switchgear, transformers and motors. Unlike traditional termination methods, they create a fully screened, touchproof connection that improves both safety and reliability in power distribution.

Designed for operating voltages from 6.6kV up to 72kV and higher, Separable Connectors can be installed indoors or outdoors. Their conductive EPDM outer layer provides a safe-to-touch screen. This helps to minimise electrical hazards while also making installation and maintenance more straightforward.

Another key advantage is their watertight construction. This keeps separable connectors reliable, even in submerged or harsh environments.

What are Equipment Bushings?

Equipment bushings are moulded epoxy-insulated components that form the interface between the separable connector and the electrical apparatus. Used in transformers, capacitors and switchgear, bushings withstand stress, vibration and heat while keeping electrical performance consistent.

The bushing interface provide a durable and reliable termination point, contributing to system efficiency, stability and safety. This ensures separable connectors perform effectively in demanding operational environments.

The Importance of Separable Connectors

Separable connectors do more than just connect cables to equipment — they offer several key benefits in modern MV-HV systems:

- Personnel Safety – Screened, touchproof designs protect personnel during operation

- Network Reliability – Prevents partial discharges and stops dust or water ingress, maintaining consistent system performance

- Operational Efficiency – Can be easily installed or removed when de-energised without requiring special tools

- Longevity of Service – Individually tested before leaving the plant, each connector offers a proven lifespan of 40+ years under normal conditions, with EPDM rubber inner and outer jackets providing long-lasting protection — even in harsh environments

- Compact, Flexible Design – With different shapes available for a wide range of cross-sections, they can be installed even in tight spaces

As networks shift to renewables, digitalisation and electrification, separable connectors keep systems running reliably.

Nexans Euromold: A Leader in Separable Connector Technology

Nexans Euromold is a recognised global leader in premoulded cable accessories for medium and high voltage energy distribution. As part of the Nexans Group, Euromold brings decades of expertise in rubber formulation, moulding and electrical engineering.

The company’s solutions include:

- Separable connectors (up to 72kV) that are designed to accommodate cable conductors from 16mm² to 1200mm², including round stranded, round solid, sector stranded, and class 5 flexible types in both copper and aluminium

- Bushings for switchgear and transformers up to 550kV

- Cable joints and terminations in heat shrink, cold shrink and slip-on designs

- Cable lugs and mechanical connectors for a wide range of applications

Nexans Euromold meets international standards and offers a trusted range of high-performance MV-HV cable accessories.

- CENELEC HD 629.1

- CENELEC EN 50180

- CENELEC EN 50181

- ATEX

- DNV

EPDM Rubber: The Technology Behind Separable Connectors

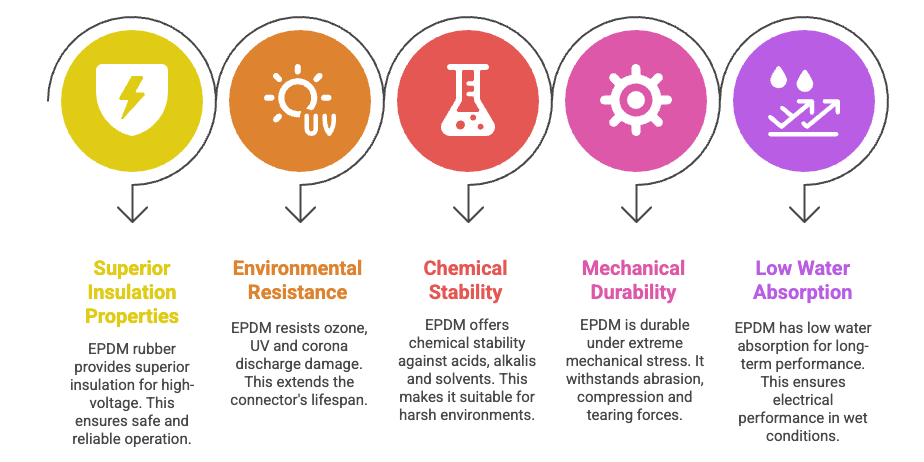

The core strength of Nexans Euromold separable connectors lies in their use of EPDM rubber. Developed and refined over 50 years, this material provides:

Compared to alternative materials such as silicone or EPR, EPDM rubber delivers a proven balance of electrical, mechanical and environmental resistance. This makes it the material of choice for long-life cable accessories.

