Prysmian BICON 378AD Multicleat (Epoxy Coated Base)

Product overview

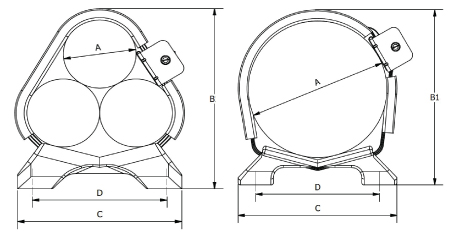

Prysmian BICON 378AD Multicleat/ Multistrap with Epoxy Coated Base is a Cable Cleat Series that can be used for both Single and Trefoil Cable Cleat Applications. A new and improved locking mechanism making the installation quicker and easier. Suitable for use with single cable diameters 36 to 120mm and trefoil cable diameters 24 to 145mm.

Part Numbers (Standard): 378AD01, 378AD02, 378AD03, 378AD04, 378AD05, 378AD06, 378AD07, 378AD08, 378AD09.

Part Numbers (Heavy Duty): 378AD51, 378AD52, 378AD53, 378AD54, 378AD55, 378AD56, 378AD57, 378AD58, 378AD59, 378AD36, 378AD37, 378AD38, 378AD39, 378AD40, 378AD41, 378AD42.

Prysmian BICON 378AD Features & Benefits

- Suitable for use with trefoil cable diameters 24 to 145mm.

- Suitable for use with single cable diameters 36 to 120mm.

- Large range take on each size.

- All straps manufactured from non-magnetic 316L Stainless Steel (377AB).

- Plain Aluminium bases available for normal industrial areas or outdoor unpolluted areas (378AB).

- Liners are made from LS0H materials.

- Suitable for single core cables laid in trefoil formation with high fault current capacities.

- Suitable for use with all standard ladder and tray systems.

- Suitable for groups of dissimilar cables.

- Tested in accordance with BS EN 61914 (IEC 61914).

Installation Sequence

Prysmian BICON 378AD Multicleats (e.g. 378AD01) come with a disposable tensioning aid (introduced in response to customer requests to improve speed and tightness of installation). The adapter fits into the open end of the winding pin and used with a standard 13mm socket wrench to tighten the strap. Installer can then use the same 13mm socket to tighten the locking nut and finish the installation.

| STEP 1

Fasten base to support with M10 fixings. Loop strap through base and around cables (2 loops for Standard, 3 loops for Heavy Duty). |

| STEP 2

Pull slack into the outer loop. Insert a split pin around the outer strap layer 10mm from the end. Attach the plastic shear torque adapter and a 13mm socket wrench. Rotate the key counterclockwise with the wrench to tension the strap until the adapter shears. |

| STEP 3

Remove the shear torque adapter and wrench. Swing the key over and engage in slots in clip. |

Performance Data – BS EN 61914

Type: Composite

Operating Temperature: -40°C to +120°C

Corrosion Resistance: High, Outdoor – Wet unpolluted conditions

Ultraviolet Light Resistance: Pass

Electromechanical Forces Resistance (= 1 short circuit):

– Standard duty strap (2 wraps): 57.3kA RMS, 126kA Peak, cleat spacing = 600mm, cable Ø = 38mm

Electromechanical Forces Resistance (> 1 short circuit):

– Standard duty strap (2 wraps): 52.3kA RMS, 115kA Peak, cleat spacing =600mm, cable Ø = 38mm

– Heavy duty strap (3 wraps): 55kA RMS, 121kA Peak, cleat spacing = 600mm, cable Ø = 38mm

For Additional Information on Prysmian BICON 378AD Multicleat (e.g. 378AD01), please advise Technical Data Table or PDF Files below.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Used in

London Underground

Interested in this Product?

+44 (0)1744 762 929Technical Data

| Epoxy Coated - Standard |

Epoxy Coated - Heavy Duty |

Trefoil Cable ∅ - Min |

Trefoil Cable ∅ - Max |

Trefoil Height (B) |

Single Cable ∅ - Min |

Single Cable ∅ - Max |

Single Height (B1) |

C | D | Weight | Multistrap - Standard |

Multistrap - Heavy Duty |

| 378AD01 | 378AD51 | 24 mm | 34 mm | 95 mm | 36 mm | 65 mm | 92 mm | 126 mm | 100 mm | 0.540 kg | 377AB01 | 377AB51 |

| 378AD02 | 378AD52 | 30 mm | 41 mm | 110 mm | 60 mm | 85 mm | 113 mm | 126 mm | 100 mm | 0.570 kg | 377AB02 | 377AB52 |

| 378AD03 | 378AD53 | 37 mm | 47 mm | 121 mm | 80 mm | 90 mm | 118 mm | 122 mm | 96 mm | 0.576 kg | 377AB03 | 377AB53 |

| 378AD04 | 378AD54 | 43 mm | 54 mm | 135 mm | 85 mm | 110 mm | 138 mm | 122 mm | 96 mm | 0.595 kg | 377AB04 | 377AB54 |

| 378AD05 | 378AD55 | 50 mm | 60 mm | 146 mm | - | - | - | 132 mm | 106 mm | 0.636 kg | 377AB05 | 377AB55 |

| 378AD06 | 378AD56 | 56 mm | 67 mm | 160 mm | - | - | - | 132 mm | 106 mm | 0.657 kg | 377AB06 | 377AB56 |

| 378AD07 | 378AD57 | 63 mm | 73 mm | 172 mm | - | - | - | 176 mm | 150 mm | 0.798 kg | 377AB07 | 377AB57 |

| 378AD08 | 378AD58 | 69 mm | 80 mm | 186 mm | - | - | - | 176 mm | 150 mm | 0.818 kg | 377AB08 | 377AB58 |

| 378AD09 | 378AD59 | - | - | - | 105 mm | 120 mm | 148 mm | 122 mm | 96 mm | 0.614 kg | 377AB09 | 377AB59 |

| - | 378AD36 | 72 mm | 85 mm | 190 mm | - | - | - | 230 mm | 200 mm | 0.832 kg | - | 377AB36 |

| - | 378AD37 | 82 mm | 95 mm | 210 mm | - | - | - | 230 mm | 200 mm | 0.864 kg | - | 377AB37 |

| - | 378AD38 | 92 mm | 105 mm | 230 mm | - | - | - | 284 mm | 242 mm | 1.449 kg | - | 377AB38 |

| - | 378AD39 | 102 mm | 115 mm | 250 mm | - | - | - | 284 mm | 242 mm | 1.480 kg | - | 377AB39 |

| - | 378AD40 | 112 mm | 125 mm | 270 mm | - | - | - | 284 mm | 242 mm | 1.511 kg | - | 377AB40 |

| - | 378AD41 | 122 mm | 135 mm | 290 mm | - | - | - | 284 mm | 242 mm | 1.542 kg | - | 377AB41 |

| - | 378AD42 | 132 mm | 145 mm | 315 mm | - | - | - | 290 mm | 242 mm | 1.572 kg | - | 377AB42 |

|