The Definitive Guide to Cable Troughing

Table of Contents

- Introduction

- What is Cable Troughing?

- Why Use Cable Troughs?

- Plastic Cable Troughs vs. Concrete: Why Plastic is the Preferred Choice

- Installation Method

- Laws & Regulations

- E-Tech Components: Your Source for TTS Cable Troughing

- E-Tech Components: Our TTS Green Trough Range

- Frequently Asked Questions

- Additional Resources for Further Reading

- FREE Technical Advisory Service

Introduction

If you’ve ever wondered “what is cable troughing?” or “are plastic troughs a better option than concrete?”, stick around! This blog will tell you everything there is to know about the safe and reliable routing of cables. From bustling industrial complexes and hyperscale data centres to cross-country rail systems, the ever-so-dependable cable trough plays a crucial role in contemporary cable route management.

This comprehensive guide delves into the world of cable troughing, providing electricians and professionals with in-depth knowledge about its purpose, benefits, installation and industry best practices. In this blog, we’ll explore the various types of cable troughs we stock and distribute at E-Tech. We’ll also discuss relevant industry standards, regulations and the advantages of using high-quality lightweight solutions like Green Trough by Trough-Tec Systems and Furukawa Electric. By the end of this guide, you will have a solid understanding of cable troughing and be equipped to select and install the most suitable cable trough system for your specific project.

What is Cable Troughing?

Cable Troughing (often called Cable Raceway, Cable Routing System, Cable Management Trough, Electrical or Industrial Cable Routing) is a specialised system designed to protect, organise and route electrical cables within a defined pathway. Essentially, it provides a secure and accessible channel for cables, wires and ducts, preventing damage and ensuring efficient cable route management.

Materials

Cable troughs are typically made from durable materials. The most common are:

Glass Reinforced Plastic (GRP Cable Troughs): Lightweight, strong and corrosion-resistant, these cable troughs are easy to handle and install. They’re ideal for harsh environments due to their chemical and UV resistance, and they’re also fire and non-conductive for safety. With low maintenance needs, a long lifespan and recyclability, GRP cable troughs are cost-effective and environmentally friendly cable routing solutions.

Glassfibre Reinforced Concrete (GRC Cable Troughs): Significantly lighter than traditional concrete options, this makes transportation and installation much easier and quicker. Strong and resistant to breakage, they can be easily worked with using standard hand tools. Resistant to rust and rot, they also boast excellent fire resistance, making them suitable for demanding environments.

Concrete Cable Troughs: Renowned for their durability, fire resistance, and load-bearing capacity, concrete cable troughs are a robust and secure choice for cable protection. However, we believe PVC / plastic cable troughs have several advantages over their concrete counterparts. Carry on reading this blog to learn about the limitations of concrete.

PVC Cable Troughs / Plastic Cable Troughs: PVC or plastic cable troughs are lightweight, corrosion-resistant and cost-effective, making them easy to install and maintain. Their versatility in size and shape allows for adaptability to various cable layouts. We’ll explain more later on.

Applications

Coming in various sizes and configurations to accommodate different cable capacities and installation requirements, they are widely used in a range of different environments, including:

- Rail / Traction

- Construction Projects

- Data Centres

- Renewable Energy

- Utilities & Telecommunications

- Power Plants

- Stadiums

- Airports

- Highways

- And more

Key components of a cable troughing system include:

- Base: Provides a stable foundation

- Cover: Protects cables from physical damage and environmental factors

- Dividers: Optional components used to separate different cable groups within the trough

- Bends, Gradients & Elevated Systems: Suitable for avoiding obstacles, taking the route around or over them.

- Accessories: Additional components such as junctions, reducers / adaptors and end caps for complete system assembly

Carry on reading to understand the fundamental principles of cable routing systems. From here, you can select the most appropriate cable route management system for your specific project.

Why Use Cable Troughs?

Organisation and Accessibility

Providing a defined pathway for cables, cable raceways prevent them from being carelessly routed. The end result is a professional and visually appealing installation. Improving the overall aesthetics of a project, cable raceways ultimately make it easier to identify and trace cables.

Because cables are contained within the trough, this makes them readily visible and accessible for inspection, maintenance or modifications. In turn, this reduces downtime because technicians can quickly locate and address any issues without disrupting other components.

Protection

In addition to enhancing aesthetics, cable troughing serves as a protective barrier, shielding cables from damage due to impacts, crushing, abrasion or adverse environmental conditions. This protection is especially crucial in environments with heavy machinery or significant foot traffic. For example, railway cable troughs are essential where linemen or rail professionals frequently access the tracks, often at night, for maintenance and repairs.

Additionally, the enclosed structure of a cable trough system shields cables from moisture, dust and other non-environmental contaminants that can degrade their performance and lifespan. This is crucial in harsh or corrosive environments.

