Elpress Deep Earthing System

Product overview

Elpress Deep Earthing System

The Elpress Deep Earthing System consists of five parts: (elpress fs11, fs31)

- Hardened Steel Tip

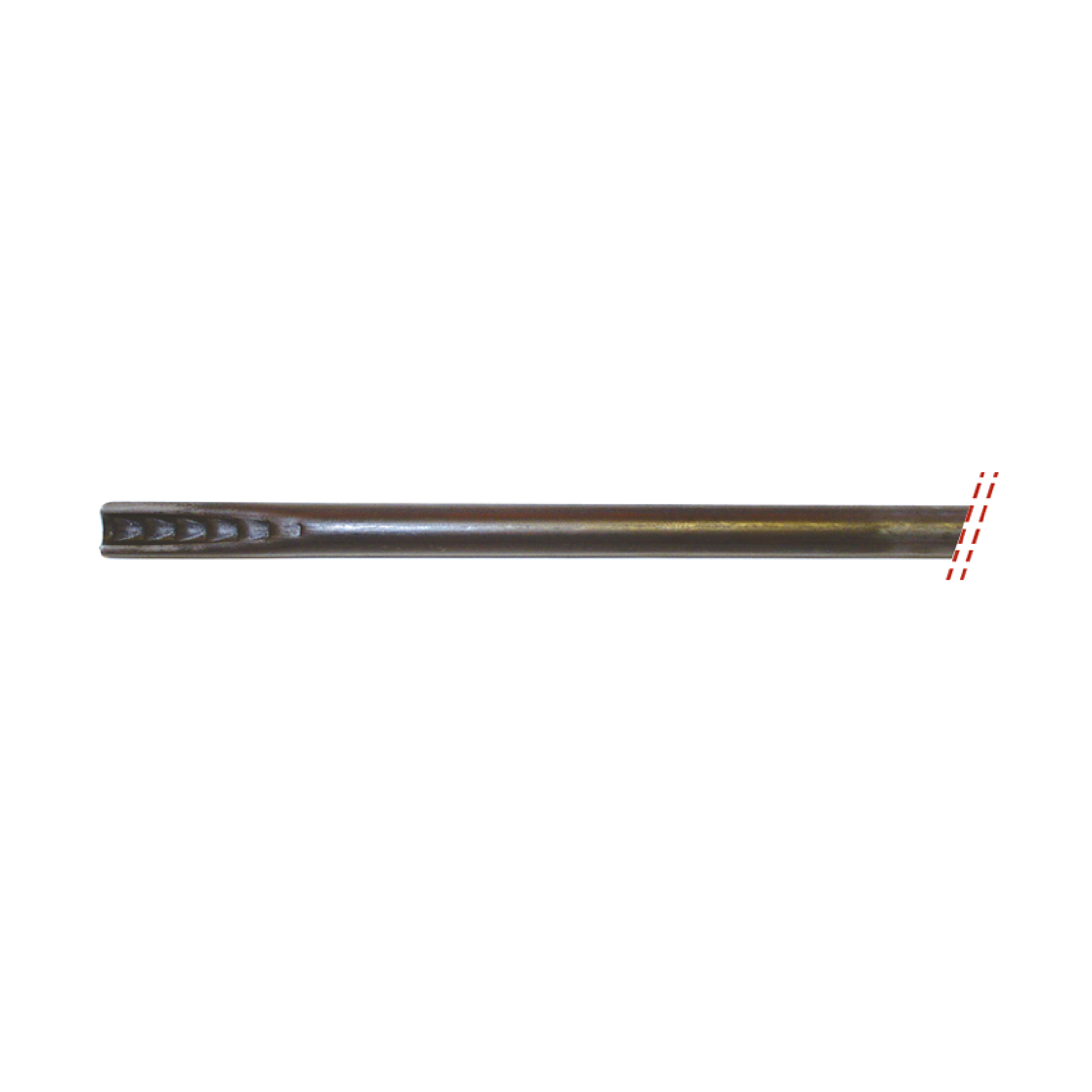

- Leading Rod

- Extensions Rods

- Driving Studs or Sleeves

- Earthing Wire (supplied by wholesalers)

You can find more information on the Power Hammer to drive down studs (or sleeves) here: Elpress Power Hammer for Deep Earthing System.

