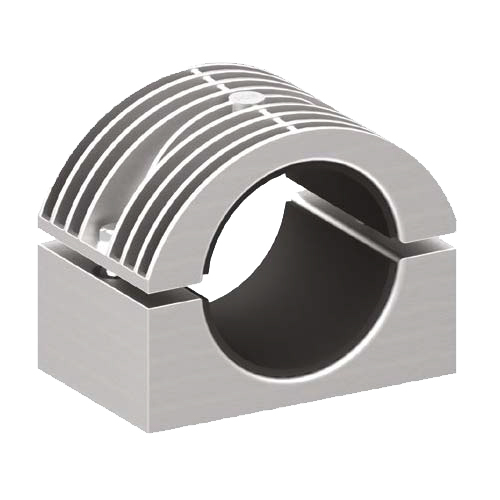

Prysmian BICON Single Way Heavy Duty Two Bolt Cleat 370HD Series (Aluminium)

Product overview

Prysmian BICON Single Way Heavy Duty Two Bolt Cleat 370HD Series (Aluminium) is made from aluminium specifically designed for HV cables installed along both horizontal and vertical routes.

Part Numbers: 370HD01, 370HD02, 370HD03, 370HD04, 370HD05, 370HD06

Single Way Heavy Duty Two Bolt Cleat – Features & Benefits

- Ideally suited for larger cables with diameters 100 to 159 mm.

- Manufactured from aluminium alloy.

- Two-piece, two fixing design.

- Operating temperature -60ºC to +105ºC.

- Designed to protect the cable sheaths during installation.

- Plain finish – for normal industrial areas or outdoor unpolluted areas.

- Epoxy coated versions available for harsher environments.

- Supplied with rubber liners.

- Prysmian BICON Single Way Heavy Duty Cleat (370HD) is tested in accordance with BS EN 61914.

- Spring loaded version available upon request.

For Additional Information on Prysmian BICON Single Way Heavy Duty Two Bolt Cleat 370HD Series (370HD01, 370HD03, 370HD05), please advise Technical Data Table or PDF Files below.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Interested in this Product?

+44 (0)1744 762 929Technical Data

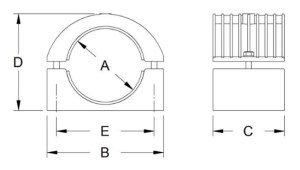

| Design Number - Standard | Design Number - Epoxy Coated | Cable Diameter A (mm) Min | Cable Diameter A (mm) Max | Dimensions B | Dimensions C | Dimensions D Max | Dimensions E | Weight (g) |

| 370HD01 | 370HE01 | 105 | 115 | 210 | 110 | 165 | 170 | 2517 |

| 370HD02 | 370HE02 | 115 | 125 | 220 | 220 | 175 | 180 | 2797 |

| 370HD03 | 370HE03 | 125 | 135 | 230 | 130 | 185 | 190 | 3268 |

| 370HD04 | 370HE04 | 135 | 145 | 240 | 140 | 195 | 200 | 3598 |

| 370HD05 | 370HE05 | 145 | 155 | 245 | 150 | 205 | 205 | 1853 |

| 370HD06 | 370HE06 | 155 | 165 | 260 | 160 | 215 | 220 | 4291 |

Performance Data

| Test Standard | BS EN 61914 |

| Type | 6.1.1 Non-Metallic |

| Impact Resistance | 6.3.3 V.Heavy |

| Lateral Load | 50 kN |

| Axial Load | 8 kN |

| Needle Flame | >120 secs |

Method Of Fixing

The single way cleat is opened up and placed around the cable so that the end of the cleat containing the slot will be in contact with the mounting surface, except for the 385LSF01, which should be reversed to put the slot uppermost. In this case an M5 washer should be used to prevent the nut entering the slot of the cleat.

*Technical information subject to change without notice