Network Rail Duct Sealing System (Duct Seal HG): Understanding the PADS Number System

Table of Contents

- Introducing Duct Seal HG: A Network Rail Duct Sealing System

- Understanding the Network Rail Parts and Drawing System (PADS)

- Key Benefits of PADS

- Network Rail’s Uncontrolled Catalogue Numbers

- Duct Seal HG: A Network Rail Duct Sealing System

- Duct Seal HG: Key Features and Benefits

- First Deployment: Relocatable Equipment Buildings (REBs)

- Catalogue Numbers for Duct Seal HG

- Why Choose the Duct Seal HG Duct System?

- Conclusion: Enhancing Safety and Efficiency with Duct Seal HG: A Network Rail Duct Sealing System

- E-Tech Components – Power. Connected.

Introducing Duct Seal HG: A Network Rail Duct Sealing System

Ensuring safety, reliability and standardisation across railway infrastructure is essential. Network Rail’s Parts and Drawing System (PADS) plays a key role in achieving these goals by serving as a comprehensive database for approved products. Recently, Duct Seal HG from AC Cable Solutions earned recognition and compliance as a Network Rail Duct Sealing System. In this blog, we’ll delve into the importance of PADS, the role of uncontrolled catalogue numbers and how the Duct Seal Cable Duct System is redefining duct sealing solutions.

Understanding the Network Rail Parts and Drawing System (PADS)

PADS, or the Parts and Drawing System, is Network Rail’s comprehensive database for cataloguing and managing approved products across its extensive infrastructure. Each product is assigned a unique PADS number, ensuring traceability, standardisation and compatibility throughout the rail network. Duct Seal HG – a Network Rail PADS Approved Duct Sealing System – is now fully integrated, highlighting its importance in modern rail infrastructure.

Key Benefits of PADS

- Guarantees the safety, reliability and compatibility of railway products

- Simplifies product identification and management

- Streamlines the approval and integration of new solutions, such as Duct Seal HG – a Network Rail Approved Duct Sealing System

Network Rail’s Uncontrolled Catalogue Numbers

Uncontrolled catalogue numbers pertain to low-risk items that do not require formal acceptance from Network Rail Engineering. Managed by the Network Rail Catalogue Management Team within Route Services, these numbers ensure such items are systematically catalogued and readily available for procurement.

By simplifying the inclusion of low-risk items, uncontrolled numbers minimise administrative hurdles while maintaining efficient inventory management. Network Rail employees can access these through the iStore online procurement platform, streamlining operations for non-critical components. Products like AC Cable Solutions’ Network Rail Duct Sealing System (Duct Seal HG) benefit from such streamlined processes, ensuring rapid availability across projects.

Duct Seal HG: A Network Rail Duct Sealing System

Following rigorous trials and evaluations, the Duct Seal HG Duct System is now compliant for use across Network Rail sites. Fully catalogued with assigned PADS numbers, this system offers a professionally engineered solution for sealing ducts and cables.

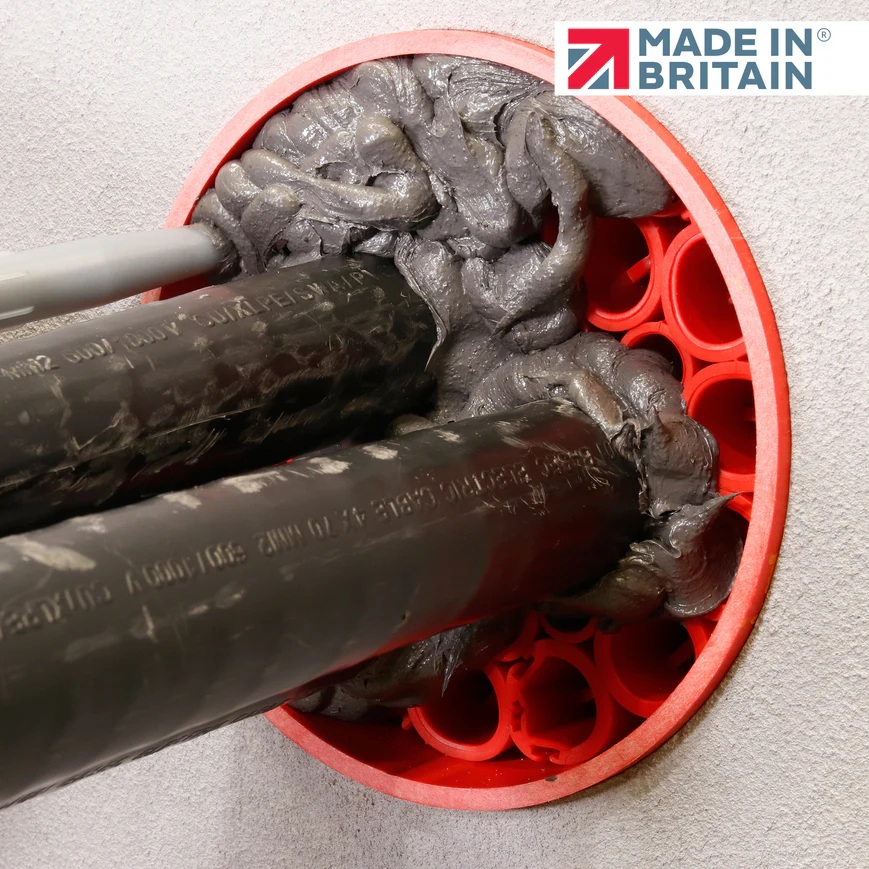

The Duct Seal HG Duct System is an advanced, patent-pending solution designed to provide reliable sealing and separation for large cables or pipes in harsh environments. Its unique tubular rubber backing can be configured as a continuous strip, ring, collar or cross shape, offering optimal support and separation for trefoil or triplex cables.

