Crimping Standards: The Key to Safe & Reliable Connections

When it comes to creating reliable connections between electrical conductors, Crimping is a common method in various industries. However, not all crimping results are even or equal, and using the wrong standards can lead to subpar performance or even safety hazards. In this quick introduction guide, we’ll explore the different Crimping Standards you need to know and adhere to, to ensure the best possible results. We’ll also answer Frequently Asked Questions, like “What are Crimping Standards?”, “Why are they important?”, “Which types are there?” and “How to Follow Them“.

In addition to ensuring safe connections, it’s important to recognise that Crimping Standards also support compliance with legal and safety regulations. Using certified components and following installation standards like BS7609 and BS7727 not only promotes quality but helps meet UK electrical safety requirements.

What is Crimping and Why is it Important?

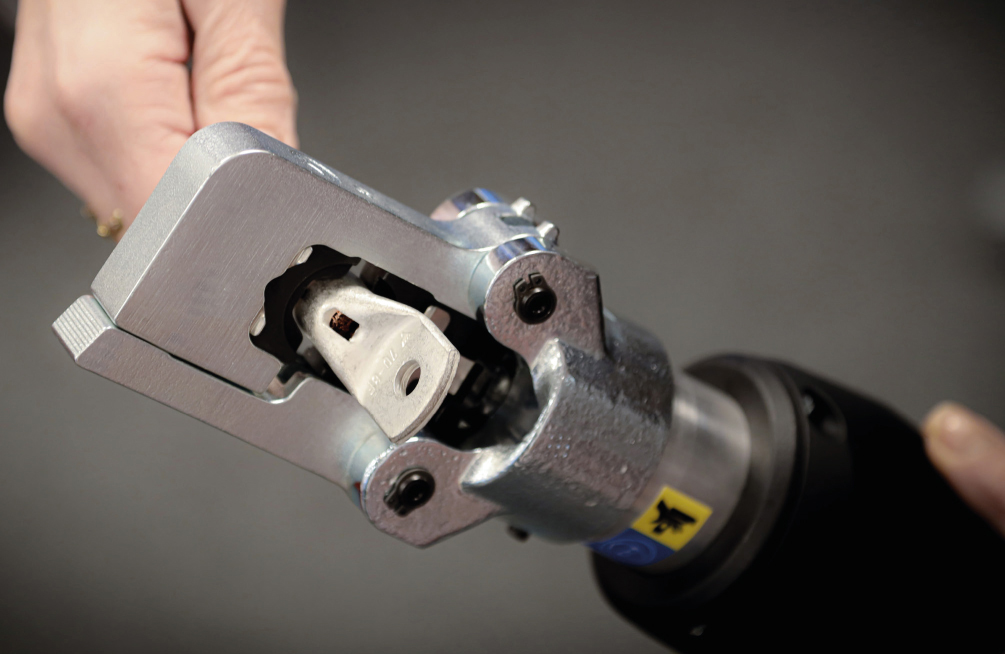

Crimping is a process of connecting and terminating wires or cables with cable lugs, connectors or terminals, using a specialised tool. This creates a secure and reliable electrical connection that can withstand mechanical stress and environmental factors.

Crimping is a process of connecting and terminating wires or cables with cable lugs, connectors or terminals, using a specialised tool. This creates a secure and reliable electrical connection that can withstand mechanical stress and environmental factors.

It is essential for ensuring the safety and efficiency of electrical systems. Poorly crimped connections can lead to high resistance, which can cause overheating and even electrical fires. Following investigations on the infamous Grenfell Tower fire back in 2017, experts said it was a “faulty electrical connection that started the blaze” – see this BBC article for more info.

In other industries, inadequate crimping can lead to unreliable connections. This can result in signal loss, data corruption, equipment damage or other system failures.

What are Crimping Standards?

Crimping Standards are a set of guidelines that dictate the proper ways, techniques and tools for making crimped connections. They ensure that crimped connections are correct, consistent and meet specific performance criteria, regardless of the manufacturer or tool used.

Standards are developed by organisations such as BSI, IEC, UL, CSA, and SAE, among others, and are used by manufacturers, electricians and other professionals in the electrical industry. In the UK, all Crimp Terminals must be tested and conform to IEC61238. Crimpers/ installers must adhere to installation standards BS7609 and BS7727.

- BS7609: A critical UK code of practice focusing on the installation and inspection of compression and mechanical terminals on power cables. It provides detailed guidance on materials, tooling, workmanship and testing to ensure safe, long-lasting electrical connections. Adhering to BS7609 helps installers comply with UK regulations and prevents costly failures.

- BS7727: A British Standard outlining installation and inspection guidelines for pre-insulated terminals on copper conductors. It helps manufacturers and installers ensure safe, reliable and consistent connections, supporting industry best practices across manufacturing engineering, and telecommunications.

Why are Crimping Standards Important?

Crimping Standards are important to follow for several reasons. Firstly, they ensure that crimped connections are safe and reliable, which is critical for preventing electrical failures and hazards. Secondly, they provide a consistent method for making crimped connections, which improves efficiency and reduces the risk of errors. Additionally, Crimping Standards provide a basis for testing and evaluating crimped connections, which helps ensure that they meet specific performance criteria. That way, the installer can achieve crimping consistency and quality criteria, regardless of the manufacturer of the tool system they use. Finally, using the right Crimping Standards can help to improve the longevity of electrical systems, which can save time and money in the long run.

