Elpress Un-Insulated Tube Terminals (0.75-10mm²)

Product overview

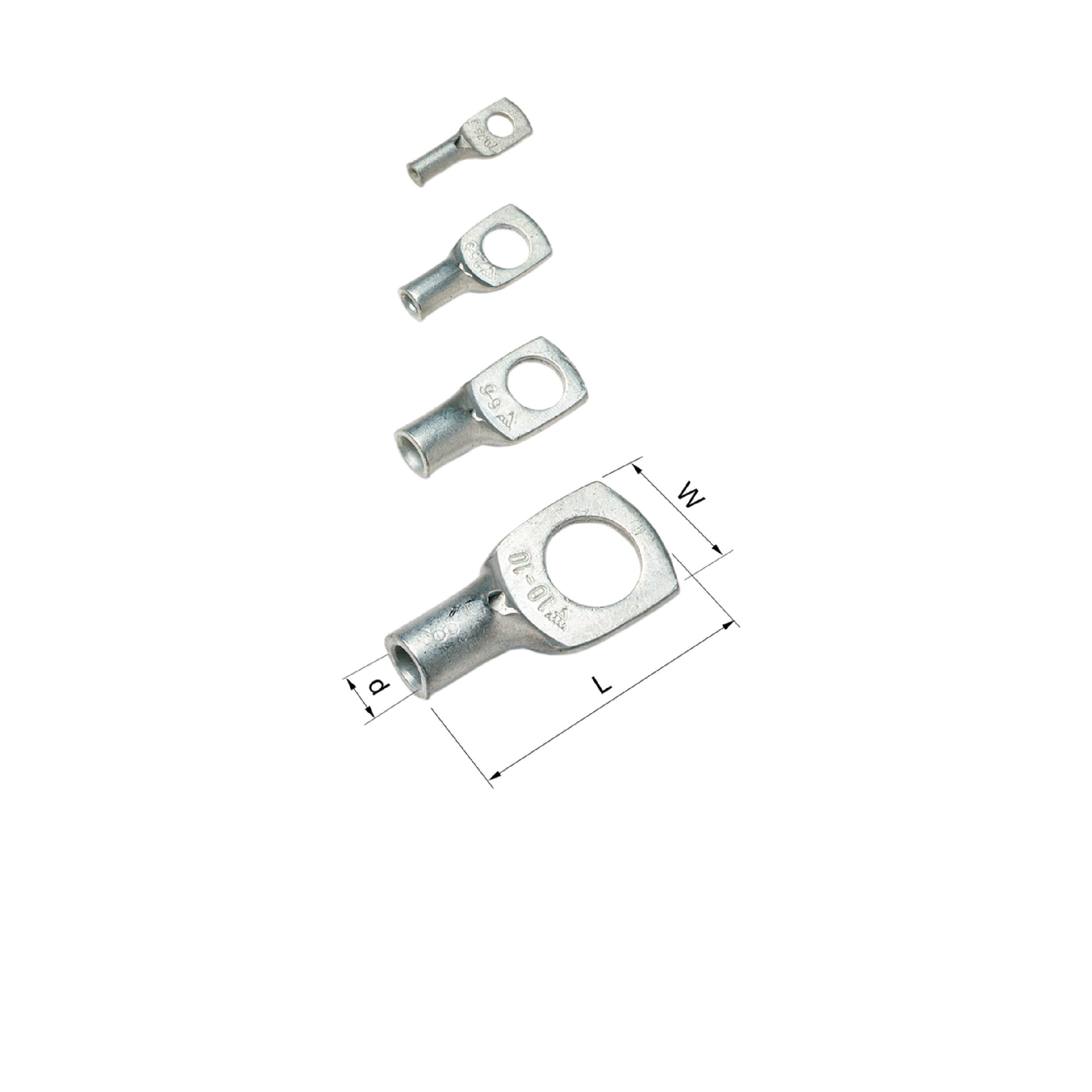

Elpress Un-Insulated Tube Terminals

Elpress Un-Insulated Tube Terminals (Range 0.75-10mm²) are made from high grade 99.95% copper (Cu), are tin plated and UL-approved.

