Halogen Free Terminals: A trend or a necessity?

In a vast range of applications, engineers and project managers are encountering new industry requirements that are leading to the emergence of alternative “halogen-free” material-based wire management products (e.g. halogen free terminals/ LS0H or zero halogen). As industry requirements, environmental trends and risk prevention drive toward future growth of these products, there are still many questions to answer in order to specify their use.

What are halogens? What does “halogen free” mean? Why is it so important? And, in what applications is a halogen free product necessary?

What is a Halogen?

“Halogen” is a term referring to the five elements found in Group 17 of the Periodic Table. It means “salt-former” and compounds containing halogens are what we call “salts”.

“Halogen” is a term referring to the five elements found in Group 17 of the Periodic Table. It means “salt-former” and compounds containing halogens are what we call “salts”.

Originally there were four elements of the Periodic Table that produced a sea-salt like substance; Fluorine, Chlorine, Bromine and Iodine. During the atomic era, a 5th element, Astatine, was discovered. Nowadays, the latest is less famous due to its highly radioactive nature and short-lived isotopes.

Halogens are particularly useful elements in the production of electronics and plastics such as PVC and Teflon and are chosen in a wide variety of applications, from disinfectants to lighting. Astatine excluded, halogens are even significant for good health since the human body contains small amounts of all of them.

Halogen Free: What does it mean?

“Halogen Free Cabling” is a commonly used term in many areas of the cable and wiring industry, including aircraft, rail and construction. But why is being free of halogens a good thing?

Generally, “halogen free” means the product material does not contain any compounds derived from these elements. Other variations of the term that are commonly used are: Zero Halogen, No Halogen, 0H and ZH. The most common definition of the term Halogen Free in the electrical and electronic industry, would be the one suggested by IPC organization:

“Electrical and electronic products may be considered ‘halogen-free’ if they are assembled without the intentional use of these elements in the raw materials and these elements are not intentionally present in the end product.”

This definition implies that there is a chance that some unintentional halogenated compounds could be present in the form of material impurities or as the by-products of the production process. Therefore, when halogen-free material is necessary for wire management products, consideration should be given to all product attributes prior to selecting the product for use in a particular application. LS0H or zero halogen

What dangers are there when using Halogens in cabling?

During manufacturing processes, halogens are often added to components to make them withstand high temperatures and to be flame-retardant. One of the most popular cabling materials in use today is PVC (Polyvinyl Chloride). It is cheap, easy to use and very versatile, which has led to its adoption across a huge range of industries.

During manufacturing processes, halogens are often added to components to make them withstand high temperatures and to be flame-retardant. One of the most popular cabling materials in use today is PVC (Polyvinyl Chloride). It is cheap, easy to use and very versatile, which has led to its adoption across a huge range of industries.

However useful they may be as chemical biding blocks, halogens have some major drawbacks. They are highly reactive, creating nasty corrosive compounds when combined with other occurring materials, and have low melting points. In addition, they are pretty toxic themselves (Fluorine and Chlorine in particular) and in sufficient quantities, lethal to living organisms.

When halognated plastics burn, they release nasty and deadly gases into the atmosphere. Within restricted environments (e.g. interior of a ship or a tunnel) the concentration of these lethal gases can build very quickly, making escape in the case of a fire even more hazardous. Unfortunately, halogens are almost impossible to safely contain and history has proven this to be the case.

Why using Halogen Free products is so important?

Bearing in mind the above, we can easily understand the rise of Halogen-free materials and their use in electrical cables. Low smoke and halogen free products are used to protect wiring, as they are proven to limit the amount of toxic gas emitted when it comes into contact with heat.

Halogen free cabling is also easier to dispose of compared to other forms of cabling that emit toxic gasses when burned and can be toxic to dispose of by other means. Halogens used in electronic devices may not harm humans or the environment directly. However, they can definitely be harmful if a fire is involved or when proper recycling and disposal methods are not used, such as in developing countries.

Halogen free cabling is also easier to dispose of compared to other forms of cabling that emit toxic gasses when burned and can be toxic to dispose of by other means. Halogens used in electronic devices may not harm humans or the environment directly. However, they can definitely be harmful if a fire is involved or when proper recycling and disposal methods are not used, such as in developing countries.

Many advocates of halogen free cabling also argue that it is lower in weight, reducing the overall system weight, while also offering greater flexibility than other products.