Separable connectors prevent partial discharges, which can otherwise lead to premature insulation failure. Their premoulded EPDM rubber design ensures consistent dielectric properties and reliable electrical performance across a wide service life.

- Fully screened, touchproof construction protects personnel during operation

- Ingress protection up to IP67/IP68 ensures watertight, dustproof sealing

- ATEX-certified versions provide safe operation in explosive atmospheres

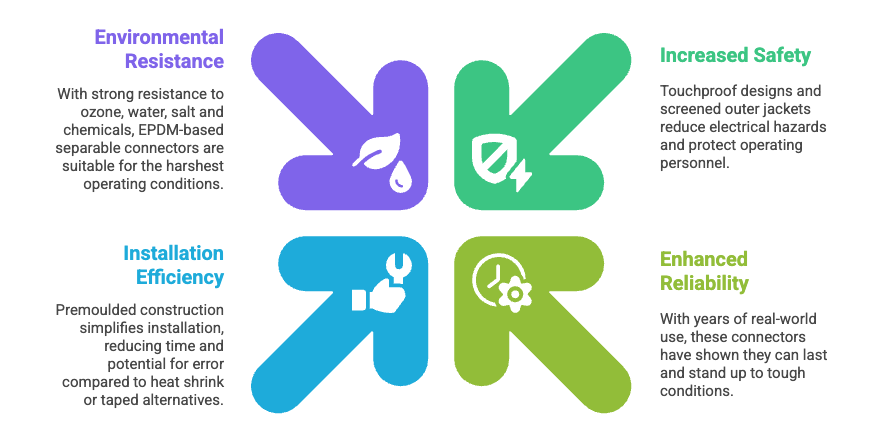

Benefits of Nexans Euromold Separable Connectors

Applications and Industries

Separable connectors appear across a wide range of industries, including:

- Power distribution – Used by utilities and grid operators to keep electricity flowing smoothly

- Renewable energy – Essential for wind farms, solar plants and offshore projects exposed to harsh conditions

- Data centres – Ensure that critical systems maintain an uninterrupted power supply

- Rail and transport – Support electrified networks and infrastructure for safe, reliable operation

- Heavy industry, mining and petrochemicals – Deliver robust performance in some of the toughest environments.

In short, wherever reliability matters most, separable connectors play a vital role in keeping systems running safely and efficiently.

Nexans Euromold Separable Connectors Made Simple: Installation, Maintenance and Best Practice

Water Sealing, IP Rating & Temperature Range

This video explains the IP rating, water sealing features and wide operating temperature range of Nexans Euromold connectors. Made from EPDM rubber, these MV-HV connectors are fully watertight. There is no ingress at the bushing interface, rear interface or cable entry. With IP67 protection and a temperature range of -40°C to +115°C (application dependent), they’re built for tough conditions.

Insulating Epoxy Plugs & Installing the Cap Interface C

This video walks you through the correct procedure, including when to use the BIPR or BIPA insulating epoxy plugs. For systems up to 24kV, the BIPR plug is used. For higher voltages, the BIPA plug includes a metallic voltage detection point and a locking mechanism that securely connects with the cap.

Bevelling the Edge of the Core Insulation During Installation

This video highlights why bevelling the edge of the core insulation is essential when installing Euromold Separable Connectors. Using the correct chamfering tool ensures a smooth, damage-free installation and helps retain silicone grease. This is essential for sliding on the connector’s cable adapter. A 45° chamfer tool works well, but for optimal results, use one that provides a smooth radius.

