The Future of Power Transformer Connections: IEC Crimping vs Brazing & Welding

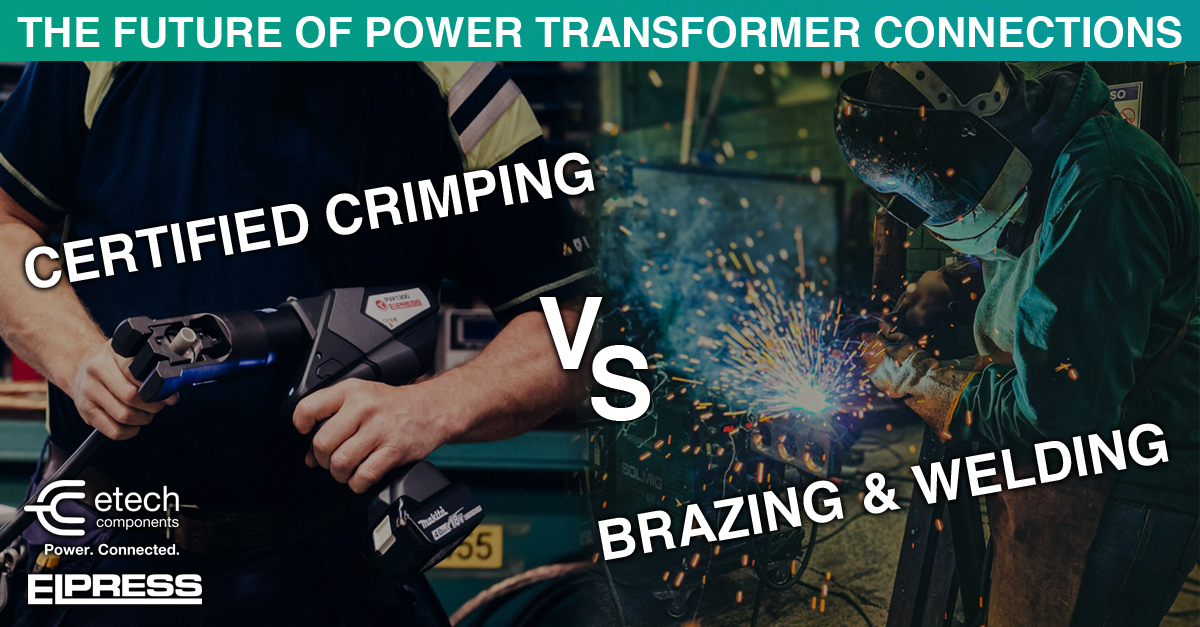

If you’re an Electrical Engineer, Lineman or Mechanical Technician, chances are you’ve crossed paths with Power Transformers over the years. The big, grey boxes with the cylindrical oil containment and preservation tank on top. Impressive on the outside? Sure. But it’s what’s inside that counts. The internal transformer connections, which are absolutely critical for electrical performance, thermal stability and long-term reliability. For years, the industry relied on brazing and welding to make coil lead-out connections. The problem? Operator attention to detail can vary widely, safety risks are higher and there’s very limited traceability of connection quality. If only there were a method that could offer better quality, repeatability, safety and measurable performance, all in one. Lucky for you, Elpress’ IEC 61238-1 Certified Crimping Systems do exactly that! Keep reading to see why transformer manufacturers worldwide are switching from transformer brazing and welding to IEC Certified Crimping for every critical connection.

What is Brazing and Welding? And what are Coil Lead-Out Connections?

Brazing and welding are traditional metal-joining methods that rely on heat to form permanent bonds. Welding works by melting the base metals themselves and fusing them together under very high temperatures and, in some cases, pressure.

Brazing, on the other hand, doesn’t melt the main metals. Instead, it uses a filler metal that flows into the joint at high temperature. This bonds the parts together through capillary action. Both methods can create strong, long-lasting joints. However, they rely heavily on heat, precise temperature control and operator skill, which is why their use in critical power transformer connections comes with real challenges.

As for coil lead-out connections in transformers, these are the points where the ends of the transformer windings (coils) are connected to the external circuitry or terminals. Essentially, they are the ‘exit points’ of the coils that allow the electrical current to flow from the internal windings of the transformer to the rest of the electrical system.

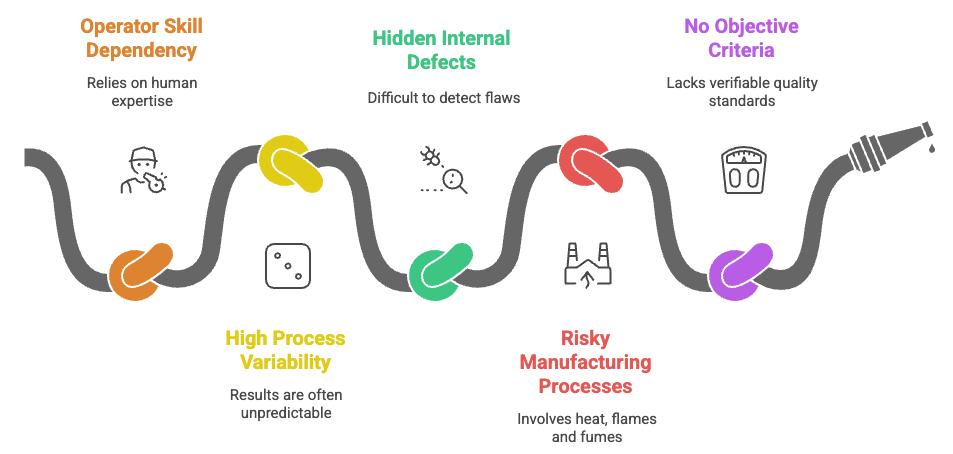

Disadvantages of Brazing and Welding in Power Transformer Connections

Just because people have done something a certain way for decades doesn’t mean it’s the best way. Brazing and welding may have served us well, but ignoring their limitations can put both workers and equipment at risk.