Safety

By containing cables in a non-combustible cable trough, the risk of fire spreading is minimised. In the event of a short circuit or overheating, the trough can help to prevent the fire from reaching other combustible materials.

Moreover, cable management raceways help prevent accidental contact with exposed live wires. This reduces the risk of electric shocks for both workers and the public.

Flexibility and Efficiency

Cable routing systems are modular and customisable, enabling quick and easy installation to meet bespoke project requirements. This design reduces labour costs and project timelines while providing flexibility during both the design and installation processes. Essentially, project managers can add or remove sections as needed.

Sure, there is an initial investment in cable raceways. However, it can lead to long-term cost savings by preventing damage to cables, reducing downtime and improving safety. This can result in lower maintenance costs and increased productivity.

Plastic Cable Troughs vs. Concrete: Why Plastic is the Preferred Choice

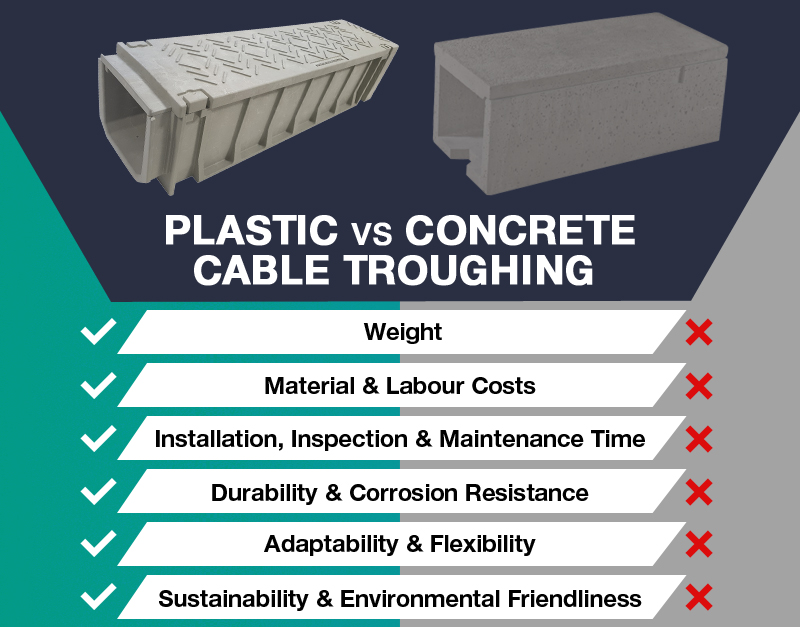

Plastic cable troughs / PVC cable troughs offer a multitude of advantages over concrete cable troughs. Why? Because their significantly reduced weight makes them exceptionally easy to handle, transport and install, often requiring less personnel and equipment. Ultimately, installations can be expedited with reduced labour costs too.

Plastic cable troughs / PVC cable troughs offer a multitude of advantages over concrete cable troughs. Why? Because their significantly reduced weight makes them exceptionally easy to handle, transport and install, often requiring less personnel and equipment. Ultimately, installations can be expedited with reduced labour costs too.

Compared to their concrete counterparts, plastic cable troughs are highly adaptable, allowing for easy modifications in cable routing or quantities, and providing flexibility throughout a particular project’s lifecy

cle. Their corrosion resistance and low maintenance ensure long-term durability and performance in various environmental conditions.

Using PVC cable troughs is an excellent way to ensure compliance while providing easy access for inspection, repairs and maintenance. These troughs are approved by major railway authorities, including Network Rail, New South Wales, Banedanmark, and Japan Railways.

From a financial perspective, PVC or plastic cable troughs are generally more cost-effective than concrete, both in terms of material and installation expen

ses. Additionally, the recyclability of plastic makes it a more environmentally friendly option compared to concrete. In the age of sustainable construction practices, it’s no wonder that solutions like Green Trough are gaining popularity. Stay tuned, as we will discuss this product from Trough-Tec Systems and Furukawa Electric in more detail later in the blog.

Installation Method

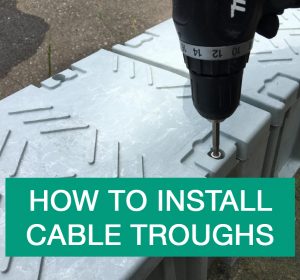

How to install Cable Troughs

Installing cable troughing might seem complex, but with the right approach, it can be a straightforward process. Here’s a basic overview:

- Determine the cable routing path and required trough size; ensure the installation area is clear of obstructions; and gather the necessary tools and equipment.

- Securely fix the base of the cable trough to the desired surface using appropriate fasteners; and ensure the base is level for proper alignment and stability.

- Carefully route cables through the trough and ensure they are organised and securely placed with the use of cable ties, bundles other methods.