General Information

SIMPLE FUNCTION

The earthing wire is inserted into and held by the steel tip. The extension rods have guiding pins to enter into the previous tube end to form a stable extension of the system. By monitoring the earthing resistance, installer can interrupt the driving down at best point.

EARTHING

An earth electrode is a conductor in the soil with the purpose of discharging electrical current from a connected facility. The use of electricity with bad earthing includes a high risk. All suppliers of power must have approved earth electrodes at their facilities. It means that flash-over voltages, which can appear for different reasons are led into the soil so they do not cause any damages and/ or injuries. Earthing serves as, among other things, person protection, property protections, Electro Magnetic Pulses protection, lightning protection and similar.

PRINCIPAL DESIGN

The Elpress Deep Earthing concept is a system without extra connection points. The earthing electrode is a copper wire which is pulled down by means of 0.8 m steel tubes (“rods”). A hardened steel tip locks the Cu wire into the leading rod. For each extension rod the wire is pulled a further 0.8 m down alongside the rods. As you can monitor the earthing resistance continuously at the other end of the wire, you can stop the driving down when reaching a satisfactory low resistance. Installer pulls up the top extension rod and reuses is. Drive down normally takes place with Elpress Power Hammer for Deep Earthing with a suitable driving stud or with a sledge hammer and the driving cap FS61 or FS62C.

For more information on Elpress Deep Earthing System (FS11, FS12, FS21, FS31 etc.), consult PDF File or Technical Data Table below.

*Technical Data subject to change without notice.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Interested in this Product?

+44 (0)1744 762 929Technical Data

| Cat. No. | Description | Area | Ø | Pcs/ Pack | Weight | Dimensions | Used for | To be used with | |

|

FS11 | Steel tip with hardened top. | 16-70 mm2 | 5 | 0.9 kg/pack | 135 mm | FS21 leading rod | ||

|

FS12 | Steel tip with hardened top. | 70-150 mm2 | 5 | 1.3 kg/pack | 135 mm | FS21 leading rod | ||

|

FS21 | Leading rod, with a knurled recess for effective locking of earth conductor. | 17 mm | 5 | 3.3 kg/pack | 800 mm | Normal and soft soils. | ||

|

FS31 | Extension Rod with locating pin fitting into the preceeding tube. | 17 mm | 5 | 3.9 kg/pack | 870 mm (incl guiding pin) | Normal and soft soils. | FS21 leading rod | |

|

FSHD11 | Heavy Duty Special Steel Tip with hardened top. | 25-150 mm2 | 5 | 1.3 kg/pack | 153 mm | Hard and stony soils. | FSHD23 leading rod | |

|

FSHD23 | Heavy Duty Leading Rod, with a knurled recess for effective locking of the earthing wire. | 21 mm | 5 | 5.5 kg/pack | 800 mm | Hard and stony soils. | FSHD11 tip | |

|

FSHD31 | Heavy Duty Extension Rod, with guiding pin that fits into the preceding tube. | 21 mm | 5 | 6.2 kg/pack | 870 mm (incl guiding pin) | Hard and stony soils. | ||

|

FS41 | Withdrawal Handle to pull up the top extension rod for re-use. | Ø 18.5 mm and Ø 22.5 mm | 1 | 0.42 kg | 230 x 60 mm | FS & FSHD type rods | ||

|

FS62C | Driving Sleeve used when driving the rods down with a sledge hammer. | 1 | 1.0 kg | 110 x 45 mm | FS21 & FS31 rods | |||

|

FS61 | Driving Cap used when driving the FS21 and FS31 rods down with a sledge hammer. | 1 | 0.15 kg | 58 x 22 mm | FS21 & FS31 rods | |||

|

FSHD62C | Driving Sleeve used when driving the FSHD type rods down with a sledge hammer. | 1 | 1.0 kg/pack | 110 x 45 mm | FSHD type rods | |||