Quality transformer brazing and welding is heavily dependent on the operator’s skill. That means high variability, hidden internal defects that are hard to detect, and longer, riskier processes. Heat, flames and fumes are part of the job. So, you really need an experienced jointer when stakes are this high. And let’s be honest. There’s no objective way to verify joint quality. Taking someone’s word for it is all well and good until you start seeing energy loss, uneven connections, mechanical stress or even a transformer failure.

What is IEC 61238-1?

IEC 61238-1 is an International Standard created by the International Electrotechnical Commission (IEC) and was first published in 2018. The IEC itself has been around since 1906 and is recognised worldwide as the leading organisation responsible for developing international standards for electrical, electronic and related technologies.

The full title of the standard is “Compression and mechanical connectors for power cables – Part 1-1: Test methods and requirements for compression and mechanical connectors for power cables for rated voltages up to 1 kV (Um = 1.2 kV) tested on non-insulated conductors.” In simple terms, it lays out exactly how connectors must be tested and what they must achieve to be considered safe, reliable and fit for use.

This version of the standard replaced the older IEC 61238-1:2003, and the overall IEC 61238 series has now been split into multiple parts to cover different applications. These include connectors for non-insulated conductors up to 1 kV, insulation-piercing connectors for insulated conductors, and compression and mechanical connectors for higher-voltage applications up to 30 kV. The goal of the entire series is straightforward — to make sure crimped and mechanical connections perform consistently, safely and predictably in real-world power systems.

Why are Manufacturers Choosing IEC 61238-1 Certified Crimping?

At its core, the IEC 61238-1 Standard is an international benchmark for compression (crimp) connections in electrical power systems. It ensures that every crimped joint is safe, reliable and mechanically and electrically consistent.

Today, IEC 61238-1 is the global standard for crimping because it sets rigorous requirements for heat tolerance, contact resistance, thermal cycling, mechanical stability and long-term performance. By following this standard, manufacturers can guarantee that every coil lead-out connection meets the same high level of quality and reliability. This is something brazing and welding simply can’t ensure consistently.

IEC 61238-1 Transformer Crimping — The Perfect Brazing and Welding Alternative

Switching to an IEC 61238-1 Certified Crimping System brings several major advantages for transformer connections. Hydraulic Elpress tools provide repeatability and process control by delivering consistent force and deformation in every cycle, reducing the chance of human error.

They also offer higher operational safety, with no heat, flames or fumes. Just reliable, consistent crimps. Modern IEC Certified Crimping Systems support traceability and objective inspection through die identification on the terminal and precise crimp heights measurable with a calliper. This creates a fully verifiable process that manual brazing and welding simply cannot match.

On top of that, Certified Power Transformer Crimping Systems deliver superior electrical and thermal performance. This eliminates voids, reduces resistance and improves thermal behaviour under load cycling. This ensures that every transformer connection is configured for long-term reliability.

The High Price of Poor Quality

Want to know one of the most expensive and damaging events a manufacturer can experience? It’s a failure in an internal transformer connection, and the consequences are brutal.

Firstly, internal connection failures are a real nightmare. They are often extremely difficult, or downright impossible, to rework. This can bring production to a halt while everyone scrambles for a fix. On top of that, there’s the loss of valuable materials like oil, copper and insulation, which isn’t just frustrating — it’s costly. Then come warranty claims, logistics headaches and unhappy customers, not to mention the potential damage to your company’s reputation. And in the worst-case scenario, these failures can even lead to catastrophic transformer failure. This is the kind of thing that keeps Electrical Engineers, Linemen and Technicians awake at night!

Because transformer brazing and welding are operator-dependent, the risk of failure, and the associated costs, is significantly higher. Switching to IEC Certified Crimping Systems removes much of this uncertainty. Even tough coil lead-out connections can be safely completed using hydraulic Elpress tools designed for severe mechanical, electrical and thermal stress. Ultimately, Certified Power Transformer Crimping means controlled quality, reduced risks and lower failure costs.

Now You’ve Read Our Power Transformer Connections Guide, It’s Time to Make the Switch!

Switching to IEC 61238-1 Certified Power Transformer Crimping isn’t just a technical upgrade. It’s a strategic decision. You get higher safety, smoother operations, consistent quality, full traceability, better electrical performance and a significant reduction in costly failures.

For power transformer manufacturers, where every connection counts, Certified Crimping Systems are the most reliable, modern and robust way to ensure long-term performance. If you’re still relying on brazing and welding for your transformer connections, it’s time to consider IEC Certified Crimping. Your connections, your safety and your bottom line will thank you.

*This blog takes inspiration from this original article published by Victor Moraes, KAM Electrical Machines, Elpress Group on 26th November, 2025

| 📞 +44 (0)1744 762 929 | 📧 sales@etechcomponents.com | Elpress: Learn More |