Elpress KRD Copper Cable Lugs (16-1000mm²)

Product overview

Elpress KRD Copper Cable Lugs

Elpress KRD Copper Cable Lugs (16-1000mm²) are produced from electrolytic copper and are tin plated and are suitable for Stranded (Class 2) Cu Conductors.

Part Numbers: KRD16-5, KRD16-6, KRD16-8, KRD16-10, KRD16-12, KRD25-00, KRD25-6, KRD25-8, KRD25-10, KRD25-12, KRD35-00, KRD35-6, KRD35-8, KRD35-10, KRD35-12, KRD35-14, KRD35-16, KRD50-6, KRD50-8, KRD50-10, KRD50-12, KRD50-16, KRD70-00, KRD70-7, KRD70-8, KRD70-10, KRD70-12, KRD70-16, KRD95-00, KRD95-6, KRD95-8, KRD95-10, KRD95-12, KRD95-14, KRD95-16, KRD120-00, KRD120-8, KRD120-10, KRD120-12, KRD120-14, KRD120-16, KRD120-20, KRD150-00, KRD150-8, KRD150-10, KRD150-12, KRD150-14, KRD150-16, KRD150-20, KRD185-00, KRD185-8, KRD185-10, KRD185-12, KRD185-14, KRD185-16, KRD185-20, KRD240-00, KRD240-10, KRD240-12, KRD240-16, KRD240-20, KRD300-00, KRD300-10, KRD300-12, KRD300-14, KRD300-16, KRD300-20, KRD300-24, KRD400-00, KRD400-12, KRD400-14, KRD400-16, KRD400-24, KRD400-20, KRD500-00, KRD500-12, KRD500-14, KRD500-16, KRD500-20, KRD500-24, KRD630-00, KRD630-12, KRD630-16, KRD630-18, KRD630-20, KRD630-24, KRD800-00, KRD800-16, KRD800-24, KRD1000-00, KRD1000-20, KRD1000-24.

General Information

SYSTEM ELPRESS

System Elpress consists of Terminals and Tools designed and tested together to give a certified crimping result. This ensures that users will feel confident when using our systems, and the achievement of a secure connection through the proper handling of our products. By using Elpress Cu-Connection elements together with one of Elpress Crimp Systems one obtains a connection that has been tested according to the requirements of IEC 61238:1.

COPPER (CU) TERMINALS

Elpress Copper Connectors made of pure Copper 99.95%. We manufacture Tube Terminals type KR/ KRF/ KRD/ KRT, Through Connectors type KS/ KSF/ KSD/ KST for stranded conductors, IEC 60228 Class 2, and flexible conductors IEC 60228 Class 5 such as C-Sleeves primarily pre-splicing of Cu-lines and many customised products. For flexible and stranded Cu conductors, use terminals of type KR/ KRF and through connectors of type KS/ KSF. Terminals type KRD/ KRT and through connectors type KSD/ KST are normally used for stranded Cu conductors from and including 500mm2. Mainly use terminals of type KR/ KRF/ KRD/ KRT in the splicing of copper conductors in cable assemblies. Can also use them for straight splicing of earth conductors. With a branching sleeve, type C, one splices and branches earth conductors, lightning conductor installations and the like.

Approvals & Marking

UL-APPROVED TERMINALS

UL is an American, but also internationally accepted, standard. Elpress standard Cu Terminals of types KR/ KS, KRF/ KSF, KRT/ KST, KRFS, KRFN are UL-approved according to file no E205350.

DNV APPROVED

Elpress KR/ KS, KRF/ KSF and KRT/ KST Terminals meet DNV’s rules for classification of ships and Det Norske Veritas’ Offshore Standards. The Terminals have an approval for installations on ships and mobile offshore units.

NUMBER OF CRIMPS

Normally one crimp is necessary up to and including 150mm2 and 2 or 3 crimps for larger areas. Note, however, that another number of crimps may be essential in some cases, see table for tool dies. If possible, you should place crimps next to each other with a couple of mm spacing between each one. Overlap is sometimes inevitable.

MARKING OF CU TERMINALS

Elpress marking system for Copper Terminals shows logotype, cable area and type number for hexagonal die. This system allows you to check if you are using the correct tools when contact crimping. The die number automatically becomes embossed during the contact crimping.

