Prysmian BICON Single Way Altus Cable Cleat 370FA Series

Product overview

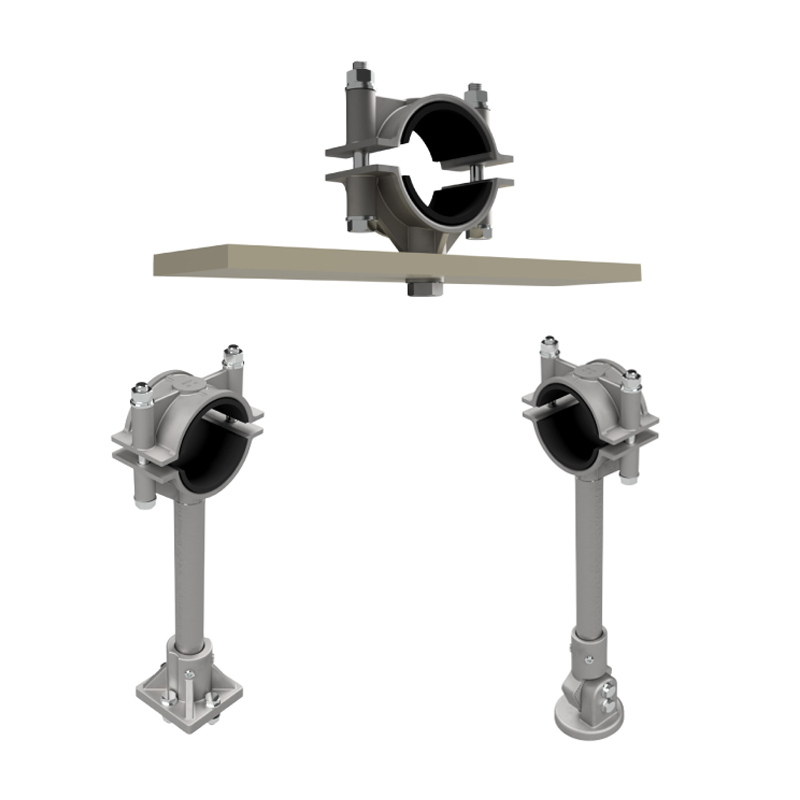

Prysmian BICON Altus Cable Cleat 370FA Series offers a versatile and reliable solution for cable management applications, manufactured from aluminium alloy. Their design, development, testing and manufacturing are in accordance with BS EN 61914:2016 & IEC 61914:2015 (cable cleats for electrical installations). That ensures retention and support of cables, without sustaining damage to them. They can attach directly to a cable ladder while also offering the option of using with fixed (3702102) or swivel bases (3702105) – ordered separately.

Part Numbers: 370FA10, 370FA11, 370FA12, 370FA13, 370FA14, 370FA15, 370FA16, 370FA17, 370FA18, 370FA19.

Altus Cable Cleat – Features & Benefits

- Suitable for use with cable diameters 50 to 152mm.

- Manufactured from aluminium alloy.

- Two-piece cleat design.

- With a single M16 thread, the cleat can attach directly to cable ladder, tray or structure.

- Can be used in an extended assembly.

- Can be used with optional fixed or swivel bases.

- Suitable for Low, Medium and High Voltage cables.

- Suitable for all types of cable routes.

- Cleat supplied with 5mm rubber liner as standard.

- Tested in accordance with IEC 61914:2015.

For Additional Information, Performance Data and Cleat Selection Table on Prysmian BICON Altus Cable Cleat 370FA Series (e.g. 370FA10, 370FA11, 370FA12, etc.), please advice PDF File or Technical Data Tables below.

*Technical Data subject to change without notice.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Interested in this Product?

+44 (0)1744 762 929Technical Data

| Design Number | Cable Diameter Min Ø (mm) | Cable Diameter Max Ø (mm) | A (mm) | B (mm) | C (mm) | D (mm) | Weight (g) |

| 381QC01 | 20 | 24 | 54 | 85 | 55 | centre hole only | 208 |

| 381QC02 | 23 | 28 | 62 | 93 | 55 | centre hole only | 228 |

| 381QC03 | 27 | 32 | 70 | 101 | 55 | centre hole only | 249 |

| 381QC04 | 31 | 36 | 78 | 109 | 55 | centre hole only | 269 |

| 381QC05 | 35 | 41 | 88 | 119 | 55 | 25 | 286 |

| 381QC06 | 40 | 46 | 98 | 129 | 55 | 25 | 311 |

| 381QC07 | 45 | 51 | 108 | 139 | 55 | 25 | 337 |

| 381QC08 | 50 | 58 | 122 | 153 | 55 | 50 | 367 |

| 381QC09 | 57 | 65 | 136 | 167 | 55 | 50 | 403 |

| 381QC10 | 64 | 70 | 146 | 177 | 55 | 50 | 433 |

| Note: All cleats have a single central fixing hole for a 10mm diameter fixing bolt. Styles 05 to 10 can also be fixed with 2 x 10mm bolts - the 10mm clearance holes are positioned either side of the central hole with centres as per dimension D. |

Additional Information

| BS EN 61914:2021 (IEC 61914:2020) | Clause | Classification |

| Type | 6.1.3 | Composite |

| Operating Temperature | 6.2 | -60°C to +105°C |

| Impact Resistance | 6.3.4 | Heavy |

| Lateral Load | 6.4.2 | Orientation 2a: 12.6 kN – 15.8 kN | Orientation 2c: 7.2 kN – 8.2 kN |

| BS EN 61914:2016 (IEC 61914:2015) | Clause | Classification |

| Axial Load | 6.4.3 | 1 kN – 3.5 kN |

| Resistant to more than one short circuit | 6.4.5 | 42.4 kA RMS, 100 kA Peak, Ø = 74.4 mm, spacing = 2000 mm |

| UV Resistance | 6.5.1 | Resistant to ultraviolet light |

| Corrosion Resistance | 6.5.2 | High, Outdoor – wet conditions |