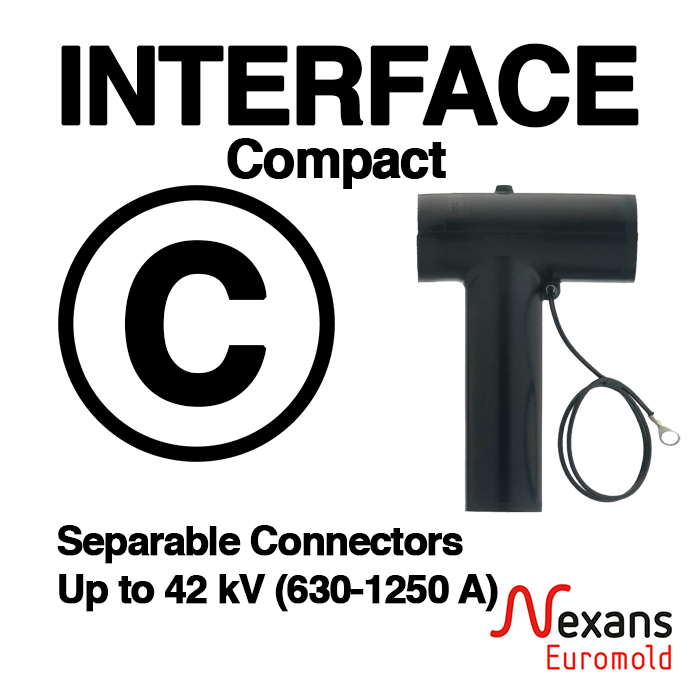

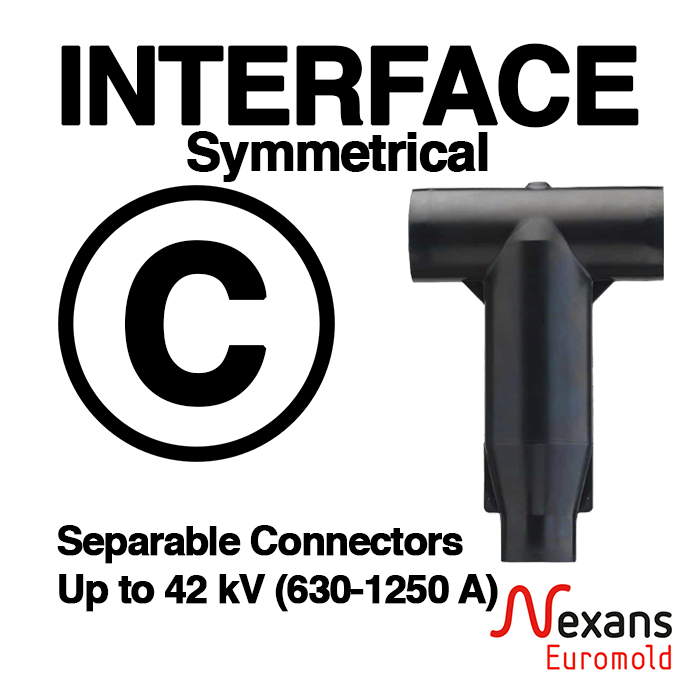

How to Install Compact Connectors

This video shows you how to correctly install Nexans Euromold Compact Connectors onto their mating bushings. Suitable for polymeric insulated cables with copper wire/tape screen, armoured or unarmoured, Nexans Euromold Interface C connectors (600 Series – C2) provide proven performance on Interface C bushings (630–1250 A).

Future Trends in Separable Connector Technology

Euromold continues to invest heavily in research and development, with ongoing innovation in EPDM rubber formulation, smart sensor integration and connector design. These advancements are aimed at extending service life, improving reliability and ensuring safer operation across demanding environments.

At an industry level, several key trends are shaping the future of separable connector technology. One of the most significant is the growing adoption of smart monitoring. Nowadays, sensors are built directly into connectors to provide real-time data on performance. Alongside this, the wider digitalisation of medium voltage networks is enabling predictive maintenance, helping operators identify and address issues before they lead to downtime. Material technology is also evolving, with enhanced compounds and sustainable alternatives being developed to boost efficiency while reducing environmental impact.

Conclusion

Separable connectors have proven themselves as safe, reliable and long-lasting solutions for medium and high-voltage cable systems. Built with Euromold’s EPDM rubber-based technology, they deliver superior performance compared to alternative materials and designs. Their versatility means they are used across a wide range of sectors, from utilities and renewable energy to transport, industry and digital infrastructure.

For tailored technical advice, specification support and the supply of high-performance Nexans separable connectors, E-Tech Components is here to help. Our expert team can guide you in selecting the right solution for your application.

