Revealed: The 5 Solar and Wind Farm Components Driving Our Clean Energy Future

Many of you will recognise the classic iceberg graphic, often used to illustrate what’s visible above the surface versus what lies hidden beneath. Motivational speakers, therapists and school teachers all use it. The same idea applies to onshore/offshore UK wind farms and the towering turbines that dominate the landscape. While these turbines stand tall and commanding, it’s the wind farm components working behind the scenes that keep them running reliably. Often overlooked, these onshore/offshore connectors and accessories are critical pillars of the wind and solar energy transition. They make sure that farms and turbines not only look impressive but deliver on their crucial role in our clean energy future.

Many of you will recognise the classic iceberg graphic, often used to illustrate what’s visible above the surface versus what lies hidden beneath. Motivational speakers, therapists and school teachers all use it. The same idea applies to onshore/offshore UK wind farms and the towering turbines that dominate the landscape. While these turbines stand tall and commanding, it’s the wind farm components working behind the scenes that keep them running reliably. Often overlooked, these onshore/offshore connectors and accessories are critical pillars of the wind and solar energy transition. They make sure that farms and turbines not only look impressive but deliver on their crucial role in our clean energy future.

The Scale of the Challenge for UK Wind and Solar Farms

By 2050, over 70% of new energy capacity will need to come from wind and solar energy installations. This is the target set out in the IEA’s updated Net Zero Roadmap (2023) to achieve Net Zero CO₂ emissions in the energy sector. While many of us are familiar with the UK wind farms lining the A1(M), M1 and M6 motorways, that’s just the tip of the iceberg. UK wind farms extend far beyond our land mass, operating many miles out to sea. Beyond the UK, wind and solar farms also operate in some of the most challenging environments on Earth — from deserts to rugged mountains.

For example, offshore wind farms must withstand constant exposure to saltwater corrosion, while desert-based installations face extreme heat and aridity. In these conditions, wind farm components like joints, terminations and connectors bear just as much responsibility as the turbines and electrical panels we see. Without them, even the tallest, most powerful turbines wouldn’t deliver the reliable energy we depend on.

Discover Our Wind, Solar & BESS Range

Why Quality Accessories Matter

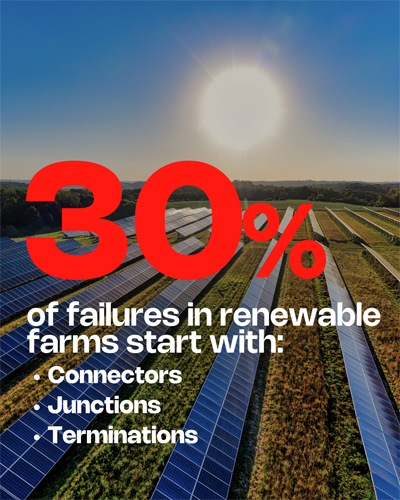

In business since 2004, E-Tech Components has over 20 years of expertise in Power Cable Accessories and Electrical Components. And our industry knowledge extends to wind farm products and wind farm solutions too. When it comes to this sector, here’s an important fact worth noting. Up to a third of turbine breakdowns actually start with faulty connections.

|

|

According to the 2022 WindEurope O&M Benchmarking study, it’s not always the blades or panels that cause problems. Faulty connections are a wind farm management nightmare. Associated downtime and unexpected outages can cost millions in lost power, delaying progress towards critical climate targets. Ultimately, it’s the unheralded joints, terminations and connectors working behind the scenes that keep turbines spinning reliably, day in and day out.

| Nexans Cable Joints | Nexans Cable Terminations & Kits | Euromold Separable Connectors |

The Weakest Link in Wind and Solar Energy

You can’t enjoy a day at the beach without the sun, and wind and solar energy infrastructure is no different. Without robust wind farm components, the whole operation can fall down — not literally, but certainly figuratively. Back in 2021, one of our blogs highlighted that A Crimping System is No Stronger than its Weakest Link. The same principle applies to UK wind and solar farms. Indeed, a single weak joint, termination or connector can compromise system integrity and interrupt power delivery.

