Filoform MD5 Duct Sealing System

Product overview

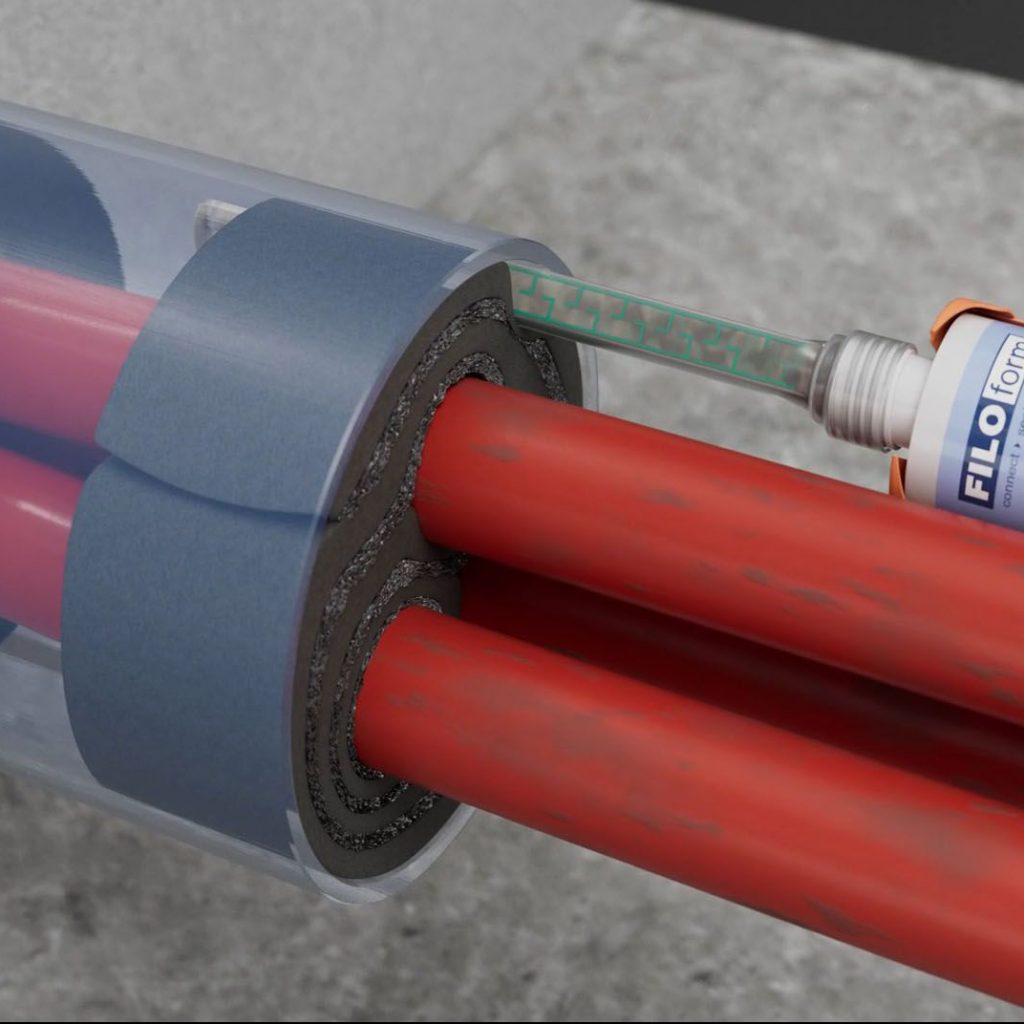

Filoform MD5 Duct Sealing System is designed to provide an effective and straightforward solution for gas and watertight sealing of one or multiple cables/conduits in ducts or boreholes. MD5 protects against damage caused by gas and water leaks.

Filoform Part Numbers: MD5-160mm (80347), MD5-110mm (80345).

This duct sealing system is highly flexible in use and installation can take place in vertical and horizontal duct or boreholes, and is suitable for boreholes at any angle.

Filoform MD5 Duct Sealing System – Application Process

The MD5 duct sealing system (MD5-160mm – 80347, MD5-110mm – 80345) uses a specially formulated two-component expanding polyurethane resin. The polyurethane sealant comes in a two-component cartridge. The two liquid parts are formulated to be mixed at a 1:1 ratio, using the 2K cartridge and mixing nozzle provided.

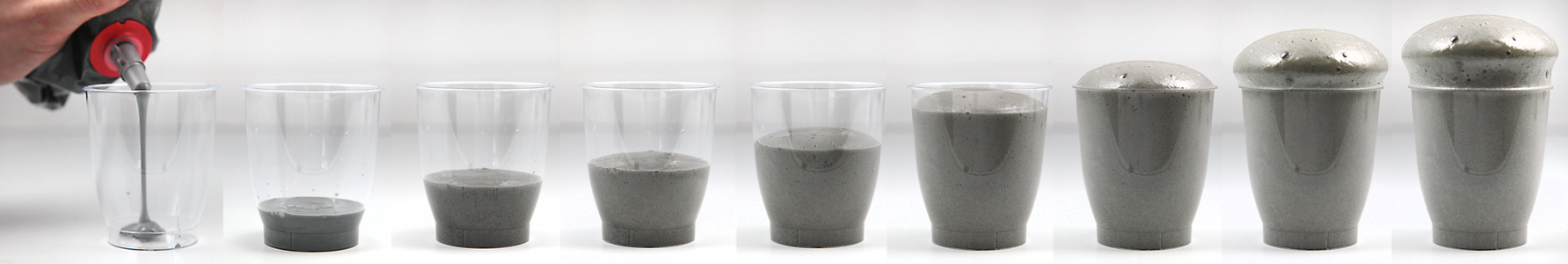

After injecting the resin into the duct, the resin starts expanding by forming CO². During the expansion, the polyurethane resin penetrates all areas between the two foam flanges inside the duct. MD5 is suitable for all openings regardless of the shape of the duct or borehole and cable configuration.

