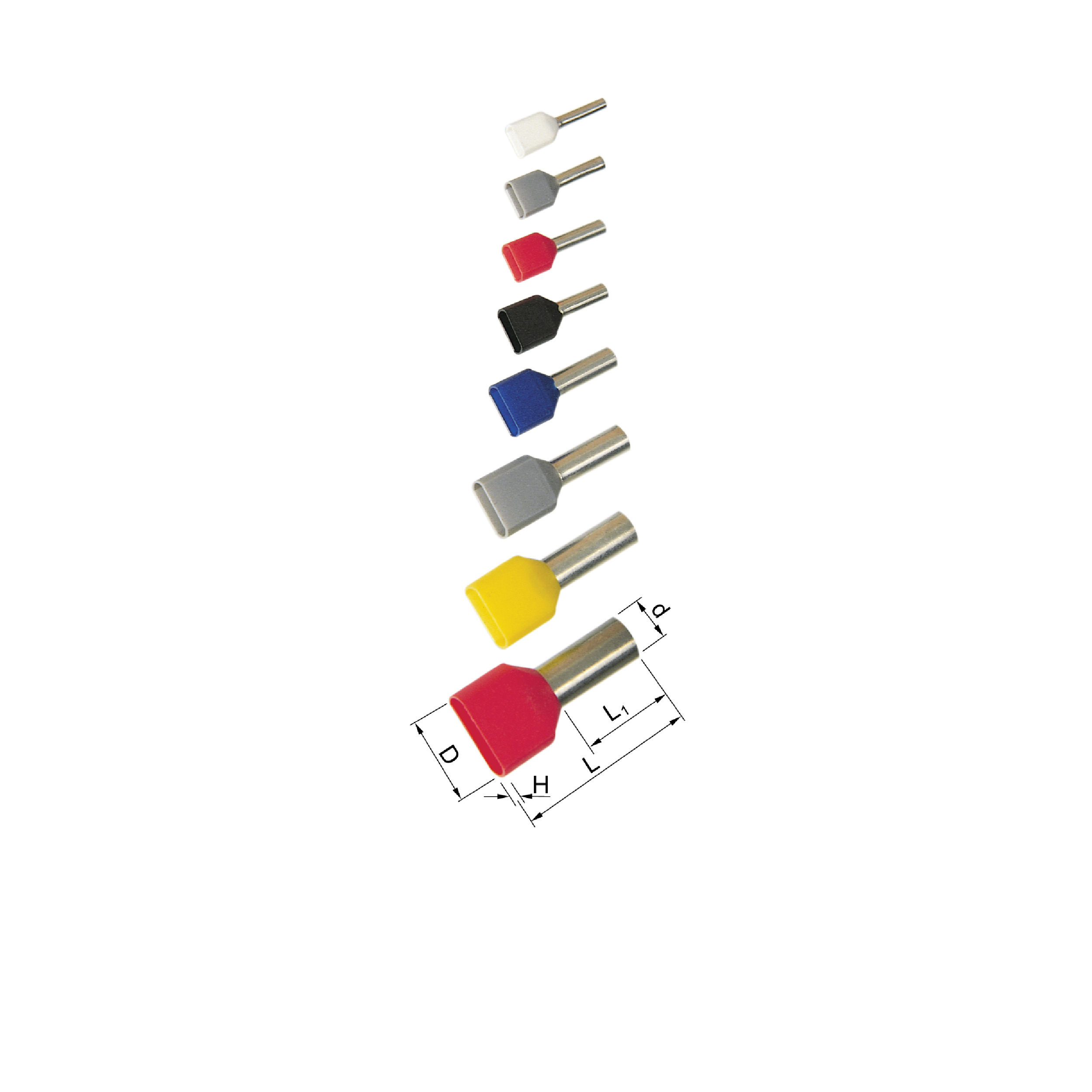

Elpress ET2 Pre-Insulated Twin End Terminals – Standard colour (2×0.5-2x10mm²)

Product overview

Elpress ET2 Pre-Insulated Twin End Terminals

Elpress ET2 Pre-Insulated Twin End Terminals – Standard colour (2×0.5-2x10mm²) manufactured of electrolytic copper, tin plated and designed to connect two conductors in one terminal (Range 2×0.5-2x10mm², Type ET2, Standard Colour).

Part Numbers: A0,5-6ET2, A0,5-8ET2, A0,75-8ET2, A0,75-10ET2, A0,75-12ET2, A1-8ET2, A1-10ET2, A1-12ET2, A1,5-8ET2, A1,5-12ET2, A2,5-10ET2, A2,5-13ET2, A4-12ET2, A4-18ET2, A6-14ET2, A6-18ET2, A10-14ET2.