For more information on Elpress KRD Copper Cable Lugs – for Stranded Cable (KRD16-6, KRD16-12, KRD35-8, KRD185-12), consult PDF File or Technical Data Table below. KRD16-6, KRD35-8

*Technical Data subject to change without notice.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Interested in this Product?

+44 (0)1744 762 929Technical Data

- Material: Cu 99.95%, tin plated Cu/Sn.

- Inspection hole

- For Stranded (Class 2) Cu conductors.

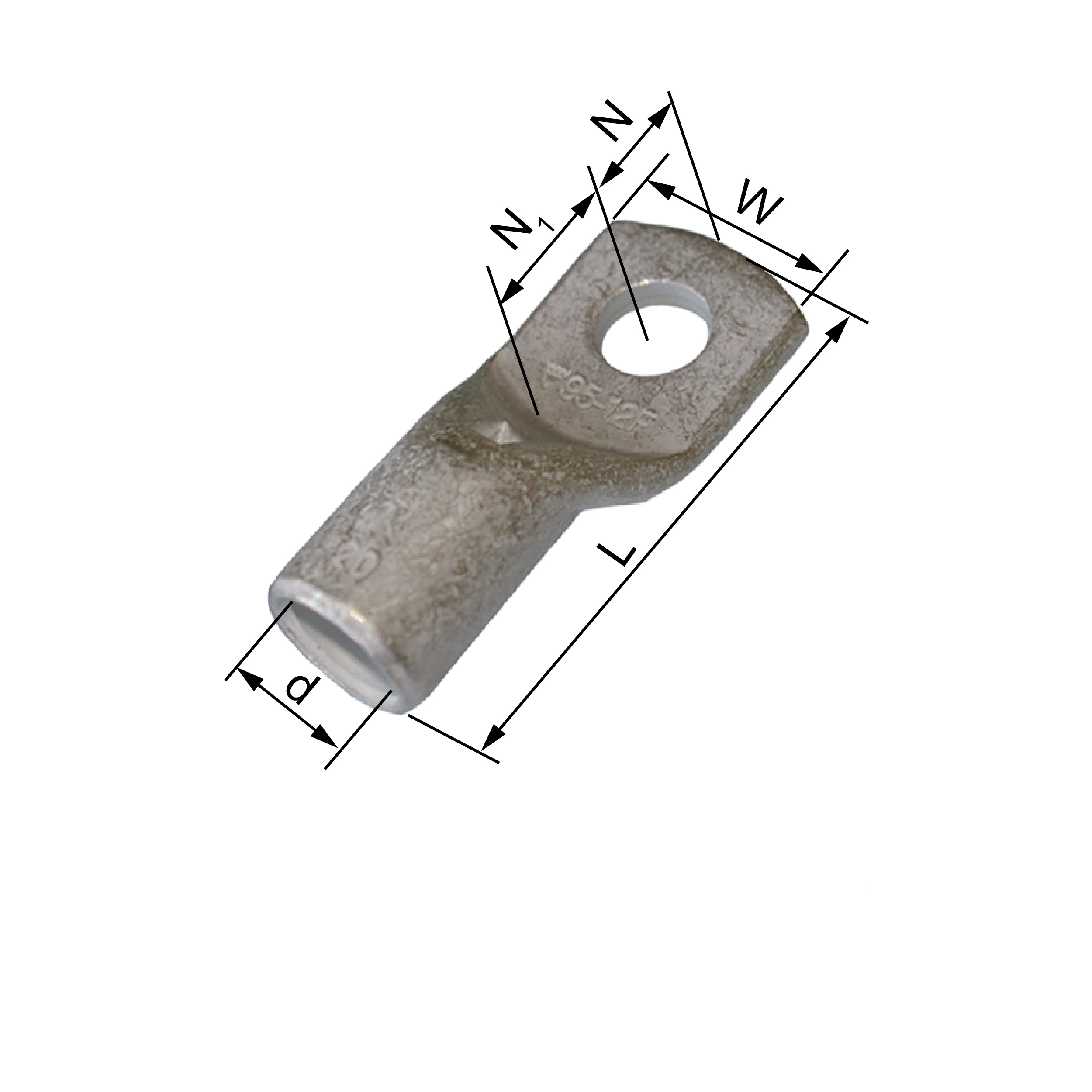

| Cat. No. | Area mm² | AWG | d | D | N | N1 | L | W | s | t | Screw | Die no. | Pcs/ Pack | Rec. Tool |