E-Tech Components’ Product Range and Options

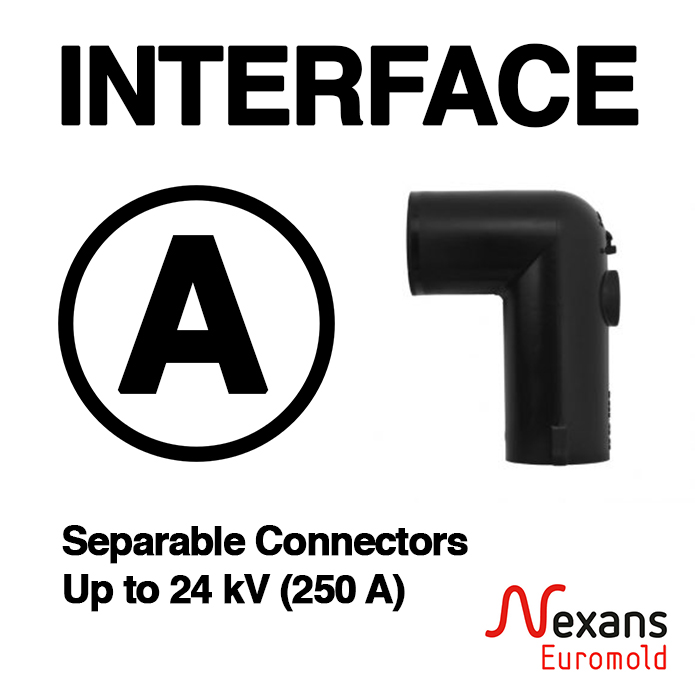

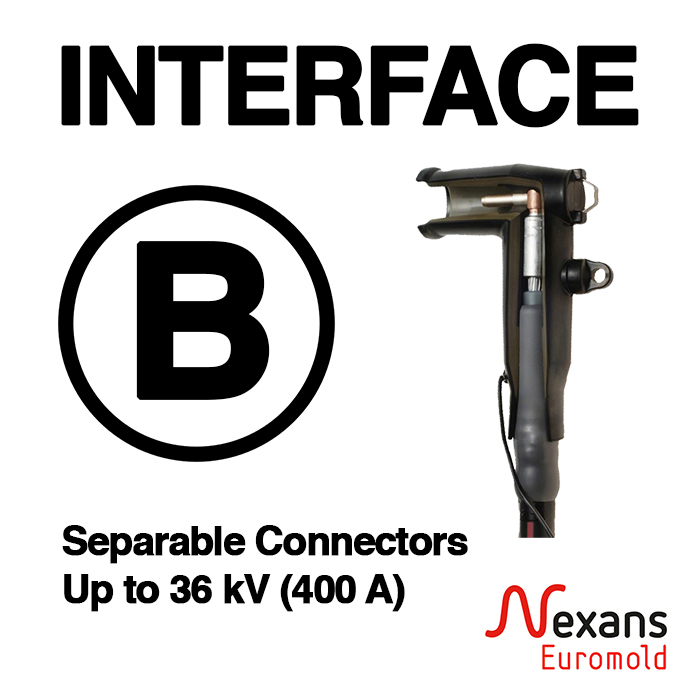

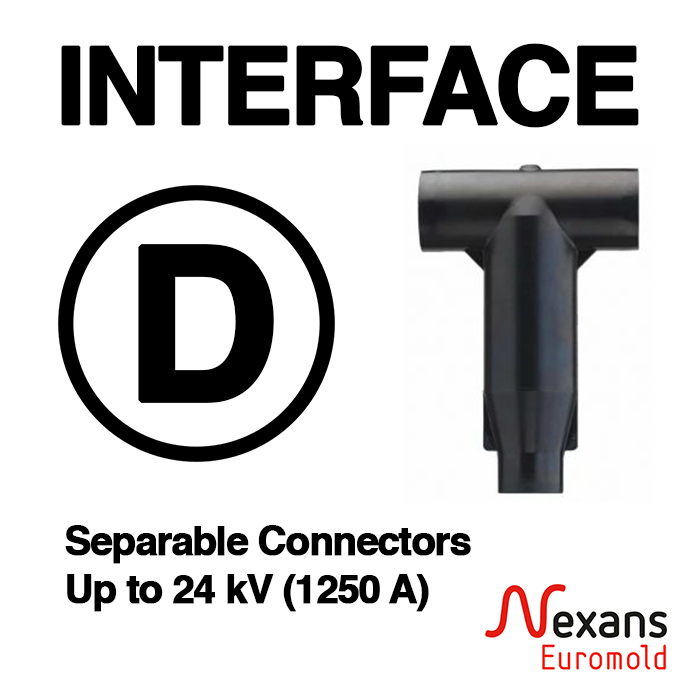

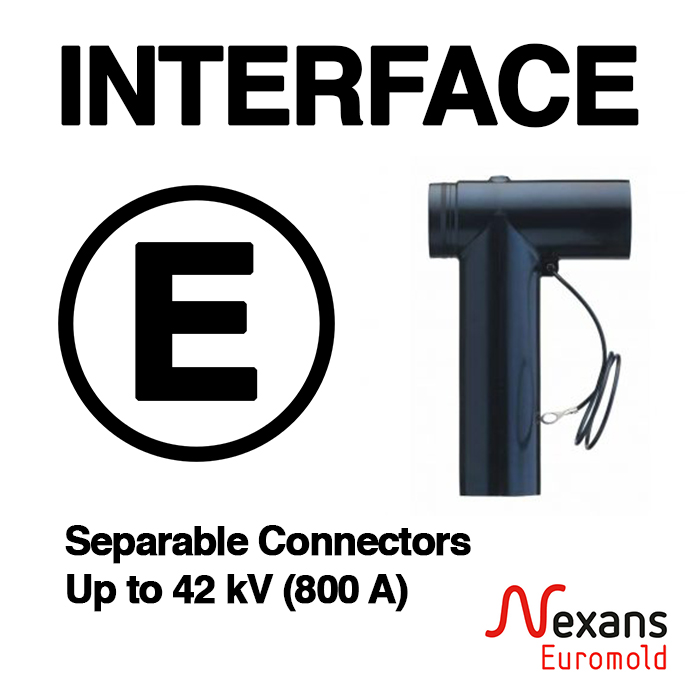

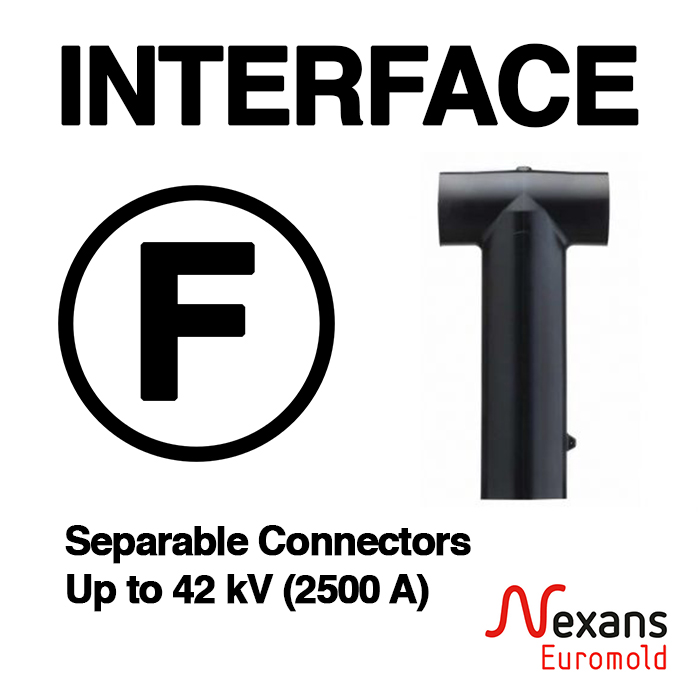

E-Tech Components is a distributor of Nexans Euromold separable connectors in the UK and abroad. Please note, these connectors come in designs for various bushing interfaces, voltage levels and cable types.

At E-Tech Components, customers can specify connector type — straight, elbow or transition — to suit the installation layout. You can also tailor connectors to match cable size and insulation type. You can add additional shielding or sealing features to enhance protection against environmental or electrical stress.

| 📞 +44 (0)1744 762 929 | 📧 sales@etechcomponents.com | Enquire Now |