You can’t enjoy a day at the beach without the sun, and wind and solar energy infrastructure is no different. Without robust wind farm components, the whole operation can fall down — not literally, but certainly figuratively. Back in 2021, one of our blogs highlighted that A Crimping System is No Stronger than its Weakest Link. The same principle applies to UK wind and solar farms. Indeed, a single weak joint, termination or connector can compromise system integrity and interrupt power delivery.

Fortunately, the industry is moving away from cheap, generic solutions to bespoke, intelligent components instead. Ultimately, these smart accessories help prevent downtime, extend lifespan and reduce overall operating costs.

The Top 5 Accessories for UK Wind and Solar Energy Farms

1. Smart Sensor-Equipped Accessories for Early Fault Detection

Mechanical stress, moisture ingress, vibrations and thermal fatigue are common causes of joint or termination failure. Offshore, these issues can go unnoticed for long periods, only becoming apparent when a power outage occurs.

That’s where smart, sensor-equipped accessories come in. Today, accessories are available with continuous monitoring of temperature and insulation health — like those used by Danish energy giant Ørsted. Integrated with Supervisory Control and Data Acquisition (SCADA) systems and predictive O&M schedules, these smart monitoring solutions are a significant step forward. Early fault detection allows preventative maintenance to take place, reducing the costly impact of unplanned downtime and keeping wind and solar energy installations operating reliably.

2. HV Offshore Connectors Built for Maximum Durability

Conditions hundreds of miles offshore are far harsher than a breezy day on Blackpool Beach – believe us! Constant wave motion and salt spray can quickly degrade standard connectors. That’s why offshore connectors like Nexans’ modular 145 kV solutions are purpose-built for UK offshore wind farms. Compact and flexible, they resist corrosion, fit into tight spaces and minimise bending forces on connected equipment. Also standing up to vibration and high pressure, they are ideal for the marine environment.

With fewer failures and longer gaps between maintenance, wind farm components like offshore connectors are a reliable, long-term investment.

3. Long-Lasting Materials Engineered for Extreme Conditions

We’ve already discussed the challenges of salt spray and moisture ingress. Along with UV exposure, these issues are inevitable in the harsh environments where UK wind farms operate.

We’ve already discussed the challenges of salt spray and moisture ingress. Along with UV exposure, these issues are inevitable in the harsh environments where UK wind farms operate.

