The Definitive Guide to Underground Cable Ducting

Table of Contents

- INTRODUCTION

- WHAT IS UNDERGROUND CABLE DUCTING?

- USES / APPLICATIONS

- WHY USE IT? / IMPORTANCE

- DUCT INSTALLATION METHOD

- LAWS & REGULATIONS

- FURUKAWA ELECTRIC CABLE DUCTING & ACCESSORIES

- FREQUENTLY ASKED QUESTIONS

INTRODUCTION

Ever wondered, what is underground cable ducting? Perhaps you’re curious about where it’s used or why there are so many types and colours of electric ducting. Or maybe you’re not sure about how to install cable ducting? Or what the law says about it? All of these questions will be answered in this article, tailor-made just for you!

Ducting can be a confusing topic, since many people associate the term with ventilation over utilities. And it’s definitely troublesome to find every answer you need in just one place. While that was previously the case, it isn’t anymore, because we did it! We gathered all the information we could find and compiled this article, to answer every single FAQ on underground cable ducting.

WHAT IS UNDERGROUND CABLE DUCTING?

What is Cable Ducting?

Cable ducting is a cabling protection system. Essentially, it’s a passageway for electricity/power/other types of cables to run through. Designed as durable and impact-resistant as possible, this makes sure that cables are protected from weather and any other external factor.

What is Underground Cable Ducting?

In the UK, underground electric cable ducting must comply with ENATS (Energy Network Association Technical Specification) 12-24 classes. It must also be manufactured according to BS EN 61386 (which superseded BS EN 50086). The local electricity provider should be able to advise which ducting class is required for your project.

Material & Class Types

Electric cable ducting is typically classified into three types – Class 1 for high voltage, Class 2 for low voltage and Class 3 for general-purpose applications. Apart from the colour coding (advise Laws & Regulations paragraph below) and the class types, underground ducting also comes in a range of different materials and designs. Ultimately, different types of utilities and installations require different types of ducting.

Plastic ducting is the most common these days, but even this comes in different types. Polyethylene and UPVC are usually the materials of choice for solid wall pipes. Their design suits various applications depending on the specification and project requirements. You should use Twinwall HDPE pipes in areas that require extra strength, such as beneath heavy concrete under roads or pavement. However, all pipe materials come in different compression strengths and SN ratings. So it’s always best to have a look at the manufacturer’s technical datasheet before installing.

USES / APPLICATIONS

Cable ducting plays a crucial role in protecting all kinds of underground services — from electrical power and gas to water, telecoms and broadband cables. It acts like a shield, guarding these cables against ground movement, moisture and any accidental damage during installation or maintenance. This protection helps keep our everyday utilities running smoothly and safely.

You’ll often see ducting in different colours, which isn’t just for aesthetic appeal. Essentially, each colour helps identify the type of service inside. This makes future maintenance easier and helps avoid costly mix-ups. Whether it’s power lines, gas pipes or fibre optic cables, ducting is the unsung hero that keeps essential infrastructure safe across businesses and industrial sites.

WHY USE IT? / IMPORTANCE

Organisation & Tidiness

For every building you see, they make use of utilities and services, delivered through pipework and cabling. There are millions of buildings and millions of miles of cables in the UK as well as in any other country worldwide. It would be practically impossible to leave all those cables on the ground. Therefore, burying cables can be a neat, tidy and organised cable routing solution, especially in dense areas.

Protection

Apart from aesthetic benefits, underground ducting protects water pipes, gas pipes and electric cables from damage. And more importantly, they protect people from their (potentially harmful) contents.

If left unprotected and above ground, cables and pipes are exposed to weather and environmental factors. That increases the risk of cables/pipes being crushed, broken, tampered with or compromised. This could also present a risk to the safety of people coming in contact with them. Exposure to a damaged electric cable could result in a harmful or even fatal electric shock. Burying below ground reduces many of these risks and simultaneously slows down the effects of weathering on the cable.