- Align the cover with the base and secure it using the provided fasteners; and ensure a tight fit to protect the cables from external elements.

- If required, install bends, junctions or other accessories to accommodate cable routing changes.

- Verify that all cables are properly routed and secured within the trough; and check for any gaps or damage to the trough and its components.

Every manufacturer, however, has some additional steps or differentiators in this process according to their solutions’ requirements. To download the Trough-Tec Systems and Furukawa Electric Green Trough Installation Manual, please follow the link below:

Laws & Regulations

What does the law say about cable troughing?

Adhering to relevant laws and regulations is crucial for ensuring the safety and compliance of your electrical installation. Cable troughing, as a critical component of cable route management, is subject to specific standards and guidelines.

Key Regulations and Standards to consider

BS EN 50086 provides requirements for cable trays and trunking systems, including cable troughing, covering design, materials, testing and installation aspects. Local building regulations may outline specific requirements to ensure fire safety and structural integrity too. Additionally, adherence to electrical safety regulations, such as those issued by the relevant national authority (e.g., IET Wiring Regulations in the UK), is essential for preventing electrical hazards.

Other important considerations

Cable troughs must be selected and installed to meet fire resistance requirements, preventing the spread of flames and smoke. They must also be capable of supporting the weight of the installed cables and any additional loads, such as personnel or equipment. Additionally, cable troughs should be resistant to the environmental conditions of the installation area. This includes humidity, temperature extremes and corrosive substances. Furthermore, cables within the trough must be easily accessible for inspection, maintenance and modification.

By understanding and complying with these regulations, you can ensure that your cable routing system meets the highest safety and performance standa

rds.

E-Tech Components: Your Source for TTS Cable Troughing

E-Tech Components is proud to stock and distribute Green Trough by Trough-Tec Systems and Furukawa Electric. This is the world’s most versatile system of its kind, available in 6 cable trough sizes and ideal for a wide range of installations and cable types.

An innovative, environmentally friendly and state-of-the-art solution, Green Trough is a genuine concrete replacement – perfect for reducing installation time and associated costs.

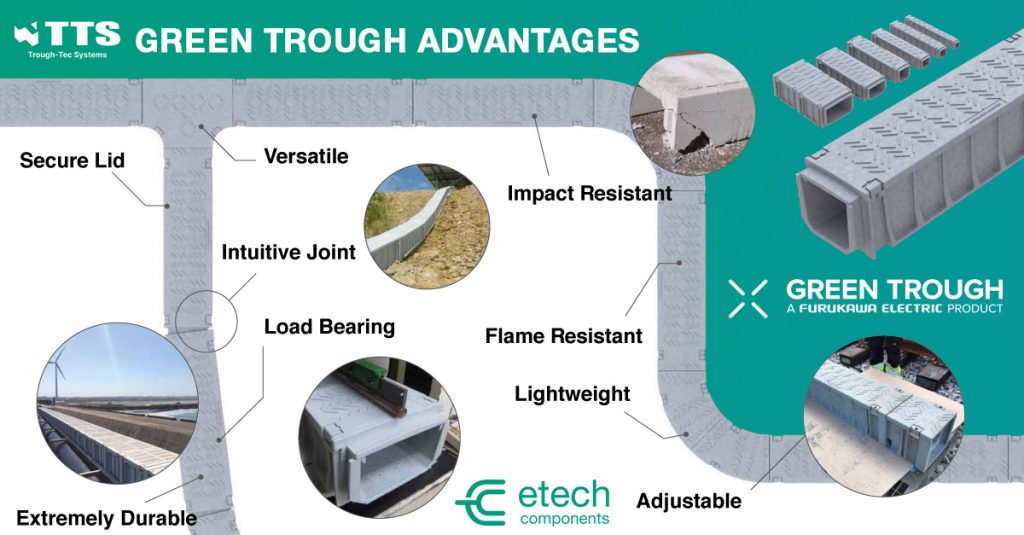

Key Benefits of TTS Green Trough:

- Secure Lid: Prevents accidental contact with live cables and protects against debris and moisture. TTS Green Trough offers a variety of lid fixings to suit specific security and access requirements.

- Versatile: Accommodates various cable sizes and configurations with a wide range of straight, bend, gradient and T-junction options. This cable trough system boasts an extensive range of sizes and accessories, including an elevated system.

- Intuitive Joint: Facilitates easy installation and adjustments, allowing for seamless integration around obstacles. This cable raceway’s joint system enables up to 5 degrees of vertical and horizontal deviation without additional accessories.

- Load Bearing: Supports the weight of personnel and equipment, ensuring safety and durability. This cable routing system can withstand a vertical load of 10kN/m.

