Why Regular Crimping Tool Calibration Is Non-Negotiable

Introduction: Crimping Tool Calibration & Why It Matters

Crimping Tool Calibration is vital to ensure safe, consistent and compliant electrical installations. More importantly, British installation standards BS7609 and BS7727 require that crimping tools are calibrated at least every 12 months — or every 6 months if the tool is in constant use. If your tool isn’t calibrated within these timeframes, it’s automatically non-compliant, and so is the installation it’s used on. Whether you’re working with mechanical, hydraulic or battery-operated tools, maintaining tool performance through routine calibration and crimp testing is essential for every installer and engineer. Yet, some overlook calibration — especially when tools seem to be working “just fine”. The risk? Even slight calibration drift can lead to failed terminations, safety hazards, costly downtime and worst of all — a breach of compliance that could invalidate certifications or insurance. In this article, we break down the importance of Crimper Calibration Services, explore best practices for Crimping Tool Maintenance & Repair and explain how E-Tech Components can help you meet and prove compliance.

Crimping Tool Calibration is vital to ensure safe, consistent and compliant electrical installations. More importantly, British installation standards BS7609 and BS7727 require that crimping tools are calibrated at least every 12 months — or every 6 months if the tool is in constant use. If your tool isn’t calibrated within these timeframes, it’s automatically non-compliant, and so is the installation it’s used on. Whether you’re working with mechanical, hydraulic or battery-operated tools, maintaining tool performance through routine calibration and crimp testing is essential for every installer and engineer. Yet, some overlook calibration — especially when tools seem to be working “just fine”. The risk? Even slight calibration drift can lead to failed terminations, safety hazards, costly downtime and worst of all — a breach of compliance that could invalidate certifications or insurance. In this article, we break down the importance of Crimper Calibration Services, explore best practices for Crimping Tool Maintenance & Repair and explain how E-Tech Components can help you meet and prove compliance.

What Is Crimping Tool Calibration?

