CCG D1W Captive Component Cable Gland (0520)

Product overview

CCG D1W Captive Component Cable Gland

CCG D1W Captive Component Gland is an Industrial Cable Gland Device with sealing on inner sheath, used to connect and secure Steel Wire Armoured (SWA) and Aluminium Armoured Cable to major equipment. For indoor and outdoor use when fitted with a shroud.

CCG D1W Part Numbers: 052000-16, 052000, 0520-0, 052001, 052002, 052003, 052004, 052005, 052006, 052007, 052008, 052009, 052010, 052011, 052012, 052013

Features & Benefits

- For indoor and outdoor use when fitted with a shroud.

- Two-piece handling, no loose parts.

- Freely rotating captive cone and inspectable cone ring, providing an armour clamp and earth bond without twisting the armour wire.

- Factory fitted captive elastomeric inner seal for ingress protection IP66/68.

- Seals on the inner sheath of the cable.

- Precision manufactured from high-quality brass (nickel plated) available in aluminium on request.

- Complete with thread sealing gasket and heavy duty locknut.

CCG D1W Technical Data

Type: D1W Industrial Gland

Gland Material: Brass (Nickel Plated) BS 2874, EN 12164, Aluminium ASTM B221

Seal Material: Thermoset Elastomer or Silicone on request

Cable Type: Steel Wire Armour and Aluminium Armour Wire

Armour Clamping: Rotating Captive Cone and Inspectable Cone Ring

Sealing Area: Inner Sheath

Optional Accessories: Adaptor, Reducer, Earth Tag, Locknut, Serrated Washer and Shroud

Installation Standards

- AS/NZS 3000

- BS 6121-5

- BS 7671

- BS 7430

- IEC 60364-5-54

- SANS 0142

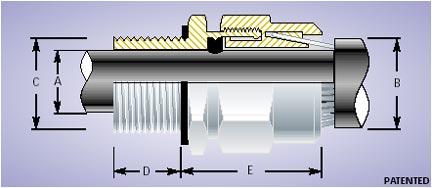

Additional Technical Data of CCG D1W Captive Component Cable Gland part numbers can be found on the table below. For Standards, Certifications & Fitting Instructions, please advise PDF Files.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Interested in this Product?

+44 (0)1744 762 929Technical Data

| Product Code | Gland Size Ref. | Metric Entry Thread (C) | Metric Entry Thread (Min D) | NPT Entry Thread (C) | NPT Entry Thread (Min D) | Cable Detail (Min A) | Cable Detail (Max A) | Cable Detail (Max B) | Max Length (E) | Armour Dia (Min F) |

Armour Dia (Max F) |

Hexagonal Detail (Max Flats) |

Hexagonal Detail (Max Crns) |

Installation Torque Value (Nm) |

| 052000-16 | 00-16ss | M16 x 1.5 | 10 | - | - | 3.0 | 8.5 | 13.5 | 32.0 | 0.90 | 0.90 | ♠♥ 24 | ♥ 27 | 35.0 |

| 052000 | 00-20ss | M20 x 1.5 | 10 | ½ | 15 | 3.0 | 8.5 | 13.5 | 32.0 | 0.90 | 0.90 | ♠♥ 24 | ♥ 27 | 35.0 |

| 0520-0 | 0-20s | M20 x 1.5 | 10 | ½ | 15 | 8.0 | 12.0 | 16.0 | 32.0 | 0.90 | 1.25 | ♠♥ 24 | ♥ 27 | 35.0 |

| 052001 | 1-20 | M20 x 1.5 | 10 | ½/¾ | 15 | 11.5 | 15.0 | 20.5 | 32.0 | 0.90 | 1.25 | ♠ 27 | 30 | 35.0 |

| 052002 | 2-25 | M25 x 1.5 | 10 | ¾/1 | 15/19 | 15.0 | 20.0 | 26.5 | 35.0 | 1.25 | 1.60 | ♠ 35 | 39 | 50.0 |

| 052003 | 3-32 | M32 x 1.5 | 10 | 1/1¼ | 19 | 20.0 | 26.5 | 33.5 | 35.0 | 1.60 | 2.00 | ♠ 42 | 47 | 70.0 |

| 052004 | 4-40 | M40 x 1.5 | 15 | 1¼/1½ | 19/21 | 26.0 | 34.0 | 42.5 | 50.0 | 1.60 | 2.00 | ♠ 52 | 59 | 90.0 |

| 052005 | 5-50 | M50 x 1.5 | 15 | 1½/2 | 21 | 34.0 | 44.5 | 52.5 | 53.0 | 2.00 | 2.50 | ♠ 65 | 73 | 100.0 |

| 052006 | 6-63 | M63 x 1.5 | 15 | 2/2½ | 21/30 | 44.0 | 56.5 | 65.5 | 70.0 | 2.00 | 2.50 | ♠ 80 | 90 | 120.0 |

| 052007 | 7-75 | M75 x 1.5 | 15 | 2½/3 | 30/32 | 56.0 | 67.5 | 78.0 | 78.0 | 2.50 | 3.15 | ♠ 96 | 108 | 120.0 |

| 052008 | 8-80 | M80 x 2.0 | 20 | 3 | 32 | 68.0 | 74.0 | 82.0 | 78.0 | 2.50 | 3.15 | ♠ 96 | 108 | 120.0 |

| 052009 | 9-90 | M90 x 2.0 | 20 | 3/3½ | 32/33 | 74.0 | 81.5 | 91.0 | 83.0 | 3.00 | 3.50 | ♠ 111 | 125 | 120.0 |

| 052010 | 10-100 | M100 x 2.0 | 20 | 3½/4 | 33/34 | 81.0 | 90.0 | 100.0 | 88.0 | 3.00 | 3.50 | - | - | 120.0 |

| 052011 | 11-110 | M110 x 2.0 | 20 | 4 | 34 | 86.0 | 98.0 | 114.0 | 92.0 | 3.00 | 4.00 | - | - | 120.0 |

| 052012 | 12-120 | M120 x 2.0 | 20 | - | - | 95.0 | 103.0 | 118.0 | 96.0 | 3.00 | 4.00 | - | - | 120.0 |

| 052013 | 13-130 | M130 x 2.0 | 20 | - | - | 100.0 | 115.0 | 124.0 | 100.0 | 3.00 | 4.00 | - | - | 120.0 |

|

All dimensions are in mm (apart from NPT). ♠ : For use with a CCG Hex Spanner. ♥ : When manufactured in Aluminium, Hex will be 27 Across Flats and 30 Across Corners. |

|