Types of Crimping Standards

There are several types of Crimping Standards that are commonly used, including:

There are several types of Crimping Standards that are commonly used, including:

- IEC Standards: The International Electrotechnical Commission (IEC) is a global organisation that sets guidelines for crimped connectors. IEC standards cover a range of factors, including the conductor material, the crimp tool and the testing procedures. IEC61238 applies to the electrical and mechanical properties of cable lugs. It details the requirements for a permanent and safe electrical connection for the intended application.

- BS Standards: The British Standards Institution is the UK’s national standards body for producing technical standards on a wide range of products. BS7609 & BS7727 are the codes of practice focusing on the installation and inspection of un-insulated and pre-insulated compression and mechanical terminals and connectors for power cables with Copper or Aluminium conductors. (Full article here: BS7609 & BS7727: British Standards for Crimping)

- UL Standards: Underwriters Laboratories (UL) is a safety consulting and certification company, setting standards for crimping connectors, terminals and splices. UL standards cover a wide range of factors, including the material used, the crimping tool and the testing procedures.

- MIL-SPEC Standards: The military specification (MIL-SPEC) sets the standard for crimping in the military and aerospace industries. MIL-SPEC standards are very strict and require extensive testing to ensure that connections meet the necessary requirements.

- DIN Standards: Deutsches Institut für Normung (DIN) is a German standards organisation that sets guidelines for crimping connectors. DIN standards cover a range of factors, including the conductor material, the crimping tool and the testing procedures. DIN 46235 is a standard that defines the applications, dimensions and the designation of compression cable lugs. DIN 48083 includes codes of practice and dimensions for dies when used in pressure connections for hydraulic / mechanical presses.

- SAE Standards: The Society of Automotive Engineers (SAE) sets standards for crimping in the automotive industry. SAE standards cover a wide range of factors, including the conductor material, the crimping tool and the testing procedures.

Please note, flexible and compacted conductors require special tooling and techniques during crimping to avoid strand damage or poor compression. Industry Crimping Standards provide guidelines to ensure these conductor types maintain electrical and mechanical integrity throughout their service life.

How to Follow Crimping Standards

To follow Crimping Standards, it’s important to use the right crimping components and techniques for the specific application. Even if it’s not always mentioned, it is essential to make sure all components used in Crimping (terminal, wire gauge, crimping die and crimping tool) are part of a system and come from the same manufacturer. Or at least that their testing took place together as a system. For more on this subject please read our article: A Crimping System is No Stronger than its Weakest Link.

To follow Crimping Standards, it’s important to use the right crimping components and techniques for the specific application. Even if it’s not always mentioned, it is essential to make sure all components used in Crimping (terminal, wire gauge, crimping die and crimping tool) are part of a system and come from the same manufacturer. Or at least that their testing took place together as a system. For more on this subject please read our article: A Crimping System is No Stronger than its Weakest Link.

Using a matched and certified crimping system — comprising terminals, wires, dies and tools — is key to ensuring reliable, consistent crimps. Mixing components from different manufacturers or untested combinations can compromise connection quality and void certifications.

Properly stripping and preparing the wire before crimping is also essential. This should be followed by a careful visual inspection to identify any defects in the connection. Alongside adhering to these steps, using quality materials — such as wires, tools, dies and connectors or terminals — is crucial to ensure a safe and reliable crimped connection. Finally, thorough testing methods, including pull testing, electrical testing and visual checks, are necessary to verify the integrity and performance of the crimp.

Last but not least, regular calibration and maintenance of crimping tools is vital for consistent connection quality. Many standards require documented calibration records as part of quality assurance. Without it, tool performance may degrade, increasing the risk of faulty crimps and safety issues.

Good Crimping Practice Campaign

In conclusion, crimping standards are essential for ensuring safe, reliable and high-performing crimped connections in the electrical industry. By using the correct crimping techniques and employing quality components designed to work together as a system, electricians, manufacturers and other professionals can ensure reliable connections. Thorough testing of crimped connections then confirms they meet performance standards and remain free from defects.

Sadly, this is not always the case. The lack of awareness and application of bad crimping techniques is unfortunately encountered a lot in the industry (See Article: Crimping: Common Mistakes & Good Practice). To tackle this and minimise any potential dangers due to crimping, E-Tech Components launched a “Good Crimping Practice” Campaign.

Sadly, this is not always the case. The lack of awareness and application of bad crimping techniques is unfortunately encountered a lot in the industry (See Article: Crimping: Common Mistakes & Good Practice). To tackle this and minimise any potential dangers due to crimping, E-Tech Components launched a “Good Crimping Practice” Campaign.

As part of this campaign, E-Tech Components proudly offers:

- Lunch and Learn Seminars covering different types of standards and good crimping practices

- Free Certified Training whenever you purchase one of our Elpress Crimping Tool Systems

- On-site Inspection and Assessment of your company’s current Crimping Systems and procedures

- Free Advice on how to ensure compliance to the standards

High-Quality Lugs + Proper Crimping = Success

At the end of the day, high-quality cable lugs complement good crimping practice. Inferior lugs can have poor material quality or dimensional inconsistencies, which may lead to corrosion, overheating or mechanical failures. Using standards-compliant, reputable lugs reduces these risks and improves overall connection reliability.

For even more on Crimping Best Practices, check out our pilot episode of #ASKETECH featuring Paul Forester, our Operations Director and Elpress Crimping System Specialist.

Paul shares his 20 years of industry experience, highlights common crimping mistakes and explains why proper training is crucial for safe, reliable connections. He also discusses the impact of real-world events like the Grenfell Tower fire. Watch the full interview to master the art of crimping and ensure your connections meet the highest standards.

Follow links for more Blog Posts on: Crimping, Tooling, Standards & Regulations.