However, even when installed below the ground, pipes and cables can still be damaged by other factors, like root growth, or by individuals accidentally digging where they are placed. That’s where underground ducting comes in super handy. By running utility pipes and cable through ducting pipes, it provides an extra layer of protection and insulation against any type of damage or potentially harmful occurrence.

Saving Time & Money

Another essential benefit is that underground ducting saves time and money. When installed correctly, services like electricity, water, gas, internet and phone lines can all run smoothly without interruption. Additionally, any type of maintenance or repair work becomes easier. That increases general operational safety and reduces project costs considerably.

Leakage Prevention

Last but not least, another important reason for using underground cable ducting is that it’s a great way to ensure any substance leaking from cables doesn’t immediately affect water or other nearby sources. Both overground and underground cables can leak and ducting is a good solution to prevent any potential contamination.

DUCT INSTALLATION METHOD

Ever wondered how to install underground utilities ducting?

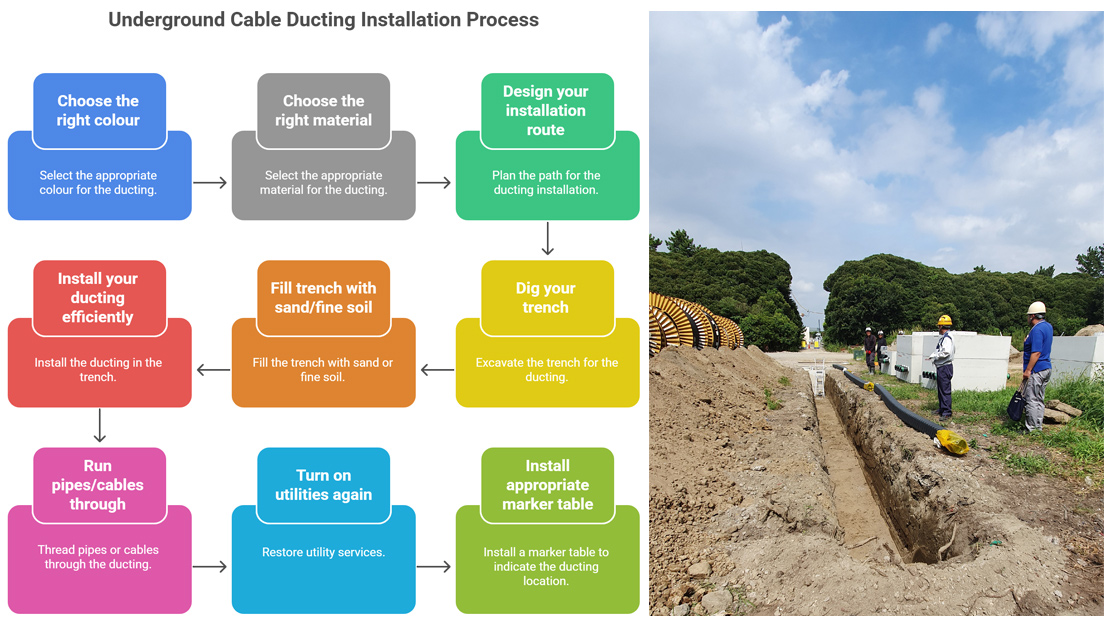

Installing ducting is simple, but doing it safely and compliantly takes planning. Before digging, confirm your route with utility maps. Also check depth requirements, local regulations and nearby services. Skipping this can cause delays or hazards, so always get the right permissions first. Ducting must suit the application — LV/HV power, fibre or EV charging — each with its own colour, size or material spec. Some installs need multiple ducts. Choosing correctly upfront makes installation and future maintenance easier.

Then, excavate to the correct depth and width. Please note, this varies by service type and surface. For example, road crossings require deeper trenches than verges. You should ensure a flat base, adding sand if ground is uneven or stony. Most systems — like twinwall or rigid PVC — assemble quickly with bends and couplers. But make sure you have watertight joints, stable support and a draw rope if cables come later. Then, you should surround with fine soil or sand before backfilling to protect against movement or damage.

iStep 9 – Checking the installation to ensure everything is connection and sealing is correct.