These are the main reasons for the initiation of the “Halogen-Free” efforts. LS0H or zero halogen

Selecting the right product

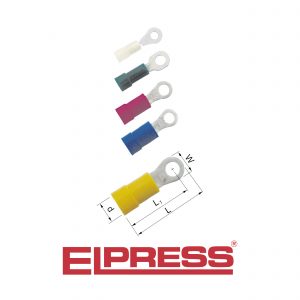

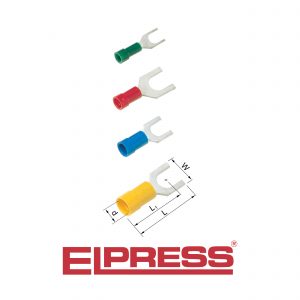

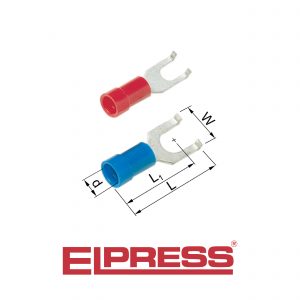

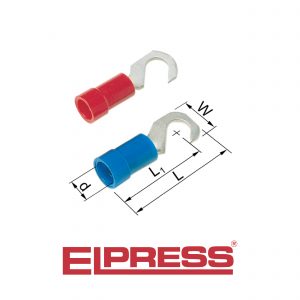

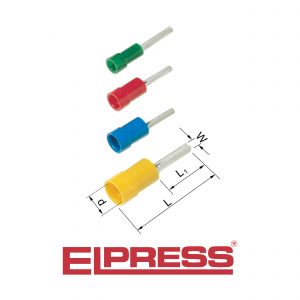

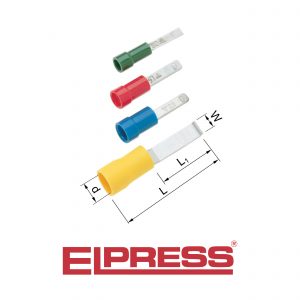

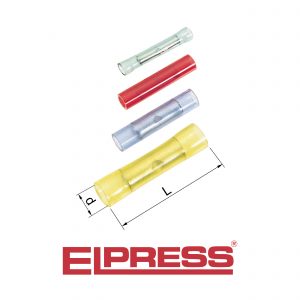

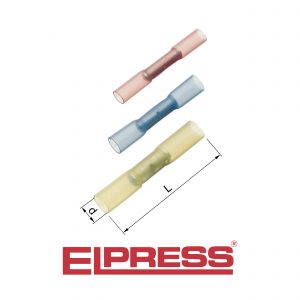

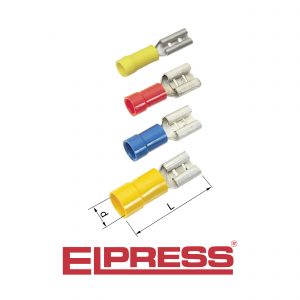

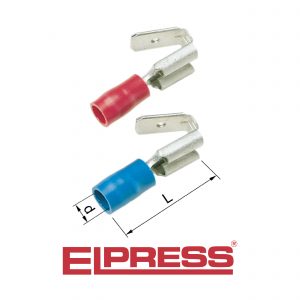

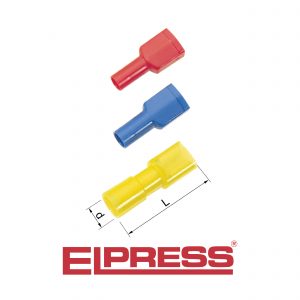

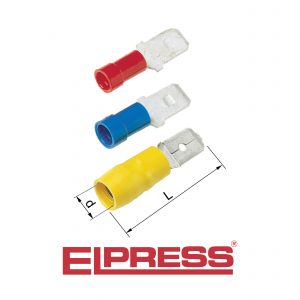

Elpress provide their customers with the option to make the change to halogen-free products, offering a big range of Pre-insulated Halogen Free Terminals. Most Elpress Pre-insulated Halogen Free Terminals & Connectors are using Polyamide (PA) or Polycarbonate (PC) as insulation material. Halogen free cables are engineered and designed so that emissions during a fire offer low toxicity and low smoke:

LS0H or zero halogen LS0H