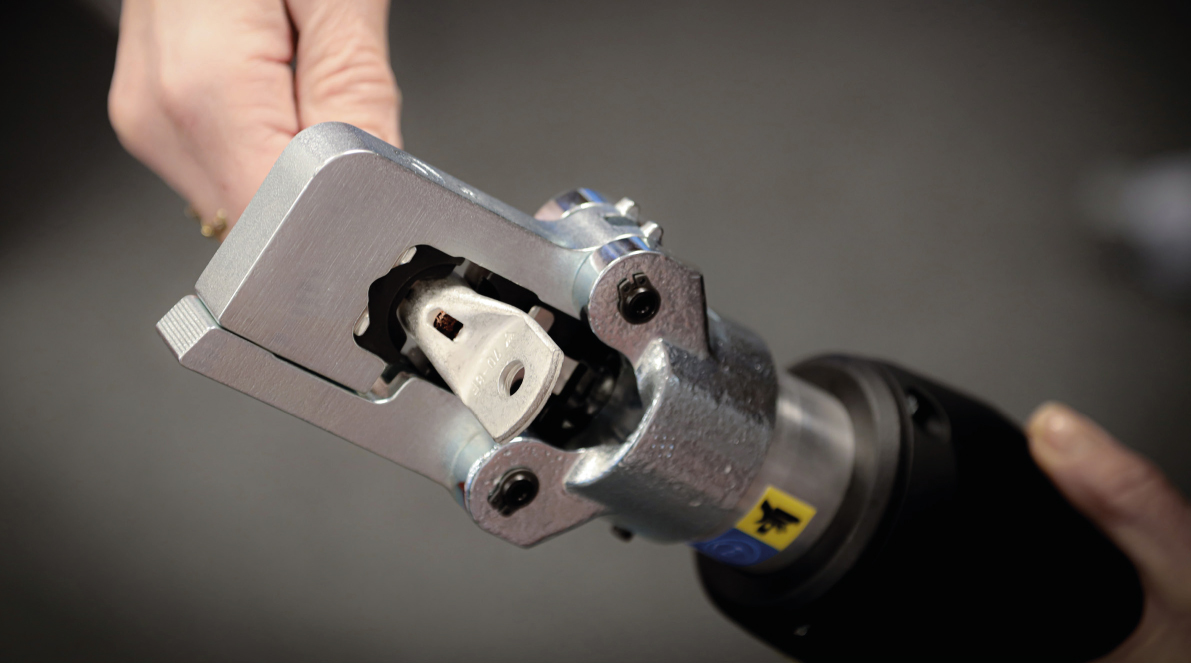

Crimper Calibration is the process of inspecting and adjusting crimp tools to ensure they deliver consistent force, pressure and alignment during operation. Calibration is essential for maintaining crimp tool accuracy and meeting legally recognised installation standards such as BS7609 and BS7727, which define the calibration intervals required for compliance.

Even newly purchased tools can be slightly out of specification. That’s why we ensure your tools are calibrated before dispatching them to you for their first use — to set a performance benchmark from day one.

For many contractors, calibration isn’t an afterthought since it’s built into everyday workflows. On any typical site, every tool must be calibrated to meet Health and Safety Executive (HSE) requirements. Managing these schedules can be a significant task, especially for larger companies, which is why some have computerised systems to track calibration. Including crimp tools in these systems ensures nothing slips through the cracks and helps teams maintain compliance effortlessly.

Do Crimp Tools Need Calibration?

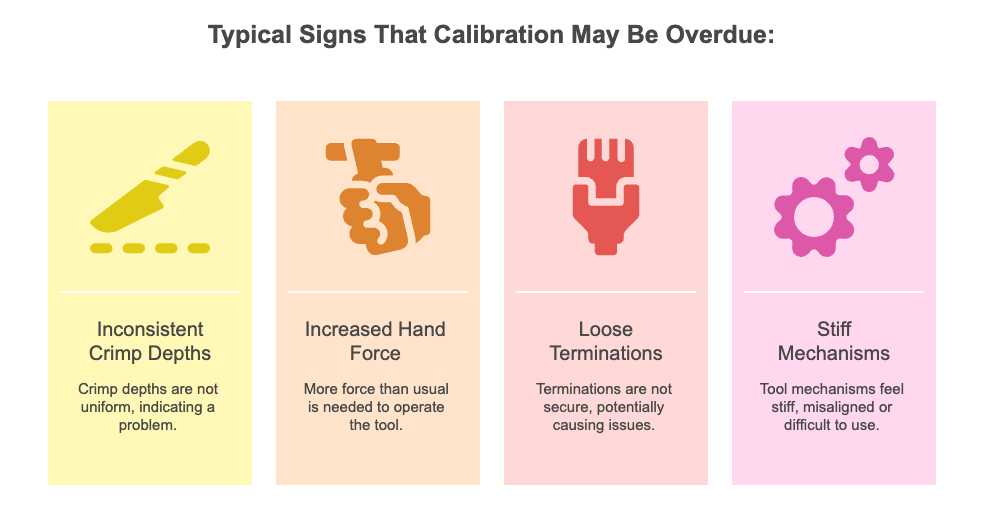

Yes — absolutely! Over time, all crimping tools experience wear and tear. After a certain number of crimps, misalignment, worn jaws or pressure loss can degrade the quality of your crimped connection. Sometimes, these changes are difficult to see, but they can have a serious impact on performance and immediately put you out of compliance with BS7609 / BS7727 if the calibration interval has lapsed.

Routine Crimp Tool Calibration Services help you identify these issues early on — before they lead to installation failure or compliance breaches.

The Risks of Using Uncalibrated Crimp Tools

1. Loose Crimps and Unsafe Connections

A poorly calibrated crimping tool can result in incorrect compaction of the terminal, leaving air gaps inside the crimp. This increases electrical resistance, which leads to overheating and, in some cases, fire. Loose crimps also reduce mechanical strength, increasing the risk of cable pullout.

