AN Wallis Copperbond Earth Rods

Product overview

AN Wallis Copperbond (Copper Bonded) Earth Rods offer installers the most economical method of achieving a low earth resistance in earthing system designs.

AN Wallis Part Nos: ERB 412, ERB 415, ERB 418, ERB 424, ERB 110, ERB 112, ERB 112S, ERB 115, ERB 118, ERB 124, ERB 124S, ERB 130, ERB 200, ERB 212, ERB 215, ERB 218, ERB 224, ERB 230, ERB 324, ERB 330.

Each copperbond earth rod has a high tensile strength and low carbon steel core. 99.95% pure copper is applied electrolytically and forms a metallurgical bond between the steel core and the copper. This combination makes each earth rod ideal for deep driving whilst also providing lasting resistance to corrosion.

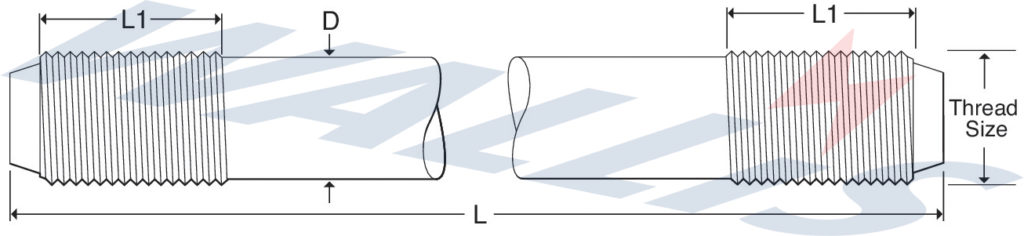

The threads on each copperbond earth rod are formed by a cold rolling process. This process ensures strength and maintains the molecularly bonded copper covering along the full length of the threads. Cold-rolled threads are stronger than cut threads.

The standard copper thickness is 0.25mm. Greater copper thicknesses are also available. Please contact our sales office for further information.

We offer a wide range of different sized Copperbond Earth Rods along with compatible threaded couplers and threaded driving heads. We also offer a quick quoting service. If you have any questions regarding any of our products, or if you require a price list please feel free to contact us.

Finally, to browse the full range of AN Wallis Earth Rods, follow the catalogue link here.

AN Wallis Copperbond Earth Rods – Technical Data

Material: 99.95% pure Copper molecularly bonded onto a steel core.

Tested: BS EN 62561-2

AN Wallis Complete Product Range

For Additional Ordering Information, Part Number Selection and other Technical Data on AN Wallis Copperbond Earth Rods (eg ERB 112, 212), please advise PDF Files below.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Interested in this Product?

+44 (0)1744 762 929Technical Data

| Part Number | Nominal Size | L | Thread Size (UNC-2A) |

Shank (D) | L1 | Unit Weight | Pack Qty |

| ERB 412 | 1/2″ | 1200 mm | 9/16″ | 12,7 mm | 30 mm | 1,18 kg | 5 |

| ERB 415 | 1/2″ | 1500 mm | 9/16″ | 12,7 mm | 30 mm | 1,18 kg | 5 |

| ERB 418 | 1/2″ | 1800 mm | 9/16″ | 12,7 mm | 30 mm | 1,76 kg | 5 |

| ERB 424 | 1/2″ | 2400 mm | 9/16″ | 12,7 mm | 30 mm | 2,36 kg | 5 |

| ERB 110 | 5/8″ | 1000 mm | 5/8″ | 14,2 mm | 30 mm | 1,28 kg | 5 |

| ERB 112 | 5/8″ | 1200 mm | 5/8″ | 14,2 mm | 30 mm | 1,53 kg | 5 |

| ERB 112S | 5/8″ | 1200 mm | 5/8″ | 14,2 mm | 40 mm | 1,53 kg | 5 |

| ERB 115 | 5/8″ | 1500 mm | 5/8″ | 14,2 mm | 30 mm | 1,95 kg | 5 |

| ERB 118 | 5/8″ | 1800 mm | 5/8″ | 14,2 mm | 30 mm | 2,23 kg | 5 |

| ERB 124 | 5/8″ | 2400 mm | 5/8″ | 14,2 mm | 30 mm | 3 kg | 5 |

| ERB 124S | 5/8″ | 2400 mm | 5/8″ | 14,2 mm | 40 mm | 3 kg | 5 |

| ERB 130 | 5/8″ | 3000 mm | 5/8″ | 14,2 mm | 30 mm | 3,7 kg | 5 |

| ERB 200 | 3/4″ | 1000 mm | 3/4″ | 17,2 mm | 35 mm | 1,65 kg | 5 |

| ERB 212 | 3/4″ | 1200 mm | 3/4″ | 17,2 mm | 35 mm | 2,2 kg | 5 |

| ERB 215 | 3/4″ | 1500 mm | 3/4″ | 17,2 mm | 35 mm | 2,76 kg | 5 |

| ERB 218 | 3/4″ | 1800 mm | 3/4″ | 17,2 mm | 35 mm | 3,26 kg | 5 |

| ERB 224 | 3/4″ | 2400 mm | 3/4″ | 17,2 mm | 35 mm | 4,45 kg | 5 |

| ERB 230 | 3/4″ | 3000 mm | 3/4″ | 17,2 mm | 35 mm | 5,48 kg | 5 |

| ERB 324 | 1″ | 2400 mm | 1″ | 23 mm | 50 mm | 2,43 kg | 5 |

| ERB 330 | 1″ | 3000 mm | 1″ | 23 mm | 50 mm | 3,04 kg | 5 |

|