Elpress Un-Insulated Tube Terminals (Range 0.75-10mm²) are made from high grade 99.95% copper (Cu), are tin plated and UL-approved.

Part Numbers: Elpress KR0,75-3, KR0,75-4, KR1,5-3, KR1,5-4, KR1,5-5, KR2,5-3, KR2,5-4, KR2,5-5, KR2,5-6, KR4-3, KR4-4, KR4-5, KR4-6, KR6-4, KR6-5, KR6-6, KR6-8, KR10-4, KR10-5, KR10-6, KR10-8, KR10-10, KR10-12.

*Please note, Part Numbers highlighted in bold are Network Rail-approved according to PADS Certificate PA05/07403. This refers to sizes 6-10mm².

General Information

SYSTEM ELPRESS

System Elpress consists of Terminals and Tools designed and tested together to give a certified crimping result. This ensures that users will feel confident when using our systems, and the achievement of a secure connection through the proper handling of our products. By using Elpress Cu-Connection elements together with one of Elpress Crimp Systems one obtains a connection tested according to the requirements of IEC 61238:1.

UN-INSULATED TERMINALS

Elpress Through Connectors, Ring, Pipe, Fork and Pin terminals produced from high quality Copper 99.95%. The Receptacles and Sockets made of brass. All terminals then get electro-tin plating for maximum corrosion protection. Terminals made of copper bands have a brazed soldered neck, which means that user can crimp them in any direction.

Marking & Approvals

LABELLING

Elpress uninsulated terminals have a clear marking with logotype, area and any screw diameter to facilitate work and checkability.

UL-APPROVED TERMINALS

KR/ KS, KRF/ KRS, KRFS, KRT/ KST UL-approved in accordance with file no E205350. UL-certified products delivered with UL marking on the label including the UL file number and/ or certification code for control by an UL inspector. You can download the certificate at UL Product IQ.

For more information on Elpress Un-Insulated Tube Terminals (KR10-6, KR10-8, KR10-10, KR10-12), see Technical Data below.6

*Technical Data subject to change without notice.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Interested in this Product?

+44 (0)1744 762 929Technical Data

- Material: Cu 99.95%, tin plated Cu/Sn.

- For multi-stranded (class 5) and stranded (class 2) Cu conductors

- UL-approved (1.5-10mm²)

| Cat. No. | mm² | AWG | Screw | mm W | d | N | N1 | P | L | t | s | Rec. Tool | Inspection Hole | Die | Pcs / Pack |