| KRD16-5 | 16 | 6 | 5,4 | 8 | 6 | 8 | 29 | 12 | 10 | 2,5 | 5 | 8 | 100 | PVL350, V600, V1300, V250 |

| KRD16-6 | 16 | 6 | 5,4 | 8 | 6 | 8 | 29 | 12 | 10 | 2,5 | M6 | 8 | 100 | PVL350, V600, V1300, V250 |

| KRD16-8 | 16 | 6 | 5,4 | 8 | 8 | 9 | 33 | 14 | 10 | 2,1 | M8 | 8 | 100 | PVL350, V600, V1300, V250 |

| KRD16-10 | 16 | 6 | 5,4 | 8 | 8 | 10 | 34 | 16 | 10 | 1,8 | M10 | 8 | 100 | PVL350, V600, V1300, V250 |

| KRD16-12 | 16 | 6 | 5,4 | 8 | 10 | 13,5 | 41 | 18 | 10 | 1,6 | M12 | 8 | 100 | PVL350, V600, V1300, V250 |

| KRD25-00 | 25 | 4 | 6,7 | 9 | - | - | 38 | 16 | 10 | 1,8 | - | 9 | 100 | PVL350, V600, V1300, V250 |

| KRD25-6 | 25 | 4 | 6,7 | 9 | 7 | 9 | 32 | 13 | 10 | 2,2 | M6 | 9 | 100 | PVL350, V600, V1300, V250 |

| KRD25-8 | 25 | 4 | 6,7 | 9 | 7 | 9 | 32 | 13 | 10 | 2,2 | M8 | 9 | 100 | PVL350, V600, V1300, V250 |

| KRD25-10 | 25 | 4 | 6,7 | 9 | 10 | 12 | 38 | 16 | 10 | 1,8 | M10 | 9 | 100 | PVL350, V600, V1300, V250 |

| KRD25-12 | 25 | 4 | 6,7 | 9 | 12 | 13 | 47 | 22 | 13 | 1,6 | M12 | 9 | 100 | PVL350, V600, V1300, V250 |

| KRD35-00 | 35 | 2 | 8 | 11 | - | - | 39 | - | - | - | M35 | 11 | 100 | PVL350, V600, V1300, V250 |

| KRD35-6 | 35 | 2 | 8 | 11 | 8 | 10 | 39 | 16 | 13 | 2,9 | M6 | 11 | 100 | PVL350, V600, V1300, V250 |

| KRD35-8 | 35 | 2 | 8 | 11 | 8 | 10 | 39 | 16 | 13 | 2,9 | M8 | 11 | 100 | PVL350, V600, V1300, V250 |

| KRD35-10 | 35 | 2 | 8 | 11 | 10 | 11 | 42 | 17 | 13 | 2,7 | M10 | 11 | 100 | PVL350, V600, V1300, V250 |

| KRD35-12 | 35 | 2 | 8 | 11 | 12 | 13 | 47 | 22 | 13 | 2,1 | M12 | 11 | 100 | PVL350, V600, V1300, V250 |

| KRD35-14 | 35 | 2 | 8 | 11 | 12 | 13 | 47 | 22 | 13 | 2 | M14 | 11 | 100 | PVL350, V600, V1300, V250 |

| KRD35-16 | 35 | 2 | 8 | 11 | 15 | 18 | 56 | 25 | 13 | 1,7 | M16 | 11 | 100 | PVL350, V600, V1300, V250 |

| KRD50-6 | 50 | 1/0 | 9,5 | 12 | 8,5 | 11,5 | 44 | 18 | 16 | 2,4 | M6 | 12 | 100 | PVL350, V600, V1300, V250 |

| KRD50-8 | 50 | 1/0 | 9,5 | 12 | 8,5 | 11,5 | 44 | 18 | 16 | 2,4 | M8 | 12 | 100 | PVL350, V600, V1300, V250 |

| KRD50-10 | 50 | 1/0 | 9,5 | 12 | 9,5 | 11,5 | 49 | 18 | 20 | 2,4 | M10 | 12 | 100 | PVL350, V600, V1300, V250 |

| KRD50-12 | 50 | 1/0 | 9,5 | 12 | 12 | 14 | 53 | 20 | 20 | 2,2 | M12 | 12 | 100 | PVL350, V600, V1300, V250 |

| KRD50-16 | 50 | 1/0 | 9,5 | 12 | 15 | 18 | 60,5 | 23 | 20 | 1,8 | M16 | 12 | 100 | PVL350, V600, V1300, V250 |