Every manufacturer, however, has some additional steps or differentiators in this process according to their solutions’ requirements. To download the Installation Manual for the Furukawa Electric EFLEX Square Ducting System, please follow the link below:

LAWS & REGULATIONS

What does the law say about underground ducting?

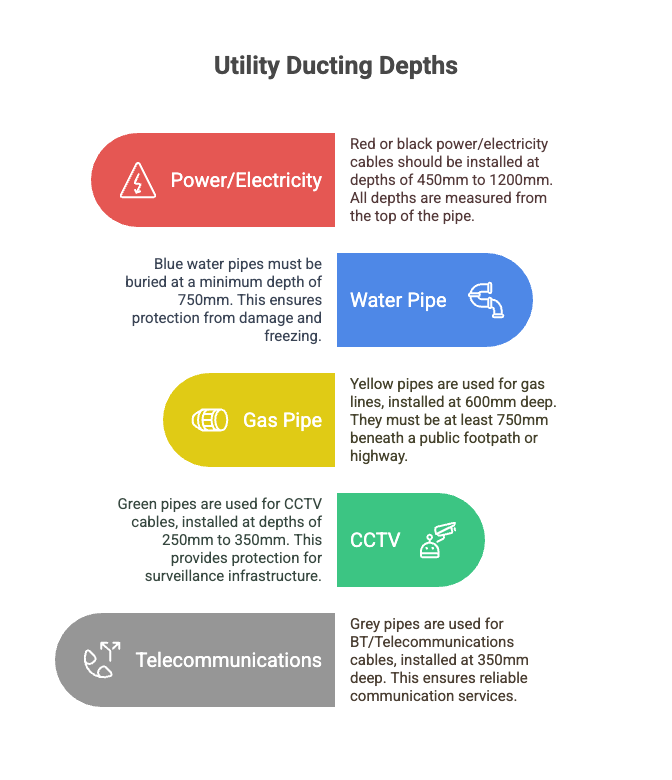

Legislation for installing underground cables and utilities focuses on ensuring minimum installation depths for the relevant pipes and cables. Another legal requirement of underground ducting is to use the right ducting colour for the appropriate utility. Additionally, cables and pipes must be installed into ducts that are suitably-sized to accommodate their diameter. Before installation takes place, all cable ducts should be checked and cleared of obstructions. To ensure that the duct is suitable for the type of installed cable, UKPN (UK Power Networks) recommend:

- Pulling a 3-metre sample of the LV-HV cable – identical to the one intended for final installation – through the full length of the duct to test the route

- Examining the duct for any cracks or damage before proceeding to pull and install the complete cable length

- If the sample cable shows deep scores or tears in the outer sheath exceeding half its thickness, the duct route must be repaired before installing the final cable

The usage or continuation of usage of any underground cable/pipe or attached equipment that does not comply with the current laws and regulations is illegal. The prosecution of anyone responsible is possible.

What are underground ducting colours codes and why are they important?

The reason each pipe is a different colour is purely for safety reasons, building regulations and to identify which ducting is protecting which type of cable.

The colour codes are useful during excavation or if any repairs are necessary in underground utilities networks. Particularly, they aim to reduce the chance of damaging underground services while also minimising the risks of anyone involved in this work. It’s important to know and adhere to the UK’s universal ducting cable colour codes.

There are minimum depth requirements for all underground utility ducting. Please consult Utility Ducting Depths image. (All depths indicated are from the top of the pipe to finished ground level.)

Additional Sources

For more information on the rules and regulations surrounding underground utilities, we suggest visiting the Street Works UK website. This Government site provides publications with specific guidance tailored to the location and intended use of underground cables. For example, guidelines around positioning underground utilities in new developments feature in Volume 2, while information regarding the management of third-party ducting feature in Volume 3.