After full curing, the Filoform two-component resin provides a 100% gas and watertight seal and offers excellent mechanical strength & rodent resistance. Filoform MD5-160mm (80347), MD5-110mm (80345) are compatible with common cable jacket /sheath materials and PE drinking water conduits. The cured duct sealant is an inert solid mass that does not affect any of the materials inside of the duct.

Filoform MD5 System (MD5-160mm – 80347, MD5-110mm – 80345) supports and separates multiple cables in a duct / conduit using our uniquely designed duplex foam. At the same time, it reduces excess expansion of resin out the front of the duct. This ensures a neater, less messy professional finish. The opening of the duct does not need to be completely round.

Filoform MD5 – Installation

- One box solution: Everything needed to seal one duct end (except a caulking gun).

- Cable Separation: It is vital to firmly wrap the duplex foam around each cable, to create separation from each other and the inside of the duct.

- Running water: The duct & cables must be as dry as possible with no running water and free from any dirt, oil, greese & debris. MD5’s resin can cope with small amounts of moisture in the duct or on the cables, but larger amounts of water will reduce the effectiveness. Please contact our technical department if you have any questions.

Cure time

MD5 resin’s installation can take place in temperatures from 5°C (41°F). In colder temperatures, expansion can be slower but will expand and cure over a more extended time. Expansion time between 8-10 minutes at temperature ranging between 15-20°C.

Cleaning

Should any un-mixed material spill onto a surface, clean the area using a solvent wipe.

Reentering & removal

Properties of Cured resin: Fairley dense structure however can be dug out with a blunt tool & Hammer with some degree of difficulty.(Please note there is between 10-15 cm (4-6”) of the expanding resin in each seal depending on the size of duct)

- Remove all of the front foam that is separating the cables with a pair of pliers or cutting tool

- Using a hammer & chisel or similar tool to break the seal around the cable and the inside of the duct

- If there is room and the cables are de-energized, a power tool to speed the process up could be used. Once the seal is broken from the cable, there may be a crust of resin still present on the cable. This is due to the excellent adhesion of the resin. The hardest part of removing this seal is the crust that forms when the resin soaks into the foam flange.

Filoform MD5 – Safety

MD5’s specially formulated two-component resin is part of the same chemical/product family of similar electrical and construction industry products. These products have been widely used for decades. As with all two-component resins, read thoroughly the safety precautions to handle and install these types of materials. MD5’s resin comes in a state of the art 2K cartridge, which reduces contact with the raw materials. When mixing the two components, the resin expands and forms a high density, closed-cell polyurethane foam and is inert and non-toxic when fully cured.

Storage conditions

Keep the cartridges in a cool, dry environment and away from direct sunlight. Product shelf life is 18 months. Providing the installer insert the cap correctly after use, then you can still use the remaining product in the cartridge within two months of opening.

Filoform MD5 Duct Sealing System – Specifications & Standards

- Gas and watertight up to 1.5 bar / 21 PSI (30 days)

- Gas and watertight up to 2.5 bar (7 days)

- After injecting, the polyurethane sealant will expand and cures/hardens with a high density and a closed cell structure

- Easy and quick installation

- One complete kit – Everything you need except for a standard caulking gun

- Suitable for single & multiple cables

- Compatible with a wide range of cable and conduit materials: PVC & PEsheathed cables, PILC cables, (HD)PE ducts, & PE drinking water conduits

- High mechanical strength, resists ground movement, shocks and vibrations

- Complies with DIN 18322 underground cable laying works – gas & watertight cable and conduit entries into buildings

- Complies with 2011 NEC Articles 225.27, 230.8, 300.5(G), 300.7 (A) on Raceway Seals, and 501.15

For Additional Information on Filoform MD5 Duct Sealing System (MD5-160mm – 80347, MD5-110mm – 80345), please refer to the Technical Data Table below or download PDF File.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Interested in this Product?

+44 (0)1744 762 929Technical Data

| Part Number | Product Name | Duct Diameter Min - Max (mm) |

Order Unit | |

| 80347 | MD5-160mm | Ø 160 max. | per piece | |

| 80345 | MD5-110mm | Ø 110 max. | per piece |

Expanding Resin Specifications |

| Properties | Unit | Value |

| Start time expansion | Seconds | 50-70 |

| End time expansion | Minutes | 8-10 |

| Curing time (Tack-Free time) | Minutes | >12 |

| Compressive strength | N / cm² | >60 |

| Density | kg / m³ | 90-110 |

| Thermal resistance long term | °C | 100 |

| Closed cell percentage | % | >90 |

| Thermal aging, 28d 90°C | no visual damage | V |

| Form stability, size and visual | % | <1 |

| Compression strength after aging | N / cm² | >40 |

| Weight loss after aging | % | <0,5 |

| Water absorption, at 40 years, fully immerged | % | <10 |

| Water absorption 28 days at 90 °C | % | <5 |

| Weight loss max. | % | 0,5 |

| Compression strength after Hydrolysis test | N / cm² | >40 |

| Form stability after Hydrolysis test | Visual | PASS |

| Chemical resistance |

| 0,1N Na₂SO₄: 30 days - PASS |

| 0,1N NaCl: 30 days - PASS |

| 0,1N H₂SO₄: 30 days - PASS |

| 0,1N NaOH: 30 days - PASS |

| Diesel: 30 days - PASS |

| Gasoline: 30 days - PASS |

| H2S, 200 ppm: 5 days, 40°C, 95% air humidity - PASS |

| Resistance |

| Moulds: good |

| Rodents: good |

| Shelf life: 18 months |