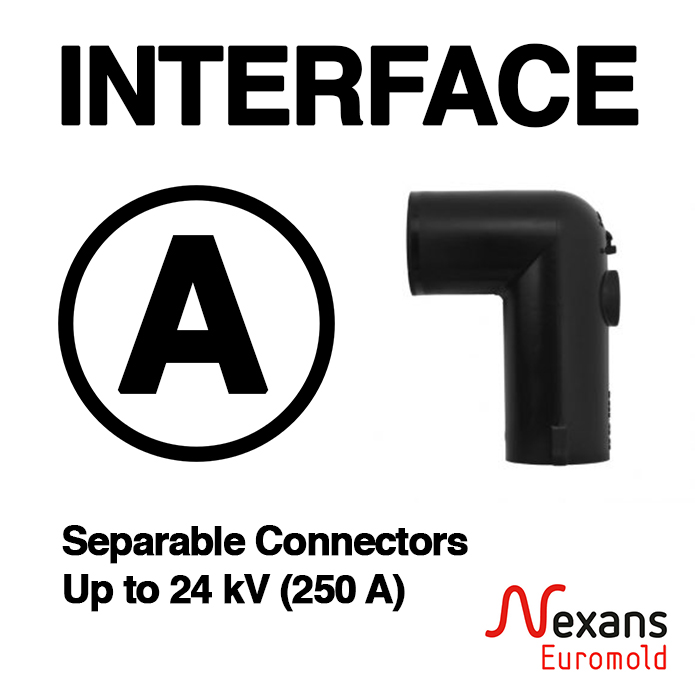

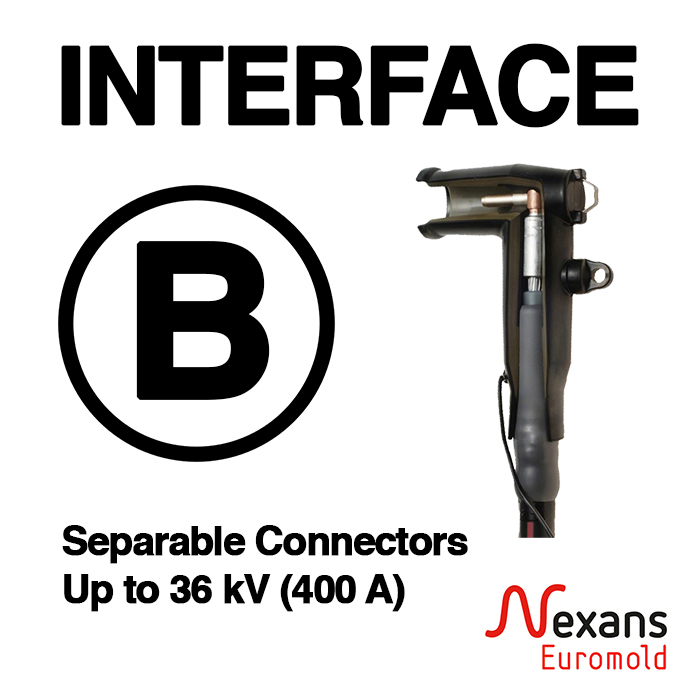

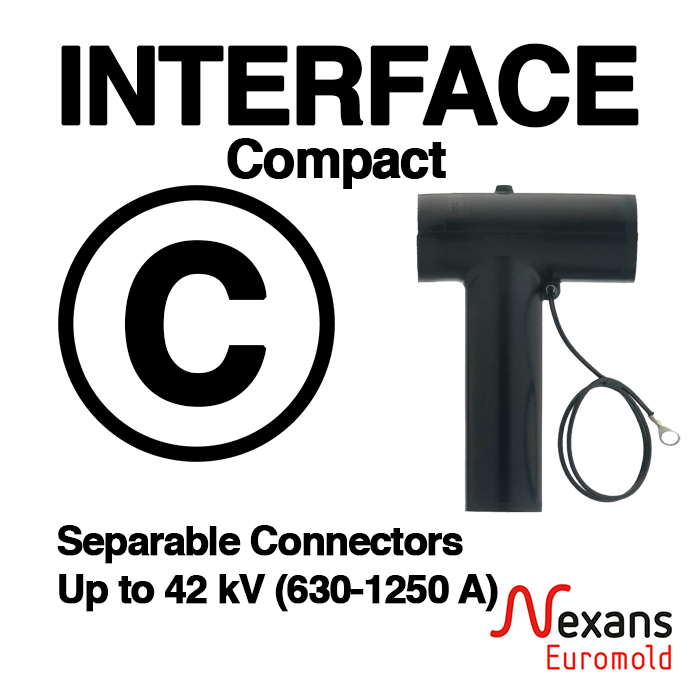

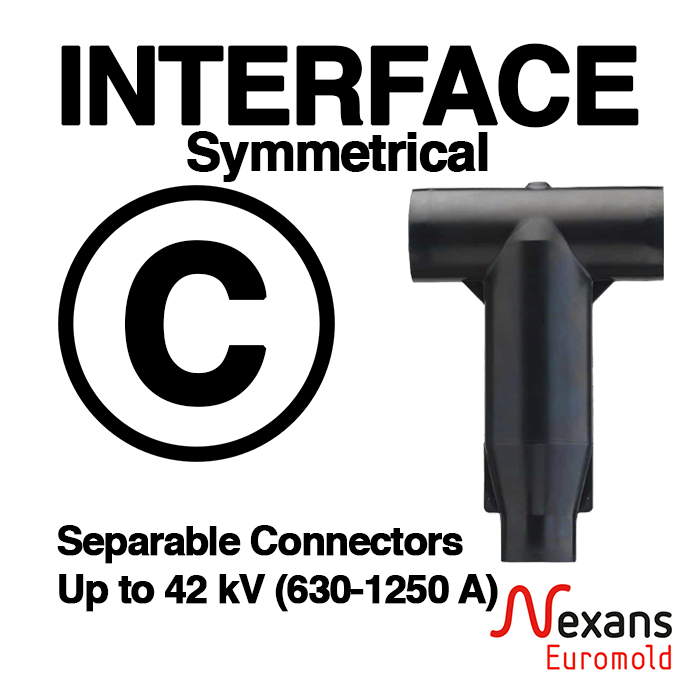

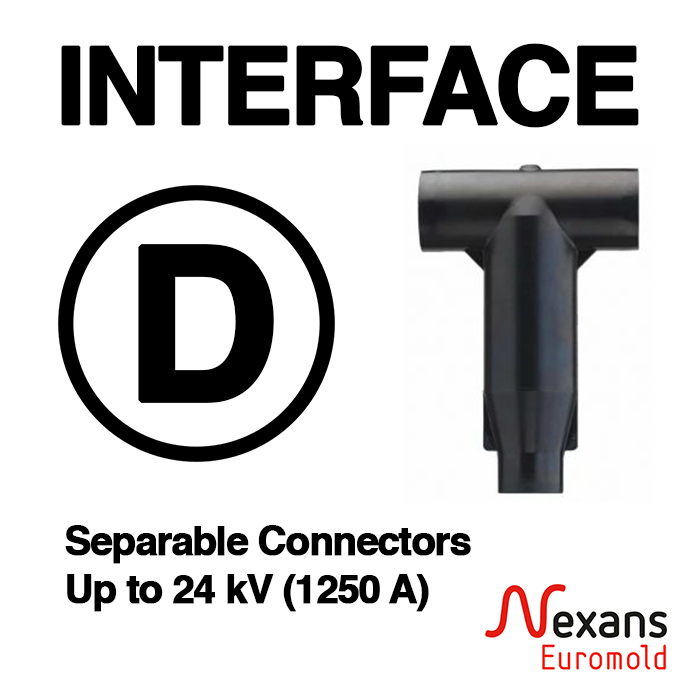

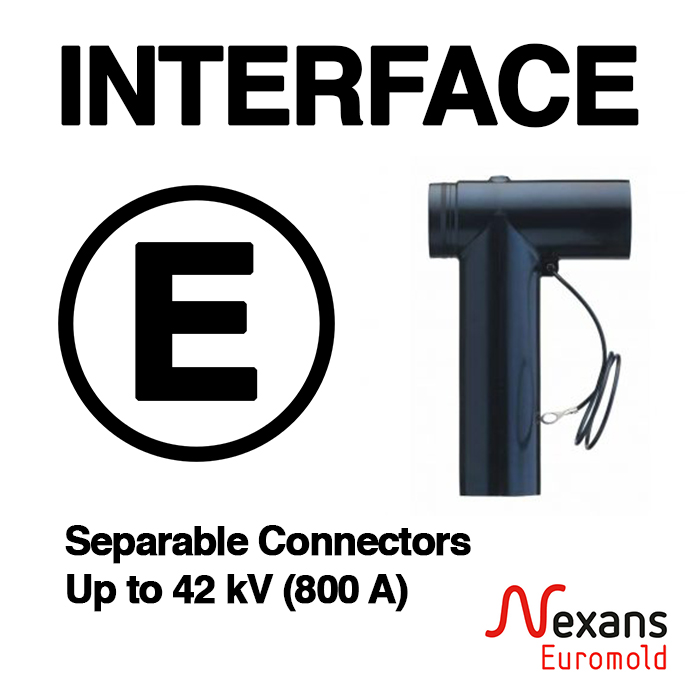

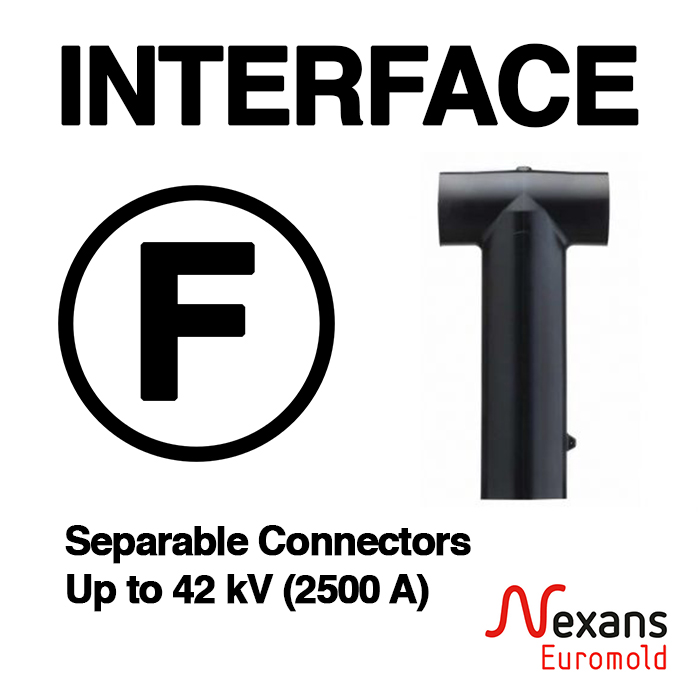

Fortunately, E-Tech Components offers Nexans Euromold Separable Connectors. Made with EPDM rubber, they provide proven electrical, mechanical and environmental resistance. These wind farm products maintain consistent dielectric properties, prevent partial discharges and deliver reliable performance over a long service life.

Learn More: Nexans Euromold Separable Connectors

Key features include:

- Fully screened, touchproof construction for personnel safety

- Ingress protection up to IP67/IP68 for watertight and dustproof sealing

- ATEX-certified versions for safe operation in explosive atmospheres

Long-lasting wind farm components like these help developers maximise ROI while taking care of uninterrupted power delivery.

4. Factory-Assembled Cable Systems to Reduce Installation Errors

At the end of the day, grid engineers and technicians are human. After their morning breakfast, these early risers spend hours on the motorway before climbing turbines and managing everything in between. Fatigue and human error can unfortunately lead to issues, with overtightening or misalignment threatening long-term performance.