Another useful and reliable source is the HSE Legislations website. HSE offers more information on excavation and underground services. This includes guidance on safe digging practices and using a cable locator to verify site plans against what’s actually in the ground. Professionals often recommend using plans as a starting point to locate underground cables, but warn against relying on them as definitive.

FURUKAWA ELECTRIC CABLE DUCTING & ACCESSORIES

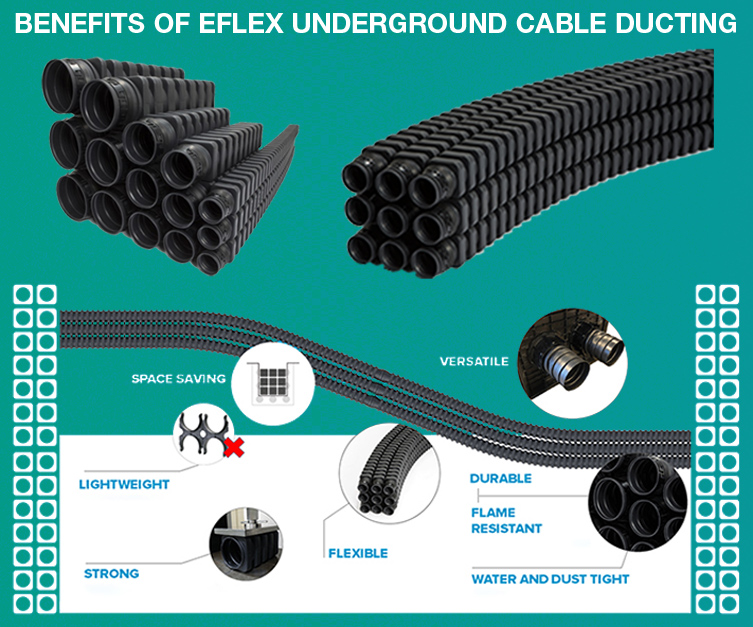

E-Tech Components are a specialist stockist and distributor of EFLEX Square – Furukawa Electric’s Underground Cable Ducting System, the simplest and fastest installation of protected buried cable routes! EFLEX Square complies with ENATS 12/24 Class 1 Specification.

EFLEX Square units are stackable, resulting in fast and simple installation, even in areas with limited space as it requires minimal excavation and no duct spacers. The flexible profile of the ducting means that no bend pieces are necessary. Available in 5 sizes (50,80, 100, 130, 150) the stackable units are supplied in 5.3m lengths with built-in male and female push-fit watertight connectors.

FREQUENTLY ASKED QUESTIONS

Is ducting the same as trunking?

Both cable ducting and trunking protect cables, keep them organised and conceal them from view. However, each one has a variety of uses and applications, with some key differences too.

First of all, Cable Ducting is for outdoor use and underground utility installations. On the other hand, installers mainly use Cable Trunking for indoor cable management. Additionally, the former consists of lengths or coils of pipe, whereas the latter is an enclosure, usually with a rectangular cross-section and a removable (or hinged) side.

Cable trunking is typically visible in office buildings, often appearing as a white plastic box running along walls and roofs. Its purpose is to cover electrical equipment, keeping it safe and tidy. You would never find trunking buried in the back garden. Or with power cables or utility pipes running through it. That is what underground ducting is for!

What are the HS Codes for Cable Ducting?

The HS Code for Trunking, Ducting and Cable Trays used in electrical circuits is 39259020. HS stands for the Harmonized Commodity Description and Coding System, and constitutes an international nomenclature for the classification of products. This code is commonly referred to as the Customs Tariff Number in many countries, where it is used for customs and tariff purposes.

Does Armoured (SWA) Cable need ducting?

There is no need for ducting when installing Steel Wire Armoured (SWA) Cable. You can bury it directly in the ground at a sufficient depth to prevent damage, with no additional protection needed.

However, you can apply a layer of sand or silted soil beneath the cable, then cover it with more sand or silted soil to protect the outer sheath from sharp stones.

Curious to know more about our offerings? Check out our Company Brochure and MV Cable Accessories Catalogue: