Filoform FiloSeal+HD Duct Seal

Product overview

Filoform FiloSeal+HD Duct Sealing System is an engineered universal solution for sealing larger heavy cables and pipes in ducts, boreholes or transit frames. It is suitable for sealing any cable configuration or pipes contained in one duct and also allows easy re-entry of the seal to add or remove cables or pipes as required.

Filoform Part Numbers: FiloSeal+HD – 75mm > 110mm (280010), FiloSeal+HD – 125mm > 160mm (280020), FiloSeal+HD – 180mm (280030), FiloSeal+HD – 200mm (280040), FiloSeal+HD – 225mm (280050), FiloSeal+HD – 250mm (280060).

- Up to 2 bar Pressure Resistance

- 100Kg pulling Force on the cables when sealed

- 10xd at 45º, with 1 bar pressure bending test

If Fire resistance is required, click here for FiloSeal+HD FIRE.

Application Process

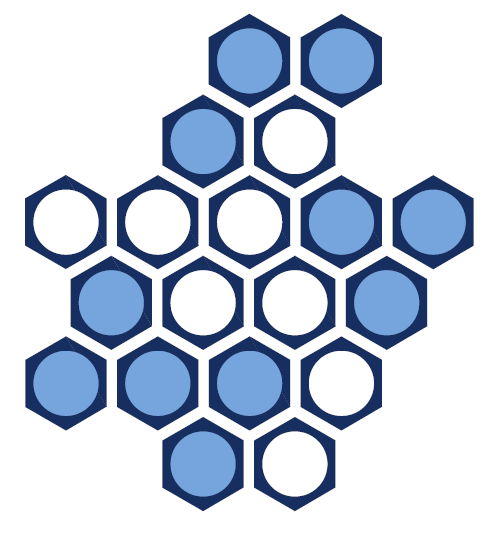

Filoform FiloSeal+HD (280010, 280020, 280030, 280040, 280050, 280060) is an engineered solution that provides a strong support system using the hexagonal tubes which builds up like a honeycomb structure.

The Filoform duct sealing system FiloSeal+HD uses our MD+ sealant which is easily applied from a standard skeleton gun. The high quality, one component, flexible sealant “MD+” is based on a silicon compound that cures with air (Humidity).

After application and full curing the thixotropic MD+ forms a plastic elastomer mass with special qualities effectively sealing and bonding, while providing a high level of durability.

Very easy to apply regardless of the type of cable scenario in the cable ducts as it uses strong, but flexible hexagonal tubes to support the cable and provide a strong backing for the seal

The unique design of the hexagonal tubes makes positioning and separation of the cables very simple while also providing a strong backing for the MD+ to be applied on.

Filoform FiloSeal+HD Duct Seal – Key Features

- Flexible, one component, adhesive and sealing compound in a cartridge – (310ml)

- Kits are complete with backing and mastic to fill an empty duct of the quoted kit size

- High levels of Gas and Water tightness

- Excellent adhesion, applicable to all common building materials

- Shows Fire resistance properties

- Resistant against Water, Alkaline, Chemical agents

- Resistant to termites (Mastotermes Darwiniensis) Northern Australian termites

- Resistant to Rats

- Resistant to Hydrogen Sulphide / Methane and many other Gases (NedLab)

- Non-corrosive

- Solvent-free

- Shock absorbing

- Non-toxic, neutral and almost odourless

- Also suitable for limiting the EX-zones during transitions (observe chemical resistance)

- Complies with 2011 NEC Articles 225.27, 230.8, 300.5(G), 300.7 (A) on Raceway Seals, and 501.15 (B)(2)

- Suitable for any shaped duct/borehole/opening

- WIMES Compliant (3.02 2013 6.4.3.2 b)

- Quick and easy installation

- A complete kit

- Seals all know materials, PVC & PE sheathed cables, PILC, (HD) PE pipes

- Engineering duct sealing solution

- Suitable for renovations, can be installed retrospectively

- Over 25 years of operational experience

For Additional Information on Filoform FiloSeal+HD Duct Seal (280010, 280020, 280030, 280040, 280050, 280060), please refer to the Technical Data Table below or download PDF File.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Interested in this Product?

+44 (0)1744 762 929Technical Data

| Part Number | Product Name | Duct Diameter Min - Max (mm) |

Order Unit |

| 280010 | FiloSeal+HD - 75mm > 110mm | Ø 110 max. | per piece |

| 280020 | FiloSeal+HD - 125mm > 160mm | Ø 160 max. | per piece |

| 280030 | FiloSeal+HD - 180mm | Ø 180 max. | per piece |

| 280040 | FiloSeal+HD - 200mm | Ø 200 max. | per piece |

| 280050 | FiloSeal+HD - 225mm | Ø 225 max. | per piece |

| 280060 | FiloSeal+HD - 250mm | Ø 250 max. | per piece |

Specifications |

| Property | Value | Standard |

| Density | 1.2 gr/cm³ | - |

| Pressure | up to 2 bar | - |

| Pulling Force | 100kg (1000 newtons) | - |

| Bend Test | 10xd at 45º, with 1 bar pressure | - |

| Flow | < 2mm | ISO 7390 |

| Colour | red-brown | - |

| Skin over time (23C/55%RH) | ± 15 minutes | - |

| Curing | 3 mm / 24 hours | - |

| Hardness | 30 shore A | DIN 53505 |

| Elongation | 100% | DIN 53504 |

| Tensile strength | 0.8 N/mm² | DIN 53504 |

| Operating temperature | +5°C to +40°C | - |

| Temperature resistance | -40°C to +120°C | - |