| KR0,75-3 | 0,75 | (22)-18 | M3 | 6 | 1,3 | 3,2 | 3,8 | 7 | 17 | 0,85 | 7,5 | DKB0325, DKB0760 | No | 100 | |

| KR0,75-4 | 0,75 | (22)-18 | M4 | 6 | 1,3 | 3,2 | 3,5 | 6,7 | 17 | 0,8 | 7,5 | DKB0325, DKB0760 | No | 100 | |

| KR1,5-3 | 1,5 | (18)-16 | M3 | 6,5 | 1,8 | 3,4 | 3,6 | 7 | 16 | 1 | 7,5 | DKB0325, DKB0760 | No | 100 | |

| KR1,5-4 | 1,5 | (18)-16 | M4 | 6,5 | 1,8 | 4,2 | 3,8 | 8 | 17 | 0,9 | 7,5 | DKB0325, DKB0760 | No | 100 | |

| KR1,5-5 | 1,5 | (18)-16 | M5 | 7,5 | 1,8 | 4,8 | 4,7 | 9,5 | 18 | 0,85 | 7,5 | DKB0325, DKB0760 | No | 100 | |

| KR2,5-3 | 2,5 | (16)-14 | M3 | 7,5 | 2,3 | 3,5 | 4,1 | 7,6 | 17 | 1,3 | 7 | DKB0325, DKB0760 | No | 100 | |

| KR2,5-4 | 2,5 | (16)-14 | M4 | 7,5 | 2,3 | 4,2 | 4,1 | 8,3 | 18 | 1,3 | 7 | DKB0325, DKB0760 | No | 100 | |

| KR2,5-5 | 2,5 | (16)-14 | M5 | 8,5 | 2,3 | 4,8 | 4,8 | 9,6 | 19 | 1,1 | 7 | DKB0325, DKB0760 | No | 100 | |

| KR2,5-6 | 2,5 | (16)-14 | M6 | 8,5 | 2,4 | 5,1 | 5,8 | 10,9 | 19 | 1,1 | 7 | DKB0325, DKB0760 | No | 100 | |

| KR4-3 | 4 | 12 | M3 | 8,5 | 3 | 4,2 | 5,8 | 10 | 21 | 1,5 | 8,5 | GWB4099, ES2258 | Yes | 100 | |

| KR4-4 | 4 | 12 | M4 | 8,5 | 3 | 4,2 | 5,8 | 10 | 22 | 1,5 | 8,5 | GWB4099, ES2258 | Yes | 100 | |

| KR4-5 | 4 | 12 | M5 | 9 | 3 | 4,8 | 5,2 | 10 | 22 | 1,5 | 8,5 | GWB4099, ES2258 | Yes | 100 | |

| KR4-6 | 4 | 12 | M6 | 9,9 | 3 | 5 | 7 | 12 | 23 | 1,3 | 8,5 | GWB4099, ES2258 | Yes | 100 | |

| KR6-4 | 6 | 10 | M4 | 9,5 | 4 | 4 | 6 | 10 | 22 | 1,7 | 8,5 | GWB4099, ES2258 | Yes | 100 | |

| KR6-5 | 6 | 10 | M5 | 9,5 | 4 | 5 | 6 | 11 | 22 | 1,7 | 8,5 | GWB4099, ES2258 | Yes | 100 | |

| KR6-6 | 6 | 10 | M6 | 9,9 | 4 | 5,5 | 6,5 | 12 | 23 | 1,6 | 8,5 | GWB4099, ES2258 | Yes | 100 | |

| KR6-8 | 6 | 10 | M8 | 13 | 4 | 7 | 10 | 17 | 30 | 1,2 | 8,5 | GWB4099, ES2258 | Yes | 100 | |

| KR10-4 | 10 | 8 | M4 | 11,5 | 5 | 6 | 8 | 14 | 29 | 2,9 | 11 | GWB4099, ES2258, PVL350, V600, DV1300 | Yes | 8 | 100 |

| KR10-5 | 10 | 8 | M5 | 11,5 | 5 | 6 | 7,5 | 13,5 | 29 | 2,9 | 11 | GWB4099, ES2258, PVL350, V600, DV1300 | Yes | 8 | 100 |

| KR10-6 | 10 | 8 | M6 | 11,5 | 5 | 6 | 7,5 | 13,5 | 29 | 3 | 11 | GWB4099, ES2258, PVL350, V600, DV1300 | Yes | 8 | 100 |

| KR10-8 | 10 | 8 | M8 | 13,5 | 5 | 7,5 | 8,5 | 16 | 33 | 2,3 | 11 | GWB4099, ES2258, PVL350, V600, DV1300 | Yes | 8 | 100 |

| KR10-10 | 10 | 8 | M10 | 16 | 5 | 8 | 10 | 18 | 34 | 2 | 11 | GWB4099, ES2258, PVL350, V600, DV1300 | Yes | 8 | 100 |

| KR10-12 | 10 | 8 | M12 | 18,5 | 5 | 10 | 13,5 | 23,5 | 41 | 1,7 | 11 | GWB4099, ES2258, PVL350, V600, DV1300 | Yes | 8 | 100 |

t=palm thickness, s= strip length