| KRD70-00 | 70 | 2/0 | 11,3 | 14 | - | - | 63 | 25 | 23 | 2,2 | - | 14 | 50 | PVL350, V600, V1300, V250 |

| KRD70-7 | 70 | 2/0 | 11,3 | 14 | 11 | 11 | 54 | 22 | 23 | 2,5 | M7 | 14 | 50 | PVL350, V600, V1300, V250 |

| KRD70-8 | 70 | 2/0 | 11,3 | 14 | 11 | 11 | 54 | 22 | 23 | 2,6 | M8 | 14 | 50 | PVL350, V600, V1300, V250 |

| KRD70-10 | 70 | 2/0 | 11,3 | 14 | 11 | 11 | 54 | 22 | 23 | 2,6 | M10 | 14 | 50 | PVL350, V600, V1300, V250 |

| KRD70-12 | 70 | 2/0 | 11,3 | 14 | 12 | 13 | 57 | 22 | 23 | 2,6 | M12 | 14 | 50 | PVL350, V600, V1300, V250 |

| KRD70-16 | 70 | 2/0 | 11,3 | 14 | 15 | 16 | 63 | 25 | 23 | 2,2 | M16 | 14 | 50 | PVL350, V600, V1300, V250 |

| KRD95-00 | 95 | 4/0 | 13 | 16 | - | - | 67 | 28 | 26 | 2,5 | - | 16 | 50 | PVL350, V600, V1300, V250 |

| KRD95-6 | 95 | 4/0 | 13 | 16 | 11 | 11 | 58 | 24 | 26 | 3 | M6 | 16 | 50 | PVL350, V600, V1300, V250 |

| KRD95-8 | 95 | 4/0 | 13 | 16 | 11 | 11 | 58 | 24 | 26 | 2,9 | M8 | 16 | 50 | PVL350, V600, V1300, V250 |

| KRD95-10 | 95 | 4/0 | 13 | 16 | 11 | 11 | 58 | 24 | 26 | 2,9 | M10 | 16 | 50 | PVL350, V600, V1300, V250 |

| KRD95-12 | 95 | 4/0 | 13 | 16 | 12 | 13 | 61 | 24 | 26 | 2,9 | M12 | 16 | 50 | PVL350, V600, V1300, V250 |

| KRD95-14 | 95 | 4/0 | 13 | 16 | 12 | 13 | 61 | 24 | 26 | 2,8 | M14 | 16 | 50 | PVL350, V600, V1300, V250 |

| KRD95-16 | 95 | 4/0 | 13 | 16 | 15 | 16 | 67 | 28 | 26 | 2,5 | M16 | 16 | 50 | PVL350, V600, V1300, V250 |

| KRD120-00 | 120 | 250 | 15 | 19 | - | - | 70 | 28 | 26 | 3,8 | - | 19 | 50 | V600, V1300, V250 |

| KRD120-8 | 120 | 250 | 15 | 19 | 11 | 14 | 64 | 28 | 26 | 3,8 | M8 | 19 | 50 | V600, V1300, V250 |

| KRD120-10 | 120 | 250 | 15 | 19 | 11 | 14 | 64 | 28 | 26 | 3,9 | M10 | 19 | 50 | V600, V1300, V250 |

| KRD120-12 | 120 | 250 | 15 | 19 | 11 | 14 | 64 | 28 | 26 | 3,9 | M12 | 19 | 50 | V600, V1300, V250 |

| KRD120-14 | 120 | 250 | 15 | 19 | 15 | 17 | 70 | 28 | 26 | 4 | M14 | 19 | 50 | V600, V1300, V250 |

| KRD120-16 | 120 | 250 | 15 | 19 | 15 | 16 | 70 | 28 | 26 | 3,9 | M16 | 19 | 50 | V600, V1300, V250 |

| KRD120-20 | 120 | 250 | 15 | 19 | 16,5 | 18,5 | 74 | 30 | 26 | 3,7 | M20 | 19 | 50 | V600, V1300, V250 |

| KRD150-00 | 150 | 300 | 17 | 22 | - | - | 83 | 32 | 30 | 4,8 | - | 22 | 50 | V600, V1300, V250 |

| KRD150-8 | 150 | 300 | 17 | 22 | 15 | 23 | 83 | 32 | 30 | 4,8 | M8 | 22 | 50 | V600, V1300, V250 |

| KRD150-10 | 150 | 300 | 17 | 22 | 15 | 16 | 76 | 32 | 30 | 4,9 | M10 | 22 | 50 | V600, V1300, V250 |