The system includes flexible, intumescent, zero-halogen sealants (GreyStuff or RedStuff) and provides exceptional protection for ducted networks and penetrations. Manufactured in the UK and independently age-tested for 50 years, the system is compliant with DSEAR, WIMES, DCG, APEA, BLUEBOOK, and ATEX standards.

Duct Seal HG: Key Features and Benefits

The Network Rail Duct Sealing System (Duct Seal HG) is a cutting-edge solution designed for durability and performance. Here’s what makes it stand out:

- Exceptional Sealing: Resists water, gas, and air pressure up to 2.0 bar

- Trefoil Separation: Unique patented design ensures optimal support for trefoil/triplex cables

- Safety and Compliance: MEKO-free, non-hazardous sealant meets DSEAR, WIMES, DCG and ATEX standards

- Flame Retardant: UL94 Certification for enhanced fire safety

- Versatility: Resistant to toxic gases and hydrocarbons, making it ideal for industries like water treatment and petrol forecourts

- Made in Britain: Proudly designed and manufactured in the UK, supporting local innovation

- Non-Adiabatic: Minimal Cable De-Rating: At a thickness of 20mm, thermal resistance is just 5.1 K/W, preserving the cable’s full current-carrying capacity

Its modular design allows for customisation, whether forming circular rings, cross-pieces or linear strips. This flexibility ensures robust, tailored solutions for various cable configurations.

First Deployment: Relocatable Equipment Buildings (REBs)

The Network Rail Duct Sealing System (Duct Seal HG) is currently in use for sealing cable entry points in Relocatable Equipment Buildings (REBs), which are being installed extensively across Network Rail infrastructure. Designed to secure cable transits, ducts and penetrations, the Duct Seal Cable Duct System (Duct Seal HG) is now an integral part of REB installations, enhancing efficiency and reliability.

Catalogue Numbers for Duct Seal HG

| Network Rail PADS – | ACCS Description & Part Number |

|---|---|

| 0086/002656 | SEAL DUCT HG DUCT SEALING SYSTEM (DSHG100) |

| 0086/002657 | SEALANT GREY STUFF INTUMESCENT DUCT SEALANT (GS310) |

| 0086/002658 | LARGE RUBBER SLEEVES – 27MM O/D – SET OF 5 (TRB27-19) |

| 0086/002659 | SMALL RUBBER SLEEVES – 18MM O/D – SET OF 5 (TRB18-12) |

| 0086/002660 | SPONGE FINISHING (SPONGECLOTH/3) |

| 0086/002661 | HIGH-PRESSURE SKELETON GUN – 310ML (SKELGUN310) |

Why Choose the Duct Seal HG Duct System?

- Always in stock, available off the shelf

- Perfect for trefoil cables with patented separation technology

- Long lifespan, age-tested for 50 years

- MEKO-free and non-hazardous for enhanced safety

- Minimal Cable De-Rating as it is non-diabatic: At a thickness of 20mm, thermal resistance is just 5.1 K/W, preserving the cable’s full current-carrying capacity

- Re-enterable and easy to install with no specialist tools required

- Backed by full training and technical support if needed

- Manufactured by a friendly, privately-owned UK business

Conclusion: Enhancing Safety and Efficiency with Duct Seal HG: A Network Rail Duct Sealing System

Network Rail’s commitment to safety, reliability and innovation is exemplified by the PADS system and the approval of Duct Seal HG. By cataloguing and managing products with rigorous standards, Network Rail ensures its infrastructure remains at the forefront of industry excellence.

Duct Seal HG’s advanced features, ease of use, and compliance with industry standards make it the ideal choice for sealing ducts and cables across Network Rail sites. Designed to meet the demands of modern rail infrastructure, it represents the future of efficient and reliable Duct Sealing Solutions.

E-Tech Components – Power. Connected.

E-Tech Components are a Specialist Distributor & Stockist of a comprehensive range of high-quality solutions that save time, reduce costs, improve quality and ensure compliance to industry standards and regulations for a wide range of industries.

Now available to download, E-Tech Components’ Company Brochure showcases our extensive range of Power Cable Accessories & Electrical Components:

- MV & HV Separable Connectors

- LV, MV & HV Cable Joints, Terminations, Accessories & Tools

- Complete Crimping Systems

- Cable Management & Protection Solutions

- Other Power Cable Accessories & Components

Curious to know more about our offerings? Check out our Company Brochure: