Steel Wire Armoured Cable: All you need to know

SWA Cable (Steel Wire Armoured Cable) is a hard-wearing power cable designed for the supply of mains power. Or to quote most electricians… a pain in the ar… neck!

SPOILER ALERT: A SWA Stripping Tool for Electricians, Engineers, Contractors, Construction Managers, Project Managers and anyone dealing with Steel Wire Armoured Cable at the end of this post.

What is SWA Cable?

SWA is a power and auxiliary control cable, designed for use in the mains supply of electricity. It is one of the various protection electrical links – including 11 kV Cable and 33 kV Cable.

Manufacturers design Steel Wire Armoured Cable with mechanical protection, making it a popular choice for outdoor and underground applications. The armour reduces any risk of pinching or cable damage, while the steel protects the armoured cable. SWA cables are heavy, which makes them extremely difficult to bend. Installers use them primarily for underground installation or to secure cables to outdoor walls using cable cleats.

Other widely used terms for this cable type are: Mains Cable, Armoured Cable, Booklet Armoured Cable and Power Cable. The name Power Cable though, applies to a large variety of links including 6381Y, 6491X, NYCY, NYY-J Cable.

(Quick note for our American audience: This article uses the British English spelling “Armoured” instead of the American English “Armored.”)

SWA Cable Applications / Industries

You’ll often encounter SWA Armoured Cables across a wide range of sectors, including transmission, power distribution, and the renewable energy industry. They’re also vital components in oil, gas, and petrochemical operations, as well as water treatment facilities and various transport systems.

Within railway infrastructure, for instance, SWA cables are used to deliver power to non-trackside areas, while 33kV and 11kV cables handle power distribution between substations — with 33kV cables preferred for longer distance runs. Beyond these, professionals trust SWA cables for indoor and outdoor applications, cable networks, control systems, underground frameworks, and cable ducting setups.

Using Steel Wire Armoured Cable as Earthing

Using the armour to provide earthing or grounding for the equipment connected by the cable is a topic of ongoing debate within the electrical industry. Technicians refer to this function as the circuit protective conductor, or CPC.

Typically, the CPC is provided by an additional core within the cable – for example, using a three-core cable instead of a two-core (line and neutral) with the armouring serving as the CPC – or by an external earth wire running alongside the cable. The main concerns are:

- The relative conductivity of the armouring compared to the cores (which decreases as the size of the cable increases)

- Reliability and Health & Safety issues

According to recent articles and research by authoritative sources, a detailed analysis of the practice concluded that, in most cases, the armouring is suitable to serve as the CPC under UK Wiring Regulations.

Read our Blog Post on: What is Earthing?

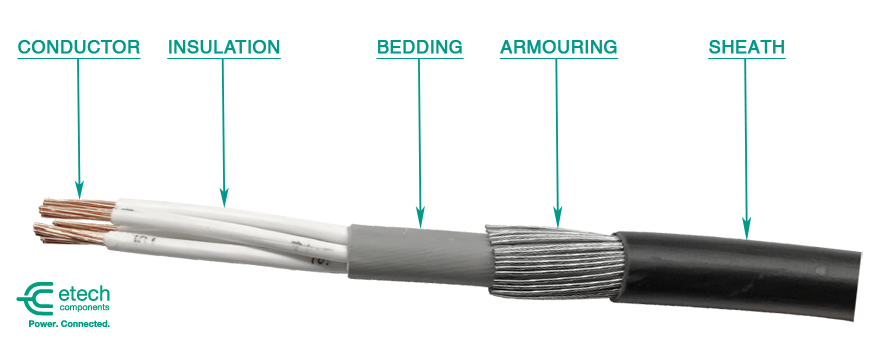

SWA Cable Components

The typical construction of a Steel Wire Armoured Cable includes:

-

Conductor: Class 2 Plain Stranded Copper (Cu) Conductor, complying with BS EN 60228:2005.

-

Insulation: Cross-Linked Polyethylene’s (XLPE) use as insulation in many power cables offers excellent electrical properties and water resistance. It also ensures that conductors and other metal substances do not come into contact with each other.

-

Bedding: Polyvinyl Chloride’s (PVC) choice as bedding provides a protective boundary between inner and outer layers of the cable.

-

Armouring: Steel Wire Armour (SWA) used for mechanical protection. That way the cable can withstand higher stresses, be buried directly and used in external or underground projects. The armouring usually connects to earth and can be used as the CPC (as above).

-

Sheath: Polyvinyl Chloride (PVC) Sheath holds all the components together and provides additional protection from external damage.

The construction of a Steel Wire Armoured Cable depends on its intended use. For example, when the power cable needs to be installed in a highly populated and/or enclosed public area, a Low Smoke Zero Halogen (LSZH) equivalent – called SWA BS 6724 Cable – must be used (SWA Cable BS6724 has a LSZH bedding and a black LSZH sheath). After the King’s Cross fire in London in 1987, which caused fatalities due to toxic gas and smoke inhalation, authorities now require all London Underground cables to use LSZH sheathing.

What Do BS5467 and BS6724 Stand For?

When it comes to safeguarding mains electrical connections in tough conditions, using dependable SWA cables is vital. In the UK, choosing SWA cables that are BASEC certified to the BS5467 standard ensures you get a product that has passed rigorous testing and quality checks. The British Approvals Service for Cables (BASEC) awards this certification to cables that comply fully with its demanding standards.

Specifically, BS5467 covers low voltage SWA cables with EPR or XLPE insulation and a PVC sheath, confirming they meet British construction and testing requirements. Because cable standards can differ across countries, it’s important to verify that you’re selecting the correct armoured cable specification and standards for your particular project.

Cores

Multi Core

Steel Wire Armour is used exclusively on Multi Core Cables, which contain two or more cores:

2-Core SWA Armoured Cable carries live and neutral conductors for Class II and Double-Insulated appliances that do not require an earth connection.

3-Core SWA Armoured Cables include live, neutral and earth conductors, unlike 2-core cables. Three-core cables are designed for Class I or Single-Insulated appliances, which require an earth connection.

4-Core SWA Armoured Cable is ideal for low voltage or low current signal applications. It consists of four individually colour-coded copper conductors, which is why it’s called a four-core cable.

5-Core SWA Armoured Cable is most commonly used for low-voltage transmissions and typically features a three-phase line along with a one zero line for the power supply.

7-Core The primary purpose of SWA Armoured Cable is for low-voltage connections, typically up to a maximum of 50V DC. Each core consists of copper conductors enclosed within the steel armouring.

Single Core (Aluminium Wire Armoured)

Steel wire armour is only suitable for use on multi core versions of the cable. When a cable has only one core, the use of aluminium wire armour (AWA) instead of steel wire is preferable. Electricians should not use single-core cables armoured with steel wire or steel tape in AC circuits. This is because aluminium is non-magnetic, while the steel wire or steel tape armour of a single-core cable is regarded as a ferromagnetic enclosure. For single-core armoured cables, consider using aluminium armour.

SWA Cable vs AWA Cable – Comparison Table

| Feature | Multi Core Cable (Steel Wire Armoured) | Single Core Cable (Aluminium Wire Armoured) |

| Armour Type | Steel Wire Armour (SWA) used exclusively | Aluminium Wire Armour (AWA) preferred over steel for single core |

| Number of Cores | Two or more cores (2-core, 3-core, 4-core, 5-core, 7-core, etc.) | Single core |

| Typical Applications | – 2-Core: Live and neutral for Class II/double-insulated appliances – 3-Core: Live, neutral, earth for Class I/single-insulated appliances – 4-Core: Low voltage/low current signals – 5+ Core: Low-voltage transmission, often 3-phase + neutral – 7-Core: Low-voltage connections up to 50V DC |

Used for AC circuits where single-core conductors are required |

| Earth/Protective Conductor | Included in 3-core and higher versions | Not applicable in armour; earth connection handled differently |

| Magnetic Properties of Armour | Steel wire armour is ferromagnetic | Aluminium armour is non-magnetic, which is important for AC circuits |

| Usage Note | Suitable for use in AC circuits with multiple cores | Steel wire armour on single-core cables is not recommended for AC due to magnetic effects |

Major Challenges of Cutting and Stripping SWA Cable

Cutting and stripping Steel Wire Armoured (SWA) cable presents several challenges. Particularly, the toughness of the steel armour that requires specialised tools to avoid damaging the inner conductors. The process can be time-consuming and risky, as improper handling may cause injury or compromise cable integrity. Additionally, removing the armour cleanly without deforming the cable and ensuring a reliable earth connection are critical but tricky steps. Using the right techniques and swa stripping tools is essential for safety and efficiency.