| KRD150-12 | 150 | 300 | 16 | 22 | 15 | 16 | 76 | 32 | 30 | 4,9 | M12 | 22 | 50 | V600, V1300, V250 |

| KRD150-14 | 150 | 300 | 17 | 22 | 15 | 17 | 76 | 32 | 30 | 5 | M14 | 22 | 50 | V600, V1300, V250 |

| KRD150-16 | 150 | 300 | 17 | 22 | 15 | 16 | 76 | 32 | 30 | 4,9 | M16 | 22 | 50 | V600, V1300, V250 |

| KRD150-20 | 150 | 300 | 17 | 22 | 19 | 19 | 83 | 32 | 30 | 4,9 | M20 | 22 | 50 | V600, V1300, V250 |

| KRD185-00 | 185 | 350 | 19 | 25 | - | - | 87 | 36 | 32 | 5,9 | - | 25 | 50 | V600, V1300, V250 |

| KRD185-8 | 185 | 350 | 19 | 25 | 15 | 16 | 80 | 36 | 32 | 5,9 | M8 | 25 | 50 | V600, V1300, V250 |

| KRD185-10 | 185 | 350 | 19 | 25 | 15 | 16 | 80 | 36 | 32 | 5,9 | M10 | 25 | 50 | V600, V1300, V250 |

| KRD185-12 | 185 | 350 | 19 | 25 | 15 | 16 | 80 | 36 | 32 | 5,9 | M12 | 25 | 50 | V600, V1300, V250 |

| KRD185-14 | 185 | 350 | 19 | 25 | 15 | 16 | 80 | 36 | 32 | 5,8 | M14 | 25 | 50 | V600, V1300, V250 |

| KRD185-16 | 185 | 350 | 19 | 25 | 15 | 16 | 80 | 36 | 32 | 5,9 | M16 | 25 | 50 | V600, V1300, V250 |

| KRD185-20 | 185 | 350 | 19 | 25 | 19 | 19 | 87 | 36 | 32 | 5,9 | M20 | 25 | 50 | V600, V1300, V250 |

| KRD240-00 | 240 | 500 | 21 | 27 | - | - | 93 | 39 | 37 | 5,9 | - | 27 | 50 | V1300, V250 |

| KRD240-10 | 240 | 500 | 21 | 27 | 15 | 16 | 86 | 39 | 37 | 5,9 | M10 | 27 | 50 | V1300, V250 |

| KRD240-12 | 240 | 500 | 21 | 27 | 15 | 16 | 86 | 39 | 37 | 5,9 | M12 | 27 | 50 | V1300, V250 |

| KRD240-16 | 240 | 500 | 21 | 27 | 15 | 16 | 86 | 39 | 37 | 5,9 | M16 | 27 | 50 | V1300, V250 |

| KRD240-20 | 240 | 500 | 21 | 27 | 19 | 19 | 93 | 39 | 37 | 5,9 | M20 | 27 | 50 | V1300, V250 |

| KRD300-00 | 300 | 600 | 24 | 30 | - | - | 100 | 44 | 42 | 5,8 | - | 30 | 25 | V1300, V250 |

| KRD300-10 | 300 | 600 | 24 | 30 | 19 | 19 | 100 | 44 | 42 | 5,8 | M10 | 30 | 25 | V1300, V250 |

| KRD300-12 | 300 | 600 | 24 | 30 | 19 | 19 | 100 | 44 | 42 | 5,8 | M12 | 30 | 25 | V1300, V250 |

| KRD300-14 | 300 | 600 | 24 | 30 | 19 | 20 | 100 | 44 | 42 | 6 | M14 | 30 | 25 | V1300, V250 |

| KRD300-16 | 300 | 600 | 24 | 30 | 19 | 19 | 100 | 44 | 42 | 5,8 | M16 | 30 | 25 | V1300, V250 |

| KRD300-20 | 300 | 600 | 24 | 30 | 19 | 19 | 100 | 44 | 42 | 5,8 | M20 | 30 | 25 | V1300, V250 |

| KRD300-24 | 300 | 600 | 24 | 30 | 22 | 24 | 108 | 44 | 42 | 5,8 | M24 | 30 | 25 | V1300, V250 |

| KRD400-00 | 400 | 750 | 26 | 32 | - | - | 116 | 48 | 44 | 5,8 | - | 32 | 25 | V1300, V250 |