2. Reduced Tool Life

Uncalibrated tools often experience uneven stress, which leads to premature wear. Regular calibration helps extend their lifespan and saves you from unnecessary replacement costs.

3. Increased Risk of Repetitive Strain Injury (RSI)

Poor tool alignment or excessive force requirements can increase strain on the installer. Over time, this can cause fatigue or RSI.

4. Non-Compliance with Industry Standards

Certain industries — including rail and marine — require documented Crimp Tool Calibration Procedures to meet legal or regulatory frameworks. More broadly, BS7609 and BS7727 make it clear — calibration must be carried out every 12 months, or every 6 months for high-use tools. Fail to do this, and the tool — and every installation it’s used for — will be non-compliant.

What are the Benefits of Regular Crimp Tool Calibration?

Reliable Electrical Terminations

Reliable Electrical Terminations

When your tools are properly calibrated, crimped connections are mechanically strong, electrically sound and fully compliant with industry standards. This reduces the need for rework and crimping tool maintenance.

Improved Tool Performance

Routine Crimp Tool Testing and adjustments help maintain peak crimping tool performance. Calibrated tools operate more smoothly and require less force — making installations faster and more ergonomic.

Longer Tool Lifespan

Crimping tools are a long-term investment. Calibration ensures that wear is detected and corrected early, extending tool longevity and improving cost-efficiency.

Reduced Downtime

Avoiding unexpected tool failures keeps your projects on track and minimises unplanned crimping tool maintenance or replacement.

Enhanced Reputation and Professionalism

Nowadays, clients and contractors increasingly demand traceability and quality assurance. By using a Crimping Tool Calibration Service, you’re demonstrating your commitment to safety, compliance and best practice. Ultimately, a calibration certification shows that you meet BS7609 and BS7727 requirements.

E-Tech Components: Authorised Elpress Service Centre

As an Authorised Elpress Service Centre, E-Tech Components provides expert Crimping Tool Calibration, inspection and servicing. Whether you’re using battery, hydraulic or mechanical tools, our service covers:

As an Authorised Elpress Service Centre, E-Tech Components provides expert Crimping Tool Calibration, inspection and servicing. Whether you’re using battery, hydraulic or mechanical tools, our service covers:

- Full Crimp Tool Inspection and diagnostic crimp testing

- Manufacturer-approved Crimp Tool Adjustment and repair

- Crimper calibration to meet the latest standards

- Certification and documentation for your records

- Quick turnaround and nationwide service

We also offer guidance on the Crimp Tool Calibration Procedure and how to schedule regular checks as part of your Crimping Tool Maintenance plan.

How Often Should You Calibrate?

How Often Should You Calibrate?

According to BS7609 and BS7727, you must calibrate your crimping tools:

- Every 12 months for standard-use tools

- Every 6 months if the tool is in constant use

- After repairs or mechanical damage

- Before critical installation work

- After failed crimp testing

These intervals are not just best practice — they’re important for compliance. Missing them means the tool is not conforming to the standard, and neither is the installation.

Crimp Tool Repair and Servicing

In addition to calibration, we offer full Crimping Tool Repair Services. If your tool is showing signs of wear, don’t replace it — repair it. We’ll assess its condition, carry out adjustments and restore it to full working order.

To return tools for service, repair or calibration, visit our website to download our Return Form. After completing yours, make sure to include it with your equipment.

Conclusion: Calibration is Not Optional – It’s Essential!

When it comes to electrical terminations, small mistakes can have big consequences. Crimping Tool Calibration isn’t just good practice — it’s a requirement under BS7609 and BS7727. It’s non-negotiable, because the standards say so. From reducing fire risk to maintaining compliance and tool longevity, the benefits far outweigh the effort.

Whether you’re an installer, engineer or procurement manager, prioritising Crimp Tool Calibration Services is one of the smartest moves you can make for safety, consistency and reliability. Ultimately, calibration ensures that your installations remain legally compliant.

Need Support?

Contact our team today for crimp testing, crimper calibration bookings or tool inspections: