Snake Tray’s Mega Snake®: A cut above all wire basket trays

Snake Tray’s 801 Series Mega Snake® Cable Tray is a cut above all other wire basket trays precisely because there is no cutting required. The Mega Snake wire basket tray is a high capacity, pre-configured cable tray system that is a strong as a steel ladder but infinitely more versatile to dramatically reduce installation costs.

Mega Snake allows technicians to complete installations faster by eliminating labor-intensive on-site fabrication and mounting parts required by all other cable tray systems, which keeps more dollars in your pocket on every job.

Whether your next project is building or renovating a data center, medical center, distribution center, or convention center. Whether running data or power cables, indoors or out, your next cable management solution should be centered on Mega Snake. Here’s 7 reasons why:

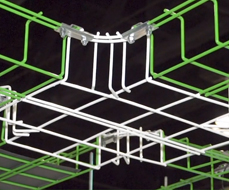

1. Pre-manufactured turns, TEE’s, crosses, and reducers eliminate hours of labor-intensive fabrication on siteWith Mega Snake there is no cutting, no grinding, no waste. Easily navigate changes in direction, elevation, capacity, or route cables around obstacles. Simply, install a prefabricated turn in 5 minutes instead of taking 60 minutes to build each one. |

|

|

|

|

2. Wire basket tray strong as a steel ladder, yet lightweight with an equal load capacityMega Snake is constructed from quarter-inch galvanized steel wire, the largest diameter in the industry, supporting loads up to 150 pounds per linear foot at a fraction of a ladder’s weight and cost. |

|

|

|

|

3. Built-in suspension system eliminates costly brackets and strutsMega Snake’s patented dual-rod Snake Rail accepts standard threaded rods at any position for fast and easy mounting without specialized hardware. Plus, Mega Snake’s low profile design occupies less ceiling space. |

|

|

|

|

4. Connect basket tray sections together in less than a minuteMega Snake uses a single inline splice kit to maintain a continuous mechanical and electrical bond throughout the system. |

|

|

|

|

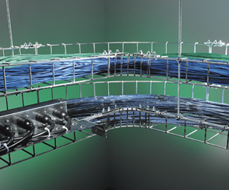

5. Patented side rail systemMega Snake allows for easy attachment of accessories such as power modules, conduit plates, cable dropouts, wireless access points, cameras, and other devices at any point along the run without impinging on cable load capacity. |

|

|

|

|

6. Wire basket tray available in multiple finishesMega Snake can be powder coated to match the décor of environments when left exposed indoors or, choose a stainless steel finish for use in outdoor applications such as rooftop solar arrays. |

|

|

|

|

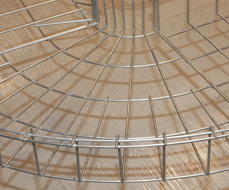

7. Trays nest together for compact and cost effective shipping and material handlingMega Snake’s unique stackable design fits more trays on every pallet to save on transportation costs. It uses less packaging materials for less waste, and makes handling easier for installers on the job site. |

|

Add it all up and it’s easy to see why the Snake Tray Mega Snake is a cut above all other wire basket trays. Electrical contractors and installers using Mega Snake will realize significant savings because it installs faster, is stronger, has greater capacity, needs no on-site fabrication, and requires far fewer parts and accessory pieces than generic wire mesh cable trays to assemble and hang.

Mega Snake 801 Series – Cable Tray Mega Snake 801 Series – Accessories

Mega Snake. Centered on efficiency.