| KRD400-12 | 400 | 750 | 26 | 32 | 22 | 31 | 116 | 48 | 44 | 5,8 | M12 | 32 | 25 | V1300, V250 |

| KRD400-14 | 400 | 750 | 26 | 32 | 22 | 31 | 116 | 48 | 44 | 5,8 | M14 | 32 | 25 | V1300, V250 |

| KRD400-16 | 400 | 750 | 26 | 32 | 22 | 31 | 116 | 48 | 44 | 5,8 | M16 | 32 | 25 | V1300, V250 |

| KRD400-24 | 400 | 750 | 26 | 32 | 22 | 31 | 116 | 48 | 44 | 5,8 | M24 | 32 | 25 | V1300, V250 |

| KRD400-20 | 400 | 750 | 26 | 32 | 22 | 31 | 116 | 48 | 44 | 5,8 | M20 | 32 | 25 | V1300, V250 |

| KRD500-00 | 500 | 1000 | 31 | 40 | - | - | 160 | 58 | 70 | 8,8 | - | 40 | 5 | V1470, V250 |

| KRD500-12 | 500 | 1000 | 31 | 40 | 25 | 35 | 150 | 58 | 70 | 8,8 | M12 | 40 | 5 | V1470, V250 |

| KRD500-14 | 500 | 1000 | 31 | 40 | 25 | 35 | 150 | 58 | 70 | 8,8 | M14 | 40 | 5 | V1470, V250 |

| KRD500-16 | 500 | 1000 | 31 | 40 | 25 | 35 | 150 | 58 | 70 | 8,8 | M16 | 40 | 5 | V1470, V250 |

| KRD500-20 | 500 | 1000 | 31 | 40 | 25 | 35 | 150 | 58 | 70 | 8,8 | M20 | 40 | 5 | V1470, V250 |

| KRD500-24 | 500 | 1000 | 31 | 40 | 25 | 35 | 150 | 58 | 70 | 8,8 | M24 | 40 | 5 | V1470, V250 |

| KRD630-00 | 630 | 1250 | 34 | 45 | - | - | 165 | 65 | 70 | 10,8 | - | 45 | 1 | V1470, V250 |

| KRD630-12 | 630 | 1250 | 34 | 45 | 25 | 35 | 150 | 65 | 70 | 10,8 | M12 | 45 | 1 | V1470, V250 |

| KRD630-16 | 630 | 1250 | 34 | 45 | 25 | 35 | 150 | 65 | 70 | 10,8 | M16 | 45 | 1 | V1470, V250 |

| KRD630-18 | 630 | 1250 | 34 | 45 | 25 | 35 | 150 | 65 | 70 | 11 | M18 | 45 | 1 | V1470, V250 |

| KRD630-20 | 630 | 1250 | 34 | 45 | 25 | 35 | 150 | 65 | 70 | 10,8 | M20 | 45 | 1 | V1470, V250 |

| KRD630-24 | 630 | 1250 | 34 | 45 | 25 | 35 | 150 | 65 | 70 | 10,8 | M24 | 45 | 1 | V1470, V250 |

| KRD800-00 | 800 | 1600 | 39 | 53 | - | - | 195 | 75 | 80 | 13,8 | - | 53 | 1 | V1470, V250 |

| KRD800-16 | 800 | 1600 | 39 | 53 | 25 | 35 | 175 | 75 | 80 | 13,8 | M16 | 53 | 1 | V1470, V250 |

| KRD800-24 | 800 | 1600 | 39 | 53 | 35 | 45 | 195 | 75 | 80 | 13,8 | M24 | 53 | 1 | V1470, V250 |

| KRD1000-00 | 1000 | 2000 | 43 | 56 | - | - | 195 | 80 | 80 | 12,8 | - | 56 | 1 | V1470 |

| KRD1000-20 | 1000 | 2000 | 43 | 56 | 35 | 45 | 195 | 80 | 80 | 12,8 | M20 | 56 | 1 | V1470 |

| KRD1000-24 | 1000 | 2000 | 43 | 56 | 35 | 45 | 195 | 80 | 80 | 12,8 | M24 | 56 | 1 | V1470 |

Marking example KRD: 70 10 (Elpress logotype included)

70=mm² 10= palm hole for M10

t= palm thickness, s= strip length