General Information

SYSTEM ELPRESS

System Elpress consists of Terminals and Tools designed and tested together to give a certified crimping result. This ensures that users will feel confident when using our systems, and the achievement of a secure connection through the proper handling of our products. By using Elpress Cu-Connection elements together with one of Elpress Crimp Systems one obtains a connection tested according to the requirements of IEC 61238:1.

PRE-INSULATED TERMINALS

Elpress ring, fork and pin terminals made of high-class copper 99.95%. The tab and bullet terminals made of brass or tin-bronze. All terminals are then electrolytically tin-plated for maximum corrosion protection. The terminal’s neck is brazed and annealed, which means it can be crimped in any direction. The metal in the receptacles’ neck double folded. This means that the finished terminal has excellent mechanical strength and low resistance.

Marking

LABELLING OF PRE-INSULATED TERMINALS

Elpress system for marking Al and AlCu Terminals shows the conductor area and reference to rounded and contact crimping tools, within the Elpress range. A tool reference for hexagonal crimping copper is give on the bimetallic through connectors.

For more information on Elpress ET2 Pre-Insulated Twin End Terminals (A1-8ET2, A4-12ET2, A6-14ET2), see Technical Data below.

*Technical Data subject to change without notice.

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us for enquiries concerning this and all other products: +44 (0) 1744 762 929

Interested in this Product?

+44 (0)1744 762 929Technical Data

- Material: Cu 99.95%, tin plated Cu/Sn, CSA Approved.

- Polypropylene insulation, colour code according to DIN 46228.

| Insulation Colour | AWG | mm² | Cat. No. | d mm | H/ D | L1 | L | s | Pcs/ Pack | Rec. Tool* |

| 2 x 20 | 2 x 0,5 | A0,5-6ET2 | 1.5 | 2.3/4.5 | 6 | 13 | 8 | 100 | PEB0110T | |

| 2 x 20 | 2 x 0,5 | A0,5-8ET2 | 1.5 | 2.3/4.5 | 8 | 15 | 10 | 100 | PEB0110T | |

| 2 x 20 | 2 x 0,75 | A0,75-8ET2 | 1.8 | 2.6/5.1 | 8 | 15 | 10 | 100 | PEB0110T | |

| 2 x 20 | 2 x 0,75 | A0,75-10ET2 | 1.8 | 2.6/5.1 | 10 | 17 | 12 | 100 | PEB0110T | |

| 2 x 20 | 2 x 0,75 | A0,75-12ET2 | 1.8 | 2.6/5.1 | 12 | 19 | 14 | 100 | PEB0110T | |

| 2 x 18 | 2 x 1 | A1-8ET2 | 2 | 3.0/5.1 | 8 | 15 | 10 | 100 | PEB0110T | |

| 2 x 18 | 2 x 1 | A1-10ET2 | 2 | 3.0/5.1 | 10 | 17 | 12 | 100 | PEB0110T | |

| 2 x 18 | 2 x 1 | A1-12ET2 | 2 | 3.0/5.1 | 12 | 19 | 14 | 100 | PEB0110T | |

| 2 x 16 | 2 x 1,5 | A1,5-8ET2 | 2.3 | 3.5/6.4 | 8 | 16 | 10 | 100 | PEB0110T | |

| 2 x 16 | 2 x 1,5 | A1,5-12ET2 | 2.3 | 3.5/6.4 | 12 | 20 | 14 | 100 | PEB0110T | |

| 2 x 14 | 2 x 2,5 | A2,5-10ET2 | 2.9 | 4.0/7.5 | 10 | 18.5 | 12 | 100 | PEB0110T | |

| 2 x 14 | 2 x 2,5 | A2,5-13ET2 | 2.9 | 4.0/7.5 | 13 | 21.5 | 15 | 100 | PEB0110T | |

| 2 x 12 | 2 x 4 | A4-12ET2 | 3.8 | 4.9/8.6 | 12 | 23 | 14 | 100 | GEB4010C-TWIN, PEB0110T | |

| 2 x 12 | 2 x 4 | A4-18ET2 | 3.8 | 4.9/8.6 | 18 | 29 | 20 | 100 | GEB4010C-TWIN, PEB0110T18 | |

| 2 x 10 | 2 x 6 | A6-14ET2 | 4.6 | 5.8/9.6 | 14 | 25 | 16 | 100 | GEB4010C-TWIN, PEB0110T18 | |

| 2 x 10 | 2 x 6 | A6-18ET2 | 4.6 | 5.8/9.6 | 18 | 29 | 20 | 100 | GEB4010C-TWIN, PEB0110T18 | |

| 2 x 8 | 2 x 10 | A10-14ET2 | 6.5 | 7.0/12.6 | 14 | 26 | 16 | 100 | GEB4010C-TWIN |

s= strip length

*Use the tool socket closest to the total area of the sleeve.