Factory-assembled cable systems help address this challenge. By reducing on-site handling and streamlining installation, they not only minimise the risk of errors but also speed up deployment in harsh rural environments or when installing offshore connectors.

5. Customisable Modular Connector Kits Tailored to Each Site

No two UK wind farms or UK solar farms are identical. Some sit on high land, like The Hazlehead Wind Farm in the Peak District, while others, such as Gunfleet Sands Offshore Wind Farm, consist of 48 turbines located 4.3 miles off the Clacton-on-Sea coast. Modular connector kits allow installers to pre-assemble customised connectors suited to each site’s routing paths, reducing errors and project delays.

Considering the cost and effort of sending a service technician far out to sea for rework, investing in customisable modular connector kits can save significant time and expense while ensuring smoother project execution.

Conclusion: Prioritising Quality in Wind and Solar Energy

The UK Government’s legally binding Net Zero target for 2050 puts wind and solar energy at the heart of our clean energy future. But as this blog has highlighted, even the best turbines rely on high-quality wind farm components to operate efficiently.

By understanding and investing in offshore connectors, pre-assembled cable systems, sensor-based accessories, modular connector kits and high-performance materials, operators can make smarter decisions for UK wind farms and UK solar farms.

For tailored technical advice, specification support and the supply of high-performance wind farm products, E-Tech Components is here to help. Our expert team can guide you in selecting the right wind farm solutions for your application.

We’re an Official Nexans UK Kitting Provider

E-Tech Components is proud to be an official Nexans UK Kitting Provider, offering tailored solutions that simplify installation and enhance efficiency.

E-Tech Components is proud to be an official Nexans UK Kitting Provider, offering tailored solutions that simplify installation and enhance efficiency.

From Heat Shrink Joints and Terminations to Euromold Connectors, our pre-configured kits are designed to reduce on-site complexity, minimise waste and accelerate project delivery across the Power Distribution, Utilities and Infrastructure sectors. By combining our technical expertise with Nexans’ trusted products, we help teams across the UK build safe, reliable and efficient networks.

For Nexans product training, technical advice or tailored specification support, contact us today.

| 📞 +44 (0)1744 762 929 | 📧 sales@etechcomponents.com | Enquire Now |