How to Install and Lay SWA Cable with Confidence

When installing armoured cable underground, it’s crucial to bury the cable deep enough to prevent any damage or disruption. If achieving adequate depth isn’t feasible, you should either increase the burial depth or add extra protective measures to safeguard the cable.

While BS7671 doesn’t specify a fixed minimum depth, best practice recommends installing cables at least 450 mm below ground level to avoid common disturbances. In areas with a higher risk of interference, extend this depth to 600 mm.

For direct burial, surrounding the cable with sharp sand provides a protective layer that guards the sheath and insulation from harm. Additionally, placing an electrical warning tape above the sand alerts anyone digging that a cable lies beneath. Alternatively, when running the cable through conduit, ensure the pipe is completely sealed to keep out moisture.

It’s also essential to properly earth the SWA cable, whether or not the armouring itself serves as the protective conductor. This is vital to meet Automation Disconnection of Supply (ADS) standards and avoid potentially hazardous faults.

Never underestimate the importance of thorough testing after installation. Only a qualified electrician should carry out comprehensive safety and compliance checks to guarantee a secure and reliable connection.

How to Cut & Strip SWA Cable Easily and Safely with the SACS Tool

The rising number of injuries among electricians working with SWA cable, combined with updated Health and Safety Regulations, led most major contractors to ban blades and cable knives on site. This created an urgent need for a new, safer SWA stripping tool. The SACS Tool (SWA Cable Stripper) was a welcome breath of fresh air to tackle this issue while countering all the drawbacks of previous cutting and stripping tools:

Invented by Martin Barrett, an electrician with 30 years’ experience, the SACS Tool makes stripping SWA cable safe and easy – just follow these 5 simple steps:

|

STEP 1 Place tool on the cable at gland point and advance cutting wheel down into the outer insulation. Rotate the tool around the cable to cut through outer insulation. Continue to advance cutting wheel into steel strands to required depth. Repeat insulation only cut approx 2” further along the cable. |

|

STEP 2 Rotate tool 90 degrees to cable at first cut point and advance cutting wheel down into insulation. Guide the tool down the length of the cable ensuring sufficient cut depth. Adjustment of cutting wheel depth as required to cut insulation. |

|

STEP 3 Split and remove outer insulation sheath. Unwind the steel strands and snap using fingertip pressure at cut point. Remove second portion of insulation and splay strands. |

|

STEP 4 Place tool on cable where secondary insulation needs removing. Advance cutting wheel and perform rotary cut to required depth. Care should be taken not to overcut as damage may be caused to conductors. |

|

STEP 5 Rotate tool 90 degrees to cable and advance cutting wheel into insulation. Guide the tool down the length of the cable ensuring sufficient cut depth. Split secondary insulation layer and remove to expose conductors. |

Frequently Asked Questions

Where are SWA cables typically used?

They’re common in underground power, outdoor systems, industrial sites, and railways needing tough cable protection.

Can electricians use the steel armour as the earth conductor?

Sometimes electricians use the steel armour as the earth conductor, but often they need a separate earth core or wire to meet safety standards.

How do SWA and AWA cables differ?

SWA uses steel armour for multi-core cables; AWA uses aluminium armour for single-core cables to reduce magnetic interference.

What’s the recommended burial depth for SWA cables?

Generally, at least 450mm underground, deeper or with extra protection in high-risk areas.

Why is cutting and stripping SWA cables challenging?

The strong steel armour requires special SWA stripping tools to avoid damage and injury, making it harder than stripping regular cables. Using a modern SWA cable stripper like the SACS Tool makes it easier and safer.

Follow these links for more Blog Posts on: Tooling, Standards & Regulations.