Filoform MDI Duct Sealing System

Product overview

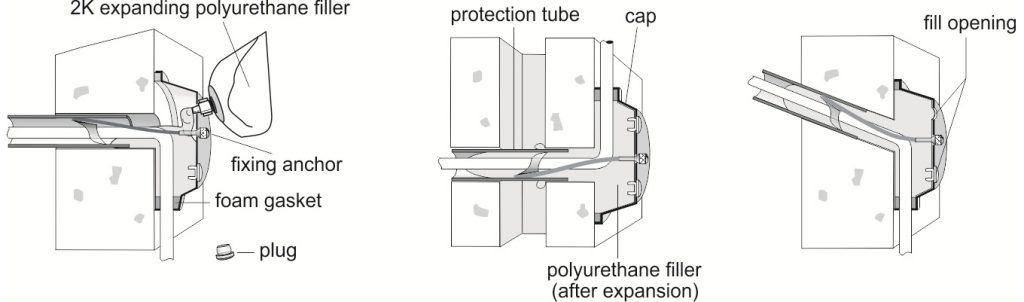

Filoform MDI Duct Sealing System has been developed for sealing ducts containing pliable cables such as coax and rubberised cables, which can be easily bent to a right angle. Suitable for ducts with a diameter of 16mm up to 60mm and cables or pipes with a diameter up to 25mm.

Filoform Part Numbers: MDI-1 (280220), MDI-2 (280223P)

This system allows these usually vulnerable cables to be sealed anywhere along a wall where the cable enters a building. Filoform Duct Sealing Systems are specified and used by major Electrical, Gas, & Water Utility companies in the UK and Benelux countries.

Filoform MDI Duct Sealing System – Key Features

- High levels of Gas and Water tightness

- Resistant to Hydrogen Sulphide / Methane and many other Gases

- Complies with ATEX regulations

- Suitable for ducts / bore holes

- Quick and easy installation

- A complete kit for one duct

- Seals all know materials, PVC & PE sheathed cables, PILC, (HD) PE pipes

- Excellent mechanical strength, after curing resistant to movements, shocks and vibrations

- Suitable for renovations, installation can take place retrospectively

- Over 25 years of operational experience

For Additional Information on Filoform MDI Duct Sealing System (MDI-1, MDI-2), please refer to the Technical Data Table below or download PDF File.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Interested in this Product?

+44 (0)1744 762 929Technical Data

| Part Number | Product Name | Duct Diameter Min - Max (mm) |

Max Cable Diameter in the duct (mm) |

Order Unit |

| 280220 | MDI-1 25mm duct sealing kit | Ø 16-32 | Ø 12,5 max. | per piece |

| 280223P | MDI-2 50mm duct sealing kit | Ø 32-60 | Ø 25 max. | per piece |

Dimensions Cap |

| Item Number | Outer Diameter | Inner Diameter | Height |

| 80221 | 104 mm | 72 mm | 30 mm |

| 80223 | 132 mm | 106 mm | 45 mm |

Expanding Resin Specifications |

| Properties | Unit | Value |

| Start time expansion | seconds | > 95 |

| End time expansion | minutes | 15 |

| Compressive strength | N / cm² | > 100 |

| Density 0,5bar | 30 days | no leakage |

| Density 5m water column | 30 days | no leakage |

| Volume consistency | cube 10 x 10cm | no change |

| Temperature Cycles, -20°C tot +40°C | 10 consecutive cycles | no leakage |

| Vibration test 10 Hz/amplitude 3mm | 240 hours | no leakage |

| Axial tensile force | diameter x 10 N | no leakage |

| Resistance to bending | cables 45° in 2 directions >250mm | no leakage |

| Expansion polyurethane foam in pipe | cm | < 40 |

| Chemical resistance |

| 0,1N Na₂SO₄: 30 days - no degradation |

| 0,1N NaCl: 30 days - no degradation |

| 0,1N H₂SO₄: 30 days - no degradation |

| 0,1N NaOH: 30 days - no degradation |

| Diesel: 30 days - no degradation |

| Gasoline: 30 days - no degradation |

| Resistance |

| Moulds: good |

| Rodents: good |

| Shelf life: months - minimal 30 |