- Extremely Durable: Resists harsh environmental conditions and prolonged use. This cable management trough offers 50+ years of UV resistance, operates in temperatures from -40°C to 80°C and is resistant to salt, snow melting agents and acid rain.

Key Benefits of TTS Green Trough (Continued):

- Impact Resistant: Minimises damage from accidental drops or impacts during installation. TTS Green Trough sustains only superficial damage when dropped from 0.7m and will not crumble like concrete alternatives.

- Lightweight: Reduces physical strain on installers and transportation costs. This industrial cable routing is approximately 70% lighter than concrete alternatives, enabling one-person lifting for efficient installation.

- Flame Resistant: Meets stringent fire safety standards, ensuring the protection of personnel and property. This electrical cable routing is halogen-free and complies with IEC 61084-1 and DIN 53438 standards.

- Adjustable: Allows for on-site modifications without specialised equipment. TTS Green Trough units can be manually shortened and processed with basic hand tools, eliminating dust generation.

By incorporating cable raceways into your electrical installations, you can significantly improve safety, efficiency and maintainability. TTS Green Trough’s exceptional qualities further enhance these benefits, providing a sustainable and high-performance solution for your cable route management needs.

E-Tech Components: Our TTS Green Trough Range

| Description | |

|

Straight Series (Standard): |

|

Straight Series (With Dividers): |

|

Bend Series (45 Degrees): |

|

Gradient Series (Downward): |

|

Gradient Series (Upward): |

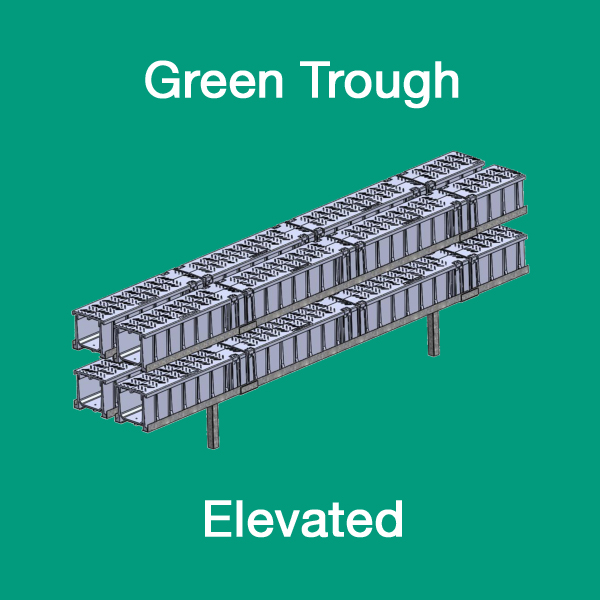

E-Tech Components: Our TTS Green Trough Range (Continued)

| Description | |

|

Elevated System: |

|

T-Junction Series: |

|

Anti-Slip Walkway System: |

|

TTS Green Trough Accessories: |

Since 2004, E-Tech Components has been connecting power in the electrical industry. Our expertise ensures we provide products that save time, reduce costs, improve quality and ensure compliance with standards and regulations.

As experts, stockists and distributors, we take pride in offering high-quality products and solutions at the best prices. What truly sets us apart is our tireless commitment to Customer Service and Technical Support. Our In-house Tool Repair & Calibration Centre further distinguishes us, making us unique in the electrical industry.

Frequently Asked Questions

Is There a Specific Weight Limit for Cable Troughs?

Yes, cable troughs have load-bearing capacities. It’s essential to choose a trough that can safely support the weight of the cables and any potential additional loads. For example, TTS Green Trough manufactures its Vehicle Rated lid using a galvanised zig-zag grating process that combines recycled polymer with advanced reinforcement. The end result is a strong, lightweight cover that is capable of carrying the weight of large vehicles.

Can I Use Cable Raceways Outdoors?

Yes, designers create most cable raceways for outdoor use, ensuring they can withstand various weather conditions. It’s important to select a raceway suitable for the specific outdoor environment.

Are Cable Troughs Fire-Resistant?

Many cable troughs are manufactured with fire-resistant materials to meet safety standards. For example, TTS Green Trough meets fire safety standards by being halogen-free and complying with IEC 61084-1 and DIN 53438 standards. Whatever product you choose, you should refer to its specifications for exact fire ratings.

How Do I Clean Cable Troughs?

Regular cleaning is essential for maintaining the performance of your cable trough system. Use mild cleaning agents and avoid abrasive materials that could damage the trough.

Additional Resources for Further Reading

- Trough-Tec Systems – TTS Rail

- Furukawa Electric Group

- The Definitive Guide to Underground Cable Ducting

FREE Technical Advisory Service

E-Tech Components UK Ltd maintains a free technical advisory service.

Contact us about any questions, enquiries or requests you may have: +44 (0) 1744 762